A piano hinge often referred to as a continuous hinge, stands out as a prominent fixture in a wide range of applications. Its unique design and unparalleled function have made it a preferred choice in several industries. What, however, lies beneath its elongated facade that grants it such resilience and versatility? In this exploration, we will delve deep into the anatomy of the piano hinge.

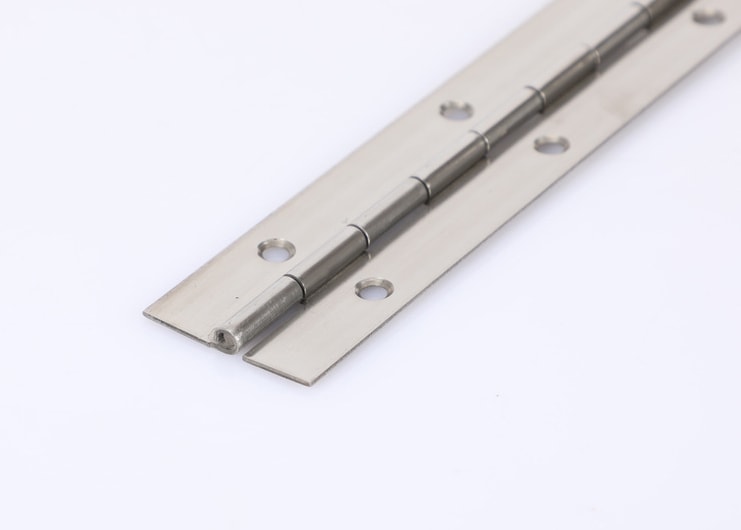

The anatomy of a piano hinge consists of its characteristic elongated length, materials (typically steel, brass, or stainless steel), and components including knuckles, a central pin, hinge leaves, pre-drilled holes for screws or rivets, varied widths and thicknesses, and different finishes. This hinge, originally designed for pianos, has been adopted in various applications due to its resilience and versatility. Its meticulous design ensures both aesthetic appeal and functional durability.

As we journey through its various components, we will unearth the intricacies that contribute to its widespread acclaim and application.

Length

The distinguishing feature of the piano hinge is its impressive length, often matching or exceeding the full span of the items it binds. This extensive length ensures that weight and force are dispersed evenly across the hinge. The result? A reduction in the concentration of stress at any one point. Furthermore, the distributed nature of the hinge means that it offers enhanced support over its entire length, thus facilitating a smooth, consistent motion.

Material

Piano hinges are primarily fabricated from materials such as steel, brass, or stainless steel. Each material lends the hinge certain properties. For instance, stainless steel is renowned for its anti-corrosion characteristics, which makes it perfect for moist or wet settings. Brass, on the other hand, may not be as sturdy, but it often wins points for its aesthetic charm and vintage appeal.

Knuckles

Knuckles, the cylindrical loops that encase the pin, are critical to the hinge’s function. These elongated knuckles in a piano hinge guarantee a snug fit around the pin, creating a sturdy bond. This tight configuration serves as a preventive measure against unexpected detachment, ensuring that the hinge’s motion remains consistent and smooth.

Pin

At the heart of the hinge lies the pin—a central rod that threads through the knuckles, binding the hinge leaves together. The integrity and robustness of this pin play a pivotal role in the hinge’s durability and efficiency. Often, the pin is crafted from a material that matches the hinge, ensuring harmonized strength and longevity.

Hinge Leaves

Adjacent to the knuckles are the hinge leaves—flat extensions that run the length of the hinge. These leaves are vital because they serve as the attachment points to the respective objects being linked. Their long design mirrors the overall dimensions of the hinge, and their robustness is integral to the hinge’s overall stability and function.

Holes

Scattered along the hinge leaves, one will find pre-drilled holes intended for screws or rivets. These holes play a pivotal role in attaching the hinge securely. The uniformity in their spacing and dimensions is not arbitrary—it’s essential for ensuring even force and weight distribution, which in turn augments the hinge’s longevity.

Width

While piano hinges are typically associated with a narrower design, their width can, in fact, vary. Broader hinges are naturally predisposed to support a greater weight, whereas their slender counterparts offer a more subtle, discreet presence, especially in applications where aesthetics are crucial.

Thickness

A hinge’s thickness can be directly correlated to its strength. The denser the hinge, the more weight and stress it can comfortably bear. This makes thicker piano hinges a go-to choice for applications that demand a higher load-bearing capacity.

Finish

Beyond mere aesthetics, the finish of a piano hinge has functional implications. For instance, finishes such as chrome or zinc can significantly boost the hinge’s resistance to corrosion. Meanwhile, a polished or brushed finish might be favored for its visual allure, especially in settings where appearance matters.

Application

Though the name suggests a musical origin, piano hinges have found favor far beyond the realm of instruments. Their robust and adaptable design has led to their incorporation in a multitude of settings, from household doors to intricate machinery parts. Such versatility is a testament to their inherent benefits and the ingenuity of their design.

Conclusion

The anatomy of a piano hinge, with its meticulous construction and well-thought-out components, offers a blend of aesthetics and functionality. By gaining a deeper insight into its structure, we can truly appreciate its myriad applications and the consistency in performance it brings to the table.

You might also be interested: