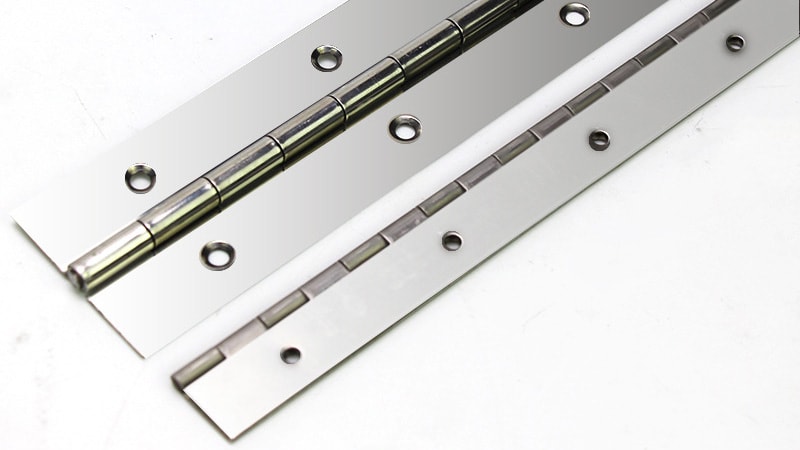

Stainless steel continuous hinges are invaluable components in industrial mechanics beyond their well-known architectural applications.

These hinges offer superior corrosion resistance due to a protective chromium oxide layer, exceptional tensile strength, consistent performance across temperature variations, and aesthetic appeal. Their low maintenance needs, design versatility, long-term economic benefits, and recyclability further make them an excellent choice for various industries, underlining the importance of their features in enhancing operational capabilities.

Comprehensive knowledge of these attributes can drastically transform an industry’s operational capabilities.

Corrosion Resistance

Corrosion often spells doom for metals. But with stainless steel, especially when molded into continuous hinges, the story takes a turn for the better. This shift in narrative is primarily due to chromium’s presence in stainless steel. On interacting with oxygen, chromium initiates the formation of a passive oxide layer on the surface. This isn’t your everyday protective covering; it boasts a self-repairing mechanism.

Whenever there’s a scratch or minor damage, the oxide layer repairs itself, given there’s oxygen available. Such uninterrupted protection across the hinge’s entire length grants it superior resistance, especially in corrosive environments. This trait can be a boon for sectors like marine industries, which constantly grapple with salty, moisture-laden atmospheres.

High Tensile Strength

Strength defines the core essence of stainless steel continuous hinges. Tensile strength, or the resistance of a material to breaking under tension, is astoundingly high in stainless steel. When you blend this innate strength with a continuous design, you’re bestowed with a hinge that resolutely stands against bending, twisting, or breaking.

Without junctions or interruptions, these hinges eliminate potential weak spots. This robust nature finds its true calling in industries that require handling of heavy machinery or where components undergo significant stress. Here, these hinges not only serve but thrive.

Temperature Resistance

In the realm of temperature extremities, many materials buckle. But stainless steel continuous hinges? They remain unfazed. Their ability to consistently perform, whether in chilling cold or intense heat, sets them apart. This consistency is indispensable for certain sectors.

Take, for instance, the aerospace industry or deep-sea exploration ventures. These fields demand equipment that can withstand diverse temperature gradients. And in these challenging conditions, stainless steel continuous hinges emerge as trusted allies.

Aesthetic Appeal

Beyond the realm of hardcore mechanics, lies the subtle world of aesthetics. And even here, stainless steel continuous hinges don’t disappoint. Their sleek, polished finish enhances the visual appeal of any machinery they’re part of. It’s not just about functionality; it’s about doing it with style.

For businesses that cater to premium clientele or sectors where visual appeal intertwines with functionality, these hinges add that touch of elegance, subtly underscoring their premium nature.

Low Maintenance

Maintenance can drain resources, both in terms of time and money. Herein lies another strength of stainless steel continuous hinges: their remarkably low maintenance demands. Their innate resistance to corrosion and temperature-induced wear means they stay functional longer, demanding fewer interventions.

Reduced wear and tear translate to longer intervals between replacements. Furthermore, their inherently smooth surface facilitates easy cleaning. This combination of features ensures that over time, industries benefit from considerable operational savings.

Versatility in Design

Stainless steel continuous hinges defy the conventional. Their name might hint at uniformity, but in practice, they champion versatility. Whether it’s adjusting the length for a specific machine or tweaking the pin size for a niche function, these hinges are all about customization.

This adaptability finds resonance in sectors ranging from automotive to cutting-edge robotics, showcasing that one size doesn’t necessarily fit all, and sometimes, it’s all about crafting the perfect fit.

Economical Over Time

The initial cost is just one part of the investment puzzle. True value emerges over time, and this is where stainless steel continuous hinges shine. While their initial procurement cost might be on the higher side, their long-term benefits, especially in terms of durability and reduced maintenance, paint a different picture.

When industries factor in the extended lifespan of these hinges and the associated cost savings from fewer replacements and minimal repairs, the economic advantage of opting for these hinges becomes crystal clear.

Environmental Impact

The green revolution is in full swing, and every component’s environmental impact is under the scanner. Stainless steel continuous hinges rise to this challenge with their recyclability. Post their operational lifecycle, they can be reincarnated, curbing the need for fresh resources.

This environmentally friendly trait not only conserves valuable resources but also aligns industries with global sustainability goals, fortifying their eco-conscious credentials.

Conclusion

From resisting environmental adversaries to championing sustainability, stainless steel continuous hinges are more than just mechanical components. They encapsulate the essence of modern-day industrial needs, seamlessly blending strength, durability, and adaptability.

You might also be interested: