In the intricate dance of technology and industry, seemingly small players like hinges play crucial roles. Ensuring the proper functioning of countless devices and machines, these components bear a heavier burden than most might assume.

The answer is a resounding yes. Diverse industries have unique challenges, and the hinges they employ are specifically designed to meet those needs, be it due to environmental concerns, usage frequency, or the need for precision.

From the vast skies navigated by aircraft to the precision required in surgical rooms, specialized hinges facilitate functions vital to our modern world. Read on:

Do Aerospace Industries Utilize Specialized Hinges?

Aerospace, an industry where both weight and strength are paramount, often turns to specialized hinges. Given the unique challenges like atmospheric pressure changes and temperature fluctuations, standard hinges won’t suffice.

Materials like titanium are frequently used, providing strength while keeping weight minimal. These hinges also resist corrosion, crucial when considering the varied environments aircraft endure. The design of these hinges ensures durability, given the crucial safety protocols in aerospace.

Are There Hinges Tailored for Medical Equipment?

The world of medicine is one of precision and sterility. Instruments, especially those used in surgeries, require hinges that can endure repeated sterilization without degrading.

Beyond mere endurance, these hinges offer smooth and precise movement, a crucial feature when the slightest error can have significant consequences. Made of specialized alloys, they can endure high temperatures, ensuring sterilization doesn’t compromise their integrity.

Do Vehicles Have Industry-Specific Hinges?

Vehicles, from the family car to heavy-duty trucks, incorporate hinges designed for frequent use and durability. Their frequent exposure to outdoor conditions demands resistance to environmental wear.

Beyond mere endurance, features like stoppers prevent overextension, ensuring vehicle parts like doors or hoods operate seamlessly. These designs often prioritize both user safety and ease of use, ensuring longevity and reliability.

Are There Special Hinges for Electronics?

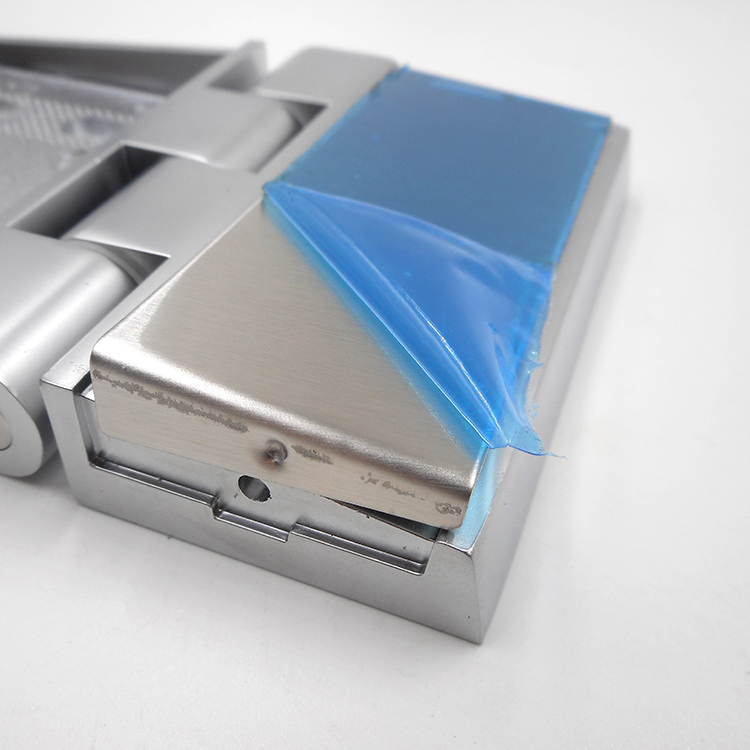

Our electronic devices, from laptops to certain mobile devices, hinge (quite literally) on the proper functioning of their pivot points. Given the frequent motion associated with these devices, the hinges must be both durable and compact.

These hinges are often miniaturized marvels, providing smooth operation while fitting into slim and sleek device designs. The materials chosen often prioritize weight savings without compromising the hinge’s essential function.

Does the Marine Industry Need Special Hinges?

The unforgiving marine environment, characterized by saltwater and persistent moisture, necessitates the use of specialized hinges. Standard hinges would corrode rapidly in such conditions, rendering them useless.

Marine hinges, often forged from stainless steel or brass, provide robust resistance against corrosion. Their designs, while durable, also account for the unique stresses associated with marine movement, ensuring longevity and functionality.

Are There Specialized Hinges for Heavy Machinery?

Heavy machinery operates under substantial stresses, and the hinges they employ need to be up for the task. Designed to bear significant weight and force, these hinges are a testament to engineering prowess.

Constructed from high-strength metals and often treated for added durability, these hinges play a pivotal role in the machinery’s functionality. Their design also integrates safety mechanisms, ensuring no accidental dislodgements occur during operation.

Do Hinges in the Food Industry Have Specific Requirements?

Cleanliness and hygiene are of utmost importance in the food industry. Thus, hinges used in this sector are designed to be easily cleanable, with smooth surfaces that prevent food particle accumulation.

Moreover, materials like stainless steel are chosen for their resistance to bacterial growth and corrosion. This ensures that the food processing or packaging remains uncontaminated, a testament to the hinge’s crucial role in maintaining industry standards.

How About Hinges in the Defense and Security Sector?

In the defense sector, durability isn’t the only concern. Stealth features might be incorporated, ensuring these hinges don’t inadvertently compromise a mission due to reflections or other discernible features.

Designed for ruggedness, these hinges often employ materials that can endure harsh environments. Additionally, the designs might integrate locking mechanisms, vital in certain defense applications where secured positioning is non-negotiable.

Conclusion

The unsung heroes of countless operations, specialized hinges underscore the importance of tailored solutions in diverse industries. Whether braving the salty seas or ensuring a laptop’s smooth operation, these hinges, in their varied designs and functionalities, stand testament to human ingenuity and the intricate dance of industry and technology.

You might also be interested: