Picture this: a well-crafted machine or structure, ready for action, but it misses that crucial flexibility because its hinge hasn’t been installed. A hinge might seem like a minor component, but it’s the bridge that offers motion, connecting critical parts.

Hinge installation is an intricate task that demands precision and the right set of tools and techniques. Key tools include measuring instruments, marking tools, drills, screwdrivers, levels for alignment, lubricants, safety gear, and testing equipment. Ensuring the right approach with these tools ensures the hinge not only fits but also functions optimally, facilitating seamless movement in machinery or structures.

Ensuring a hinge works perfectly involves more than just slotting it in. It’s a symphony of precision, the right tools, and an understanding of the techniques involved.

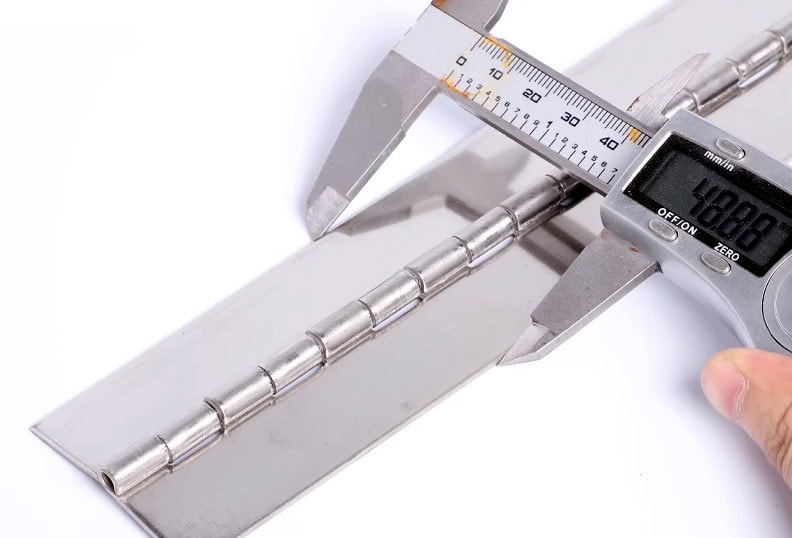

Measuring Instruments

Accuracy is key in hinge installations. Instruments such as rulers, tape measures, and calipers are essential to ascertain the exact positioning and size of the hinge to be installed. Their role can’t be overemphasized.

Delving deeper, precision in measurements ensures the hinge fits perfectly and functions without a hitch. Calipers, especially, allow for detailed measurements down to the smallest millimeter, ensuring an impeccable fit.

Marking Tools

Once measurements are taken, marking the points of installation becomes paramount. Tools like pencils, marking gauges, or chalk come into play, helping delineate the exact spots for hinge installation.

Beyond simple marking, these tools play a role in ensuring alignment. A misaligned hinge can cause operational issues. Hence, precise marking ensures that the hinge aligns perfectly with its counterpart.

Drilling and Boring Tools

Most hinge installations require holes for screws. Drills, along with the right set of drill bits, become indispensable. Their utility is in creating precise holes without damaging the surrounding material.

Additionally, the type and size of the drill bit matter. Using the right bit ensures the screw fits snugly, providing a secure fit for the hinge, essential for its optimal function.

Screwdrivers and Fasteners

Once holes are drilled, the next step is securing the hinge. Screwdrivers, both manual and electric, are needed to drive in screws. The choice of fastener is equally vital, ensuring a tight and durable connection.

The screws’ length and type depend on the material and hinge type. Using the correct fastener ensures longevity and smooth functioning, reducing the chances of wear and tear.

Levels and Alignment Tools

A hinge that’s misaligned will not function correctly. Tools such as spirit levels and plumb bobs ensure that the hinge is perfectly horizontal or vertical, as required.

A deeper look reveals that even a slight misalignment can affect the hinge’s operation. Tools like spirit levels provide visual confirmation of alignment, guaranteeing that the hinge’s movement is unhindered and smooth.

Lubricants and Cleaners

Post-installation, it’s essential to ensure the hinge moves smoothly. Lubricants help in this, reducing friction. Additionally, cleaners are vital to remove any debris or residues from the installation process.

Expanding on their importance, lubricants not only ensure smooth movement but also reduce wear and tear. Cleaners, on the other hand, ensure that no foreign particles hinder the hinge’s operation or cause it to jam.

Safety Gear

Safety can’t be compromised during hinge installations. Protective eyewear, gloves, and even ear protection, depending on the tools used, are vital. They protect against debris, noise, and any accidental slips during the process.

Understanding that installation involves various tools that can cause injury if mishandled, safety gear becomes non-negotiable. It ensures that the process is not only efficient but also safe for the installer.

Testing Equipment

Post-installation, it’s essential to test the hinge’s functionality. Simple manual tests, or for more complex setups, specialized testing equipment, can be used to ensure the hinge operates as intended.

This phase is crucial. Testing confirms that the hinge is not only installed but also operational. Any issues can be identified and rectified immediately, ensuring the hinge’s long-term functionality.

Conclusion

Installing a hinge is more than just fitting a component. It’s a process that demands precision, the right tools, and a deep understanding of techniques. With the right approach and equipment, a hinge becomes more than just a connector; it becomes a silent facilitator of smooth, efficient movement.

For those seeking top-tier hinge solutions, IHINGES is your go-to professional industrial hinge manufacturer. Our unparalleled edge lies in offering unmatched quality at competitive prices. We excel in crafting custom industrial hinges tailored to your equipment needs. Reach out today for a quote and experience the IHINGES difference.

You might also be interested: