In the realm of industrial manufacturing, the choice of materials for components is crucial. Every material has its own set of properties that can vastly impact the performance and longevity of a product. One such material, often used for hinges in this sector, is brass.

Brass hinges stand out due to their unique combination of aesthetic appeal, strength, and resistance.

Though seemingly simple in function, the properties of brass bring about numerous advantages that can be game-changers in the world of industrial machinery and applications. Let’s delve deeper into the specific features of brass hinges and understand their significance.

Durability and Strength

Brass, an alloy of copper and zinc, possesses inherent strength. This robustness ensures that hinges made from brass can withstand the stresses of regular industrial use.

Moreover, they resist wear and tear, ensuring a longer life span. Such durability proves vital in industries where frequent hinge replacements can be costly and time-consuming.

Corrosion Resistance

One of the standout features of brass is its excellent resistance to corrosion. When used in hinges, this property becomes crucial, especially in environments where moisture and chemical exposure are common.

As a result, brass hinges remain functional and maintain their appearance even in challenging industrial settings, reducing the need for frequent replacements or maintenance.

Thermal Conductivity

Brass has a moderate level of thermal conductivity, meaning it can quickly dissipate heat. In industrial applications where temperature regulation is crucial, brass hinges can be a strategic choice.

Such a feature ensures that even in high-temperature environments, these hinges remain efficient, thereby safeguarding the machinery or containers they are part of.

Machinability

Brass is known for its excellent machinability. This property ensures that manufacturing brass hinges is relatively easier, allowing for precise designs and finishes.

With easier machining comes cost-effectiveness in production, making brass hinges a viable choice for industrial applications where budget constraints might be a factor.

Aesthetic Appeal

While industrial manufacturing primarily focuses on function, aesthetics can still play a part, especially in consumer-facing machinery. Brass hinges, with their golden sheen, can enhance the appearance of a product.

Their natural luster combined with the ability to take on various finishes ensures that even in an industrial context, aesthetics are not compromised.

Non-Magnetic Property

In industries where magnetism can interfere with operations, the non-magnetic nature of brass becomes a vital feature. Brass hinges ensure that no unwanted magnetic fields are introduced into the system.

This property becomes especially crucial in electronics manufacturing or any sector where magnetic interference can hamper the performance of devices.

Flexibility in Design

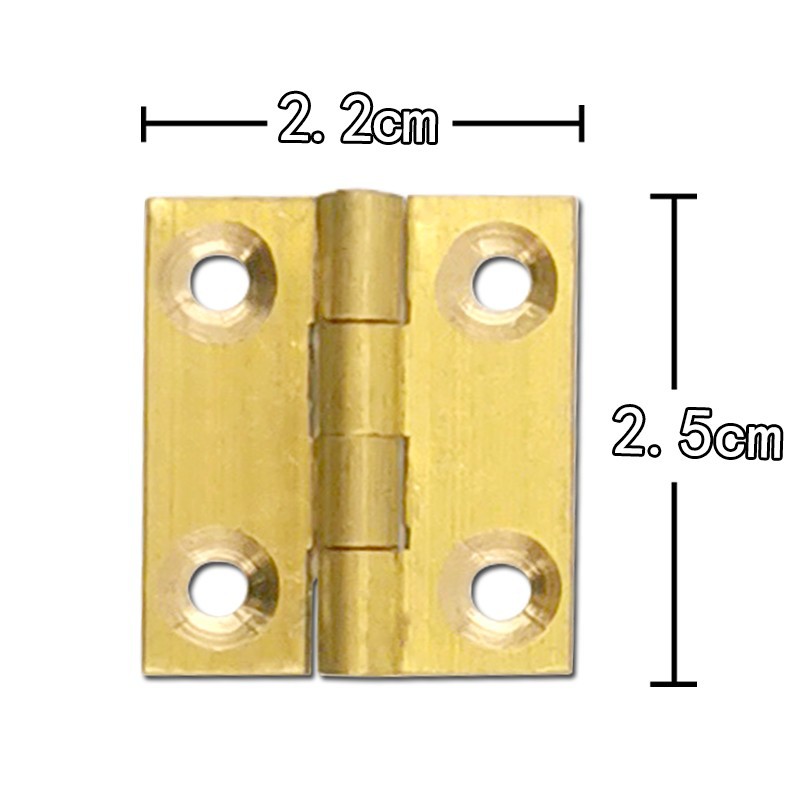

Owing to brass’s malleability, hinges made from it can be crafted into various shapes and sizes, catering to specific industrial needs.

This flexibility in design ensures that brass hinges can be customized to fit into diverse applications, making them a versatile choice in the world of industrial manufacturing.

Environmental Benefits

Brass is recyclable, which means that at the end of their lifespan, brass hinges can be melted down and reused. Such a feature reduces waste, making them an environmentally-friendly choice.

In industries keen on sustainability and reducing their carbon footprint, opting for brass hinges can be a step in the right direction.

Conclusion

Brass hinges, with their myriad of features, are not just functional pivots in the world of industrial manufacturing. They embody strength, durability, aesthetics, and versatility. As industries evolve and adapt to new challenges, these brass-based components, deeply rooted in tradition, continue to shine, proving their mettle time and again.

You might also be interested: