Choosing the wrong hinge can cause your door to fail, become damaged, or require costly repairs. If you don’t know the difference between heavy duty and light duty hinges, it’s hard to pick the right hinge for your application. You could have problems with your hinge and/or damage your door.

Heavy duty hinges support heavier doors and take more abuse. Light duty hinges are for lighter doors and applications. The difference is in the materials, strength, and weight capacity.

Now, let’s look at the differences between heavy duty and light duty hinges and how to choose the right one.

What are Heavy Duty Hinges?

Definition and Materials:

Heavy duty hinges are crafted for large, heavy doors such as steel or industrial gates. These hinges are made from durable materials like stainless steel, brass, or even carbon steel, enabling them to support significant weight while resisting wear and tear. They are ideal for use in demanding environments, where constant stress and heavy loads are common.

Applications:

Heavy duty hinges are primarily used in industrial settings, including for trailer door hinges or commercial steel doors. They are also used in security gates and heavy-duty storage areas where durability and high load-bearing capacity are essential.

What are Light Duty Hinges?

Definition and Materials:

Light duty hinges are designed for smaller, lighter doors often found in residential environments. These hinges are usually made from lighter materials such as aluminum or lower-grade steel, which are sufficient for handling less weight.

Applications:

You’ll typically find light duty hinges used in interior doors, small gates, or cabinetry. They are perfectly suited for applications where the door or object doesn’t bear much weight and won’t face frequent heavy use. For example, a butt hinge is often used in interior household doors, providing reliable performance in low-stress environments.

Key Differences Between Heavy Duty and Light Duty Hinges

Weight Capacity:

The most significant difference between heavy duty and light duty hinges is the weight they can support. Heavy duty hinges can hold doors weighing several hundred pounds, whereas light duty hinges are intended for doors weighing less than 100 pounds. Heavy duty hinges are critical for supporting large, steel doors or cold storage room hinges, which must maintain integrity under intense use.

Durability and Stress Endurance:

Heavy duty hinges are built to withstand significant pressure and continuous usage. They can handle high-traffic areas and rough conditions, making them perfect for exterior gates or security doors. In contrast, light duty hinges are designed for less frequent use and can wear out more quickly under constant stress or if used for heavier doors than intended.

When to Use Heavy Duty Hinges?

Industrial and Commercial Settings:

Heavy duty hinges should be used in industrial environments, such as factories or warehouses, where doors are frequently opened and closed and may carry considerable weight. These hinges are also essential for marine hinges that are exposed to corrosive environments and heavy stress.

Heavy Duty Gates and Shed Doors:

For outdoor applications like shed doors or large security gates, heavy duty hinges ensure the structure remains secure and functional over time. Their reinforced construction allows them to maintain performance even under harsh conditions, such as extreme weather.

When to Use Light Duty Hinges?

Residential and Low-Stress Applications:

Light duty hinges are better suited for residential use or interior doors, such as those in bedrooms or bathrooms. They provide the necessary support for lighter doors that don’t require the extra strength of heavy-duty options.

Home Applications:

In settings like cabinets or small gates, where weight and stress are minimal, light duty hinges will suffice. They offer smooth operation and a visually appealing design without the added cost and strength needed for heavier doors.

Strength and Structure of Heavy Duty Hinges

Reinforced Design:

Heavy duty hinges often feature multiple pins and bearings that allow the hinge to function smoothly under high pressure. This structure prevents sagging and ensures long-term durability, even with constant use. Some heavy duty hinges, like weld on hinges, are specially designed for industrial doors where additional support is needed to maintain structural integrity.

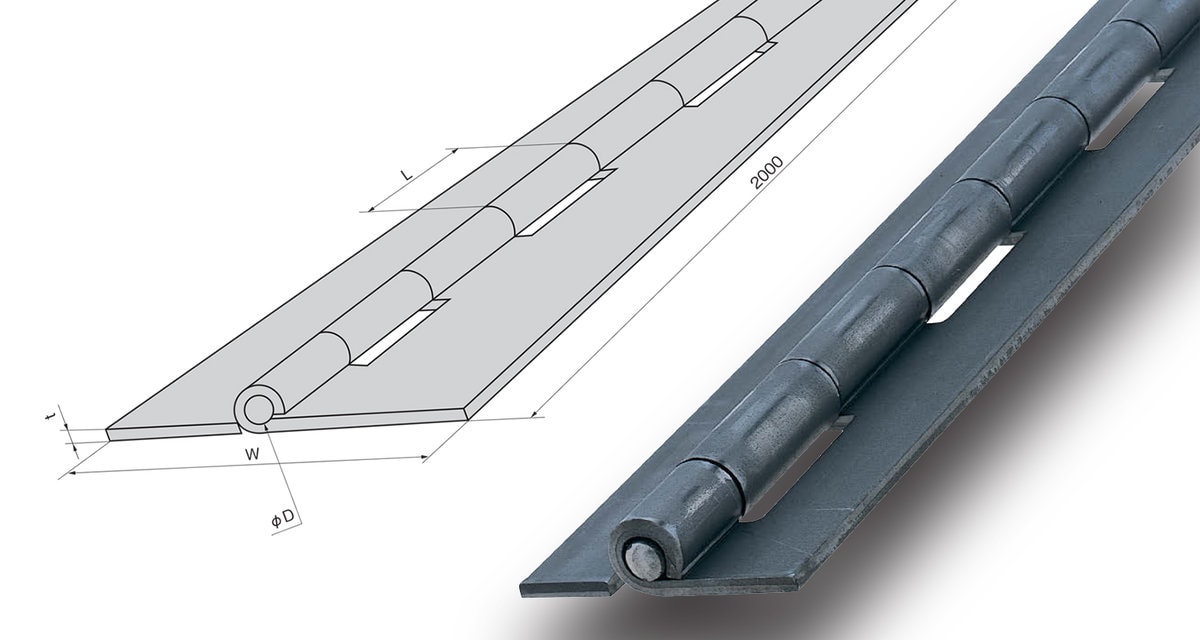

Types of Heavy Duty Hinges:

Popular examples include continuous hinges, which are used for longer doors, and detachable hinges, allowing doors to be easily removed when necessary. These types of hinges provide versatility and strength for specific industrial or commercial needs.

Strength and Structure of Light Duty Hinges

Simpler Design:

Light duty hinges typically have a simpler design, featuring fewer pins and a basic knuckle and pin structure. This basic design is adequate for lighter doors and ensures a smooth operation without the need for added reinforcement.

Common Styles:

Light duty hinges are frequently seen as butt hinges or cabinet hinges, used in residential settings where visual appeal and functionality are important. They come in a variety of finishes to match home décor while maintaining smooth operation for lightweight doors.

Material Considerations for Heavy Duty Hinges

Stainless Steel and Brass:

Heavy duty hinges often feature stainless steel or brass materials that provide corrosion resistance and longevity. This makes them ideal for exterior doors or applications that need to withstand harsh weather conditions, such as marine hinges exposed to moisture and saltwater.

Additional Coatings:

To ensure even greater durability, heavy duty hinges may come with powder coatings or galvanization to protect against corrosion and wear, extending the lifespan of the hinge in demanding environments.

Material Considerations for Light Duty Hinges

Aluminum and Lower-Grade Steel:

Light duty hinges are often crafted from aluminum or lower-grade steel, which is sufficient for lighter, interior doors. These materials are chosen for their cost-effectiveness and ability to support basic door functions without adding unnecessary weight or strength.

Aesthetic Choices:

Since light duty hinges are often used in visible home environments, they come in a variety of finishes and styles to match home décor. Homeowners can select the style that best fits their interior design while ensuring smooth functionality.

Choosing the Right Hinge for Your Application

Assess the Door Weight and Use:

Before selecting a hinge, consider the weight and material of the door, as well as how frequently it will be used. Heavier doors in commercial settings require heavy duty hinges, while lighter residential doors can make use of light duty alternatives.

Environment and Exposure:

It’s also essential to consider environmental factors. Outdoor and industrial applications should use heavy duty hinges that resist weathering and corrosion, whereas indoor doors can rely on lighter duty options for optimal performance.

In Conclusion

Understanding the differences between heavy duty and light duty hinges is critical for selecting the right option based on door weight, materials, and intended usage.