The industrial world often grapples with the choice between chrome steel and stainless steel. This decision is far from trivial, as the two materials, though superficially similar, offer distinctly different properties and benefits. This comprehensive guide delves into the nuances of each, helping you make the best choice for your specific industrial needs.

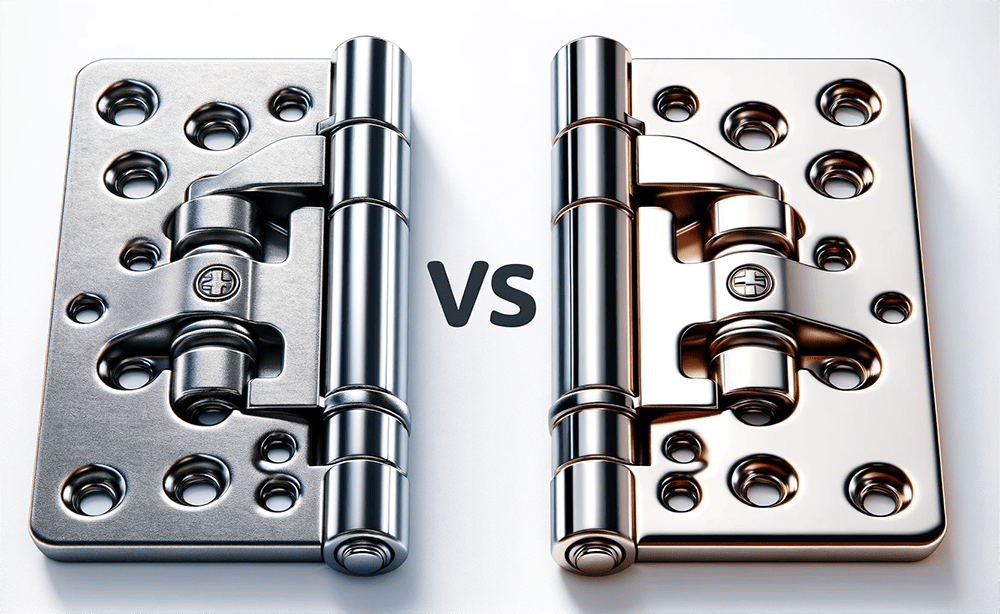

Chrome steel and stainless steel differ fundamentally in their composition, appearance, and performance. Chrome steel is steel coated with a layer of chromium, giving it a distinctive shine and some rust resistance. Stainless steel, however, is an alloy containing chromium, nickel, and other elements, offering superior durability and corrosion resistance.

Choosing the right material is essential for the success of any industrial project. Chrome steel, with its aesthetic appeal, is suitable for projects where appearance is key. For environments demanding high durability and corrosion resistance, stainless steel stands out as the ideal choice.

What is Chrome Steel?

Chrome steel is celebrated for its striking shiny finish, a result of chromium plating. This process involves applying a chromium layer over steel, enhancing its resistance to rust and making it a popular choice for decorative purposes.

Composition and Properties

At its core, chrome steel is essentially steel with a chromium coating. This layer, although offering some protection against corrosion, is thin and can be compromised, leading to rust if the steel is exposed to harsh conditions.

Uses and Limitations

Chrome steel is often used in applications where aesthetics are crucial, such as in automotive trim and kitchen appliances. However, its susceptibility to corrosion in harsh environments limits its use in more demanding industrial applications.

What is Stainless Steel

Stainless steel, a robust and versatile alloy, consists of iron, chromium, and varying amounts of other elements like nickel and molybdenum. Its composition can vary, resulting in different grades with specific characteristics. The butt hinge below is made of stainless steel.

Composition and Grades

The presence of chromium (at least 10.5%) in stainless steel is what imparts its significant resistance to rust and corrosion. Nickel, added in varying quantities, enhances its formability and strength. These variations lead to different grades of stainless steel, each suited to specific applications.

Broad Applications

Stainless steel’s resistance to corrosion, along with its strength and durability, makes it ideal for a wide range of industrial applications. From construction and medical instruments to food processing equipment and chemical containers, stainless steel is a versatile choice.

Durability and Cost Considerations

When comparing chrome steel and stainless steel, it’s important to consider both durability and cost. Chrome steel, while less expensive, may require more maintenance and is less durable. Stainless steel, though initially more costly, offers long-term savings due to its durability and low maintenance needs.

Long-Term Investment

Choosing stainless steel can be a wise long-term investment for industrial applications. Its resistance to corrosion and overall durability mean fewer replacements and repairs, ultimately saving costs in the long run.

Conclusion

Deciding between chrome steel and stainless steel hinges on specific project requirements. For aesthetic appeal and lower initial costs, chrome steel is a viable option. However, for industrial applications where durability, strength, and corrosion resistance are paramount, stainless steel is the superior choice. Your decision should align with the long-term goals and environmental conditions of your project.

You might be interested: