First paragraph, cutting piano hinges is a specialized process that requires precision and expertise. In the industrial sector, these hinges are essential in various applications, and knowing how to cut them properly can impact their performance.

Cutting piano hinges requires careful measurement, marking, and using the right tools. The process generally includes measuring the hinge to the desired length, marking the cut line, clamping the hinge securely, and using a hacksaw or a metal cutting blade with a power saw to make the cut. Finally, filing the edges smooths out any roughness left from the cutting process.

Continue reading to learn the nuances of cutting piano hinges and how you can customize them for your specific industrial needs.

What are piano hinges?

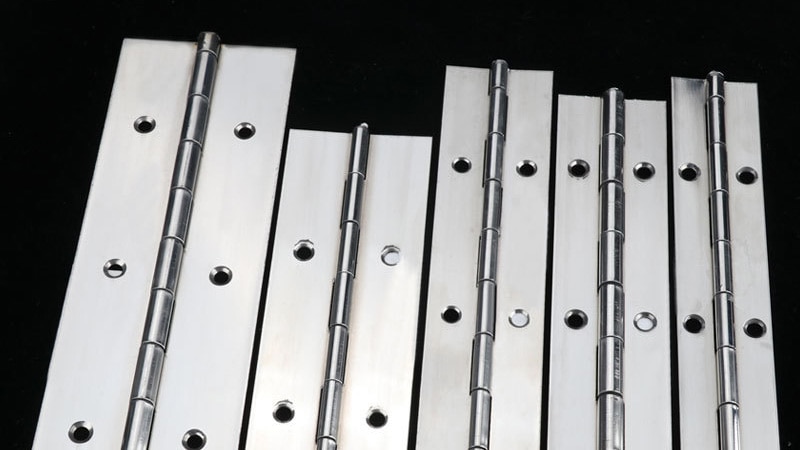

Piano hinges are continuous hinges used in various industrial applications. They are long, narrow, and provide a seamless connection between two parts. Being a crucial element in industries like automotive and aerospace, understanding their structure and function is essential.

When you know the details of what makes up a piano hinge, you can cut and customize it according to your specific industrial requirements. Its structure allows for flexibility and adaptability in different contexts.

How to cut piano hinges?

-

Measuring and Marking:

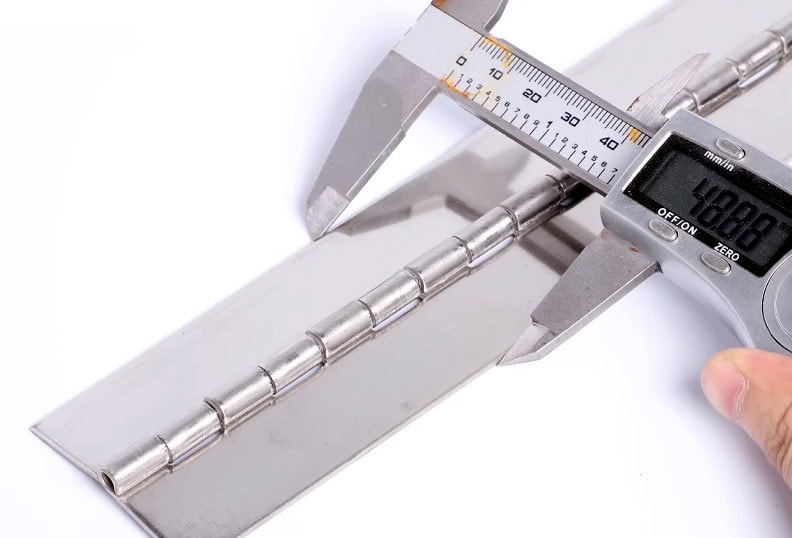

- Measure: Determine the length of the piano hinge needed for your particular application.

- Mark: Use a straightedge and a fine-pointed marker to mark the precise location where the hinge will be cut. The cut should be made in the gap between the knuckles, not through them.

-

Clamping:

- Secure the Hinge: Place the hinge on a sturdy work surface, like a workbench, and use clamps to hold it firmly in place. This ensures stability and accuracy while cutting.

-

Choosing the Right Tools:

- Hacksaw: A hacksaw with a fine-toothed blade designed for cutting metal can be used.

- Power Saw with Metal Cutting Blade: If available, a power saw equipped with a metal cutting blade offers faster and more efficient cutting.

-

Cutting:

- Align the Blade: Ensure the blade is aligned with the marked line.

- Apply Even Pressure: Begin cutting, applying steady and even pressure. Let the blade do the work, rather than forcing it through the metal.

- Check Alignment: Periodically check alignment to ensure you are following the marked line.

-

Finishing:

- File the Edges: Once the cut is complete, use a metal file to smooth any rough or sharp edges. This provides a professional finish and ensures the cut edge is safe to handle.

- Check for Alignment: Test the cut hinge in its intended application to ensure it fits properly.

-

Safety Considerations:

- Wear safety glasses to protect your eyes from metal shavings.

- Use gloves to protect your hands from sharp edges.

- Follow the safety guidelines provided with the tools you are using.

How do I ensure the quality of the cut?

Quality control in cutting piano hinges is paramount. Utilizing the proper tools, maintaining sharp blades, and following guidelines can all contribute to a high-quality cut.

Regular inspection and testing of the cut pieces are also essential to ensure that they meet the required industrial standards. Quality assurance leads to a reliable product that functions effectively in its intended application.

Can I ask the manufacturer to cut it for me?

It is indeed possible to ask manufacturers to cut piano hinges to your specifications. They have specialized machinery and expertise that can provide precise cuts.

However, understanding how it’s done helps in better communication with the manufacturer and ensures that the product is tailored exactly to your industrial needs.

Can I cut piano hinges of different materials?

Different materials require different cutting techniques. Whether it’s steel, brass, or aluminum, each material has specific properties that need to be considered.

Using the appropriate cutting method for the particular material ensures that the hinge retains its integrity and performs effectively in its intended industrial application.

Will the performance be affected after cutting the hinges?

Cutting the hinges must be done with care to ensure performance isn’t compromised. An incorrect cut can lead to alignment issues or reduced durability.

Proper cutting, following industrial standards, will maintain the performance and longevity of the piano hinges. Careful consideration of every step in the cutting process is vital.

What do I need to do with the piano hinges after cutting?

After cutting, piano hinges may require deburring, polishing, and treatment for preventing corrosion, especially in industrial applications where they are subjected to harsh conditions.

These post-cutting processes are essential in preparing the hinges for their specific industrial applications and ensuring they function as intended over their lifespan.

How do you customize a piano hinge?

Customizing a piano hinge involves understanding its application, choosing the right material, cutting it to the desired length, and applying specific finishes or treatments.

This customization allows for a perfect fit in various industrial scenarios and ensures that the hinge performs to the highest standards. Tailoring the hinge to the exact requirements is a crucial aspect of industrial manufacturing.

Conclusion

Cutting and customizing piano hinges is a specialized task that requires attention to detail, quality assurance, and understanding of the materials and processes involved. The guidelines provided in this post will enable you to approach this task with confidence and professionalism in the industrial sector.

Need to customize your piano hinges? Click here to go to the featured page to submit your request.

You might also be interested: