Removing them the wrong way can lead to damaged equipment, injury, or misalignment of industrial doors, causing a slowdown in your operation. The solution? A step-by-step process for removing them safely and efficiently.

To remove spring-loaded door hinges in industrial equipment, you release the spring tension. Next, you remove the hinge pin. Finally, you carefully remove the hinge without damaging anything around it.

Now, let’s get into the specifics of how to remove spring-loaded door hinges.

Understanding spring-loaded door hinges

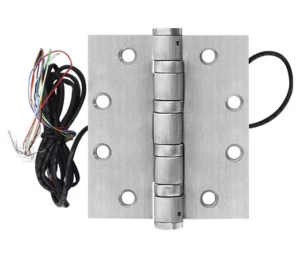

Spring-loaded door hinges are a common component in industrial equipment that provide an automatic door closer to help maintain operation in a high-traffic environment. This reduces the number of times you have to manually close a door. You will find these in industries with heavy machinery, in temperature-controlled environments, or where safety is a concern.

What makes them different from the ones you might see in a residential setting is they are bigger and beefier. Because of their robust construction, they sometimes require extra steps to remove them. If you don’t understand how the springs work or what they do, you can damage the equipment or the door.

Tools Required for Removing Spring-Loaded Hinges

Before beginning the removal process, make sure you have the following tools at hand:

- Allen key (for hinges with an Allen screw)

- Hammer or mallet

- Screwdriver

- Punch tool

- Lubricant (optional, for stuck pins)

- Safety gear (safety glasses, gloves)

Having the right tools is essential for precision. Without them, you may struggle to release the spring tension or remove the pin without causing damage. Be sure to inspect the hinge to determine the correct tool before proceeding.

Step-by-Step Guide for Releasing Spring Tension

The first step in removing spring-loaded hinges is to release the spring tension. For most industrial hinges, this involves locating the tension adjustment hole, typically found on the side of the hinge. Insert the appropriate-sized Allen key into the hole.

Turn the Allen key counterclockwise to gradually release the tension in the spring. Continue turning until the spring no longer holds tension. Failing to release this tension can cause the hinge to snap back unexpectedly, which may lead to injury or equipment damage. Repeat this step for all spring-loaded hinges on the door.

How to Remove the Hinge Pin

After the spring tension has been fully released, proceed to remove the hinge pin. In industrial doors, the pin can be larger and more tightly fitted than in standard residential doors. To remove it, place a punch tool or screwdriver at the bottom of the pin.

Lightly tap the punch tool with a hammer or mallet to dislodge the pin. If the pin does not budge, apply a small amount of lubricant to ease the process. For hinges with non-removable pins, consider unscrewing the hinge from the door entirely. Make sure the door is supported to avoid accidents while removing the pin.

Safely Detaching the Hinge from the Door Frame

With the pin removed, the hinge can now be detached from the door frame. Gently pull the hinge away from the frame, taking care to support the weight of the door if it is heavy or awkward to maneuver.

In some industrial settings, the door may be too large to handle alone. In such cases, have an assistant or use equipment like a door jack to hold the door steady while you work. Slowly removing the hinge will ensure that you don’t damage any surrounding components, such as sensitive electrical parts or panels attached to the door.

How to Handle Self-Closing Spring Hinges

Self-closing spring hinges, often found in automatic door-closing systems in industrial environments, require special care during removal. These hinges are designed to close doors automatically, preventing airflow or ensuring safety in specific settings.

To remove self-closing hinges, follow the same initial process of releasing spring tension and removing the hinge pin. Be cautious, as the internal springs in these hinges are often more tightly wound than standard spring-loaded hinges. Double-check that the spring tension is fully released before proceeding to avoid potential injury.

Removing Heavy-Duty Spring Hinges

Heavy-duty spring hinges are larger, more durable, and built to handle the weight and constant movement of industrial doors. Removing them involves a similar process but requires greater attention to safety and support.

Before removing the hinges, ensure that the door is securely supported. Industrial doors can weigh hundreds of pounds, so removing hinges without proper support may result in accidents or damage to the surrounding equipment. If necessary, use heavy-duty equipment or additional personnel to assist in the removal.

Troubleshooting Common Issues When Removing Hinges

If you encounter difficulties during hinge removal, such as a stuck pin or hinge, it’s essential to troubleshoot properly. Common problems include:

- Rust or corrosion: Apply a penetrating lubricant to loosen the hinge pin or screws.

- Tight-fitting pins: Use additional force, such as a hammer, to drive out stubborn pins carefully.

- Misalignment issues: If the hinge refuses to detach, ensure that the spring tension is fully released and check for any secondary locking mechanisms.

If the hinge is still immovable, consider using a heat gun to expand the metal or, as a last resort, cutting tools to remove severely rusted or corroded hinges.

Replacing or Reinstalling Spring-Loaded Hinges

Once the spring-loaded hinge is removed, you may need to replace it or reinstall a new hinge. Reinsert the new hinge in the same position, ensuring it is properly aligned with the door frame.

After positioning the new hinge, insert the pin and adjust the spring tension to the desired strength. Gradually test the hinge to ensure it closes the door properly. In industrial settings, improper installation can cause misalignment, leading to operational inefficiencies or safety hazards.

Safety Considerations for Removing Hinges in Industrial Settings

Safety should always be the top priority when removing spring-loaded hinges in industrial equipment. Wear safety glasses and gloves to protect yourself from flying debris or accidental pin dislodgment.

If the door is too heavy to manage alone, use proper lifting equipment or enlist the help of a team. Ensure that the work area is clear of obstructions and other workers before beginning the hinge removal process to avoid accidents.

Conclusion

It’s important to remove these properly so you don’t damage anything and so you don’t hurt anybody or anything.