Piano hinges, often misinterpreted in their usage and capabilities, are essential components in various mechanical and structural applications. This article aims to clarify common misconceptions and highlight the true versatility and efficiency of piano hinges in various settings.

Piano hinges, also known as continuous hinges, are integral in a myriad of applications, extending well beyond their traditional use in musical instruments. They are designed for even weight distribution and heavy-duty usage, debunking the myth of their limited utility.

Exploring these hinges in-depth reveals their adaptability and importance in both common and specialized applications, encouraging more innovative uses in diverse projects.

Myth 1: Prone to Deformation

A common misconception is that piano hinges are easily deformable due to their length. In reality, the design of piano hinges distributes stress evenly along their entire length, which significantly reduces the risk of deformation. This is particularly advantageous in applications where the hinge must maintain its shape and functionality under constant use and varying stress levels.

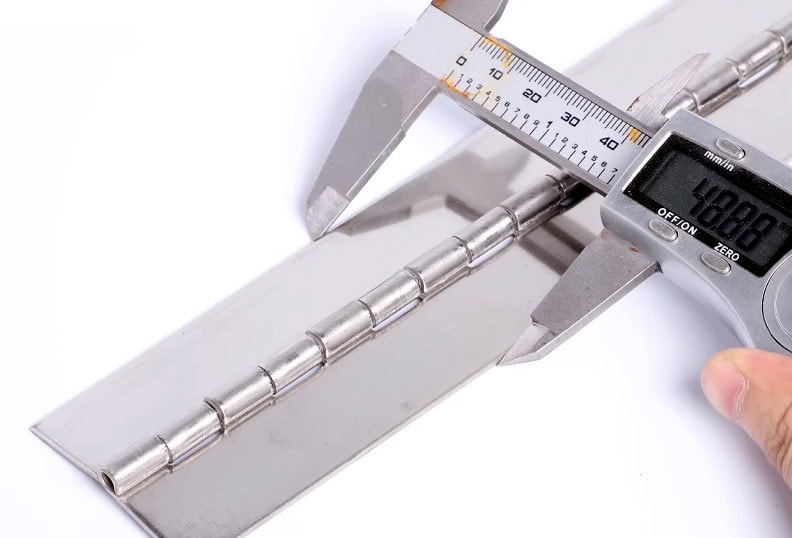

Moreover, the material and thickness of the piano hinge play a crucial role in its resistance to deformation. High-quality piano hinges are crafted from durable materials like stainless steel or reinforced aluminum, ensuring they retain their shape and effectiveness over time, even in challenging environments.

Myth 2: Difficult to Install

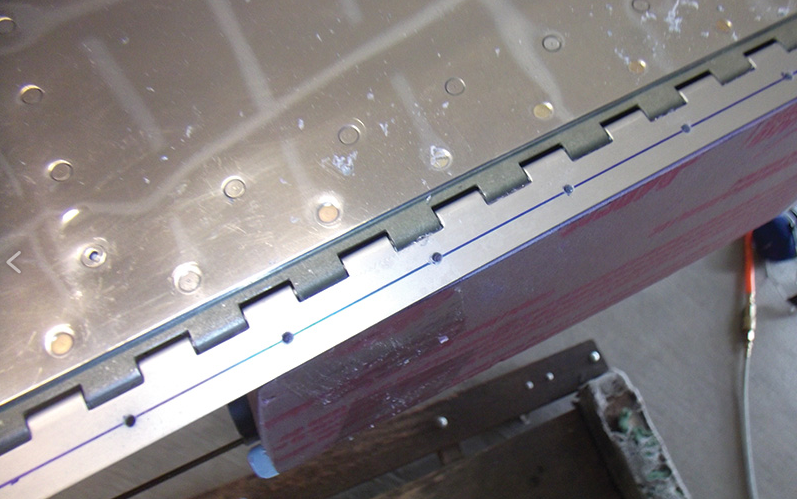

Another widespread belief is the difficulty in installing piano hinges. Contrary to this, piano hinges offer a straightforward installation process. Their design allows for alignment along the entire edge of the connecting surfaces, providing a stable and accurate guide for installation.

For installations requiring precision, piano hinges can be easily adjusted and aligned, ensuring a seamless fit. Their versatility in installation methods, including screwing and welding, allows them to be securely attached to a wide range of materials, making them a practical choice for both professional and DIY projects.

Myth 3: Lack of Stability

The length of piano hinges often leads to the misconception that they are unstable. However, this extended design is precisely what provides enhanced stability. By distributing the load along the entire length of the hinge, piano hinges ensure a balanced and stable connection between the joined surfaces, which is especially beneficial for heavy or frequently used doors and lids.

In high-stress applications, the stability offered by piano hinges is unmatched. Their ability to sustain heavy loads without compromising functionality makes them a reliable choice for industrial and commercial uses where durability is paramount.

Myth 4: Limited Customization

The myth of limited customization with piano hinges is far from the truth. These hinges offer extensive customization options to suit specific applications. They are available in various lengths, widths, materials, and finishes, catering to a wide range of functional and aesthetic requirements.

Additionally, piano hinges can be custom-made with or without holes, tailored to specific weight capacities, and even treated for additional corrosion resistance. This level of customization makes them suitable for specialized applications, from bespoke furniture to tailored industrial machinery. In fact, IHINGES is a manufacturer that specializes in custom-made industrial hinges.

Myth 5: For use in pianos only

Piano hinges, though named for their common use in pianos, have a much broader scope of application that extends far beyond the realm of musical instruments. Their structural design and durability make them an essential component in various everyday objects. For instance, in the home, piano hinges are frequently used in cabinetry and furniture.

Their length allows for a more stable and uniform support, particularly for long cabinet doors or storage chests, ensuring that the doors open and close smoothly without sagging. Additionally, their sleek and continuous appearance offers a more aesthetically pleasing and less obtrusive look compared to traditional hinges, enhancing the overall design of the furniture.

In more specialized applications, piano hinges demonstrate their versatility and robustness. In the realm of medical equipment, for instance, they are employed in the construction of heavy-duty medical cabinets and storage units, ensuring that these high-use doors can withstand frequent opening and closing without failure.

In the automotive industry, piano hinges are used in the construction of vehicle doors, hatches, and engine covers. Their ability to distribute weight and stress evenly across their length makes them particularly suitable for these applications where durability and reliability are paramount.

This wide-ranging usability in various industries and products effectively dispels the myth that piano hinges are confined to the use of musical instruments, showcasing their integral role in numerous aspects of everyday life and specialized machinery.

Myth 6: Only steel is used as material

The versatility of piano hinges is further exemplified in the variety of materials from which they are made, challenging the common misconception that they are only available in steel. While steel piano hinges are indeed popular due to their strength and durability, other materials like aluminum and brass are also widely used, each offering unique advantages. Aluminum piano hinges, for example, are much lighter than steel, making them an ideal choice for applications where weight is a concern, such as in aircraft or lightweight cabinetry.

They also resist corrosion better than steel, which is crucial in environments exposed to moisture or chemicals, like marine applications or outdoor settings. Brass piano hinges, on the other hand, are known for their aesthetic appeal and corrosion resistance, commonly used in decorative furniture, luxury packaging, and architectural details where the hinge is a visible part of the design.

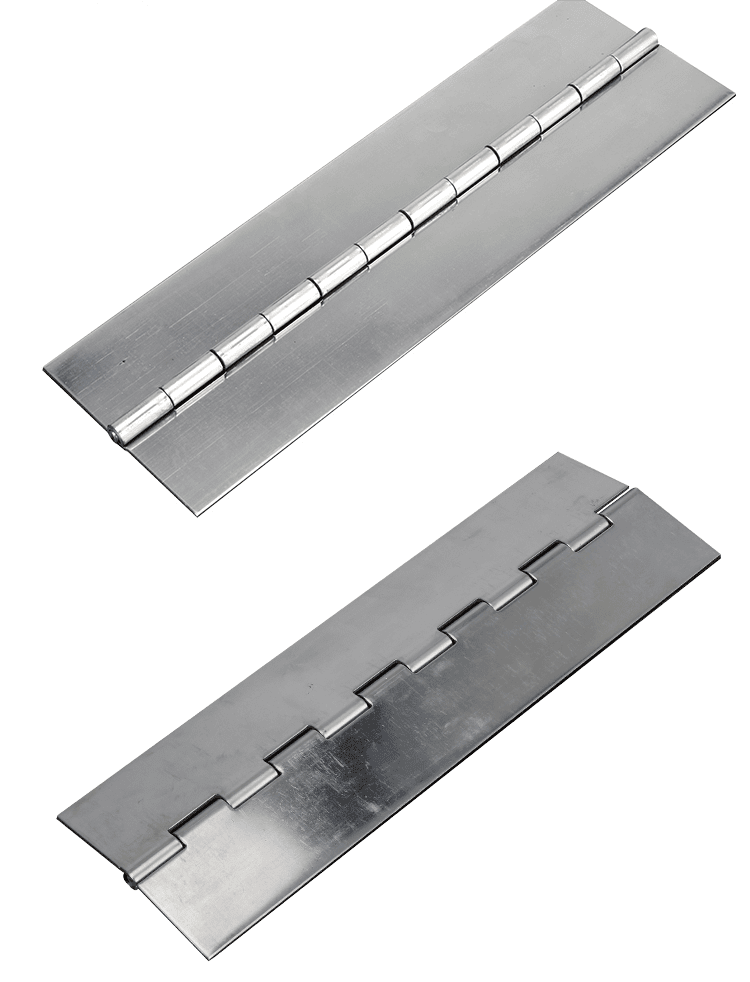

In addition to material diversity, the customization options available for piano hinges further enhance their adaptability. These hinges can be manufactured with or without pre-drilled holes, offering flexibility in the method of installation. Hinges without holes are often used where a seamless appearance is desired or in applications where welding is the preferred method of attachment, such as in certain types of metalwork or when a more permanent, tamper-proof installation is required.

Hinges with pre-drilled holes provide convenience and ease of installation with screws or rivets, which is particularly useful for DIY projects or situations where the hinge may need to be removed or adjusted in the future. This level of customization not only makes piano hinges suitable for a wide range of applications but also allows for specific tailoring to the unique requirements and constraints of different projects, dispelling the notion that piano hinges offer limited options and highlighting their adaptability and suitability for various uses.

IHINGES can customize industrial hinges in different materials, which require different production equipment. For example, industrial oven hinges are generally made of zinc alloy and are produced using die-casting machine equipment.

Myth 7: Low strength and durability

The design of piano hinges inherently caters to high-strength and heavy-load applications, effectively debunking the myth that they are unsuitable for such purposes. The key to their strength lies in their extended length, which allows for an even distribution of weight and stress along the entire span of the hinge. This uniform distribution prevents the concentration of stress at any single point, a common issue with shorter hinges that can lead to premature wear or failure.

As a result, piano hinges maintain their integrity and functionality under the strain of heavy doors, panels, or lids, making them an ideal choice for industrial applications such as warehouse doors, heavy machinery covers, or large access panels in aircraft and vehicles.

In addition to the physical design advantages, the material composition of piano hinges contributes significantly to their load-bearing capacity. Hinges made from high-grade steel or reinforced alloys offer exceptional strength and resilience, capable of supporting substantial weights without bending or breaking. This robust construction is crucial in settings where safety and reliability are paramount, such as in emergency exits, heavy-duty vehicles, or safety equipment. The ability of piano hinges to withstand rigorous use and heavy loads also extends their lifespan, reducing the need for frequent replacements and maintenance, a crucial factor in cost-sensitive industrial environments.

Furthermore, the adaptability of piano hinges in terms of their size and thickness allows them to be tailored to specific weight requirements. For extraordinarily heavy applications, thicker and wider piano hinges can be utilized to provide additional support. This customization capability ensures that no matter how heavy the load, there is a piano hinge configuration that can handle it efficiently.

Their reliability under heavy loads extends beyond mere functionality; it also enhances the overall safety and stability of the structures and equipment they are used in. This combination of design, material strength, and customization options makes piano hinges not just suitable, but often the preferred choice for heavy-load applications, offering unparalleled durability and stability where traditional hinges would falter.

Conclusion

Piano hinges are a prime example of simplicity combined with versatility. By debunking these common myths, we uncover their true potential in various applications, ranging from everyday use to specialized industrial requirements. Understanding their capabilities allows for more effective and creative utilizations in numerous projects.

You might be interested: