Purchasing the right stainless steel door hinges might seem straightforward, but it’s a decision that carries more weight than you might expect. These small components play a crucial role in the functionality and longevity of your doors.

Selecting the appropriate hinges for your stainless steel door is not just about aesthetics; it involves understanding the door’s physical attributes, the relationship between the door and its frame, installation nuances, and customization options. By considering these factors, you ensure your door operates smoothly, safely, and efficiently.

As you continue reading, you’ll discover key insights that will guide you through the process of selecting the perfect hinges for your stainless steel door, ensuring a blend of functionality, durability, and style.

What is the Weight of the Stainless Steel Door?

The weight of your stainless steel door is the primary factor in choosing the right hinges. A heavier door requires stronger hinges to support it without sagging or causing strain. To accurately gauge the weight, you can refer to the manufacturer’s specifications or use a scale for an existing door. It’s crucial to note that the weight directly influences the type, size, and number of hinges needed.

For light to medium-weight doors, standard hinges are usually sufficient. However, heavier doors demand more robust hinges, possibly with bearings for smoother operation. The material of the hinge itself is also vital – stainless steel hinges are preferred for their strength and corrosion resistance, especially in high-humidity or coastal areas. Precision in weight assessment ensures the longevity and functionality of your door.

What is the Height of the Stainless Steel Door?

The height of your stainless steel door plays a critical role in determining the number of hinges required. Standard doors typically require two to three hinges. However, taller doors, often over 84 inches, may need additional hinges to distribute the weight evenly and maintain structural integrity.

As a rule of thumb, add one hinge for every additional 30 inches in height beyond the standard size. This calculation helps prevent the door from sagging or becoming misaligned over time. It’s also important to consider the door’s usage frequency – doors that are used more frequently may benefit from an extra hinge for added support.

The Positional Relationship Between the Door and the Door Frame

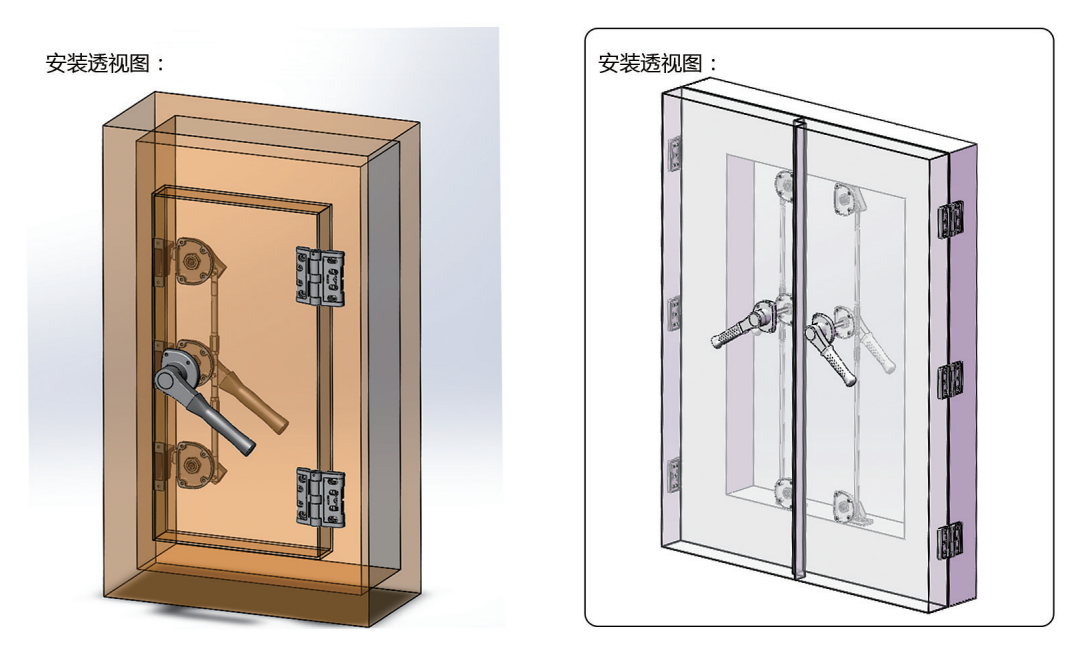

The positional relationship between the door and the door frame, whether flush or with a drop (offset), significantly affects the hinge type and installation. Flush doors sit level with the frame, requiring hinges that allow for a seamless opening. In contrast, doors with a drop are not level with the frame and need hinges that can accommodate this offset.

For flush doors, butt hinges are commonly used as they sit flat against the door and frame. For doors with a drop, pivot or specialty hinges might be required to align the door correctly with the frame. It’s important to understand this relationship to ensure the door operates smoothly without scraping or misalignment.

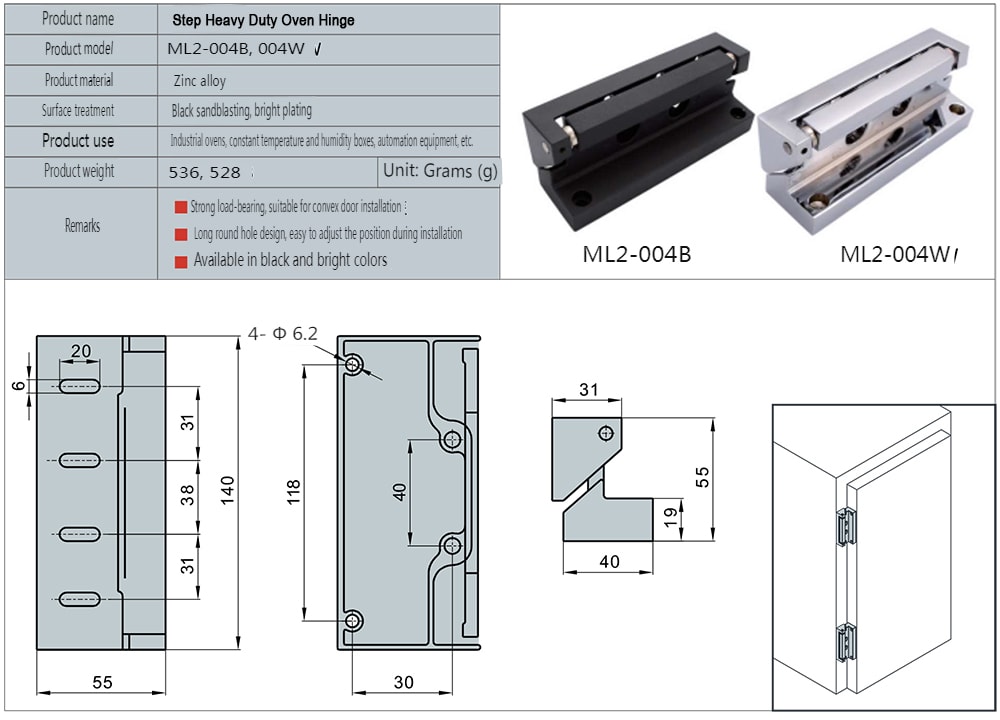

For example, this is an industrial oven hinge that is specially designed for use on equipment doors where the door panel has a drop to the door frame. It is used on industrial oven doors and has good load bearing properties.

The Way the Hinges are Installed

Proper installation of hinges is as important as selecting the right type. There are different installation methods, such as screw-on, weld-on, or bolt-on, each suitable for different door types and usage scenarios.

Screw mounting is usually used, but some devices are special and require strong connections and load-bearing capacity. This requires welded mounting. We call these hinges welding hinges.

For those not experienced in DIY projects, professional installation is recommended. Professionals can ensure that the hinges are aligned correctly, evenly spaced, and securely attached, which is crucial for the door’s functionality and safety.

Do You Need to Customize It?

In some cases, standard hinges might not meet the specific requirements of your door. Custom hinges can be designed to accommodate unique sizes, weights, or aesthetic preferences.

Customization might involve special sizes, finishes, or additional features like self-closing mechanisms. While this option might be more costly, it ensures that the hinges are perfectly tailored to your door’s specific needs.

Conclusion

Choosing the right hinges for your stainless steel door is a decision that impacts not just its functionality but also its longevity and ease of use. By considering these five key factors, you are equipped to make an informed choice, ensuring your door operates optimally for years to come.

You might be interested: