Have you ever heard the term “marine piano hinge” and wondered what it was? This unique hinge has its own set of applications, especially within the industrial manufacturing sector. While some may instantly think of furniture or home renovations upon hearing the word “hinge,” this isn’t where the marine piano hinge shines.

Marine piano hinges are long, continuous hinges often used in marine and industrial applications because of their durability and resistance to corrosion.

Understanding marine piano hinges better can offer significant advantages to those in the industrial manufacturing realm. Let’s delve into the specifics.

Why “Piano” in Marine Piano Hinge?

The term “piano” in the marine piano hinge derives from its origin. Originally, these types of hinges were used on piano lids because of their ability to spread the load across the entire length of the lid.

However, over time, the functionality of these hinges was recognized beyond just musical instruments. Their strength and ability to distribute weight made them ideal for various applications, especially in environments exposed to water and salty air.

Corrosion Resistance: Why Is It Important?

One of the most critical features of marine piano hinges is their resistance to corrosion. But why?

Corrosion can weaken structures and components, leading to potential failures in crucial applications. Marine environments, with salt and water, are particularly challenging due to the high potential for oxidization and damage.

Thus, using corrosion-resistant materials like marine piano hinges ensures longevity and reduces maintenance requirements. It’s a matter of safety and reliability, especially in industrial manufacturing.

Material Choices: Stainless Steel or Brass?

Marine piano hinges are typically made from either stainless steel or brass. But what’s the difference?

Stainless steel hinges offer strength and resilience, making them ideal for heavy-duty applications. Their chromium content offers protection against corrosion, especially in salty environments.

Brass, on the other hand, has natural corrosion-resistant properties. While it may not be as strong as stainless steel, it is often chosen for aesthetic reasons or when the application doesn’t demand high strength.

Pin Design: Removable or Fixed?

When selecting a marine piano hinge, one important consideration is the pin design.

Removable pins offer flexibility, allowing users to detach the joined elements when necessary. This can be particularly beneficial in industrial settings where components need periodic cleaning or maintenance.

Fixed pins provide more security, ensuring that the hinge remains intact. For applications where tampering or unintended detachment can pose risks, fixed pins are the go-to choice.

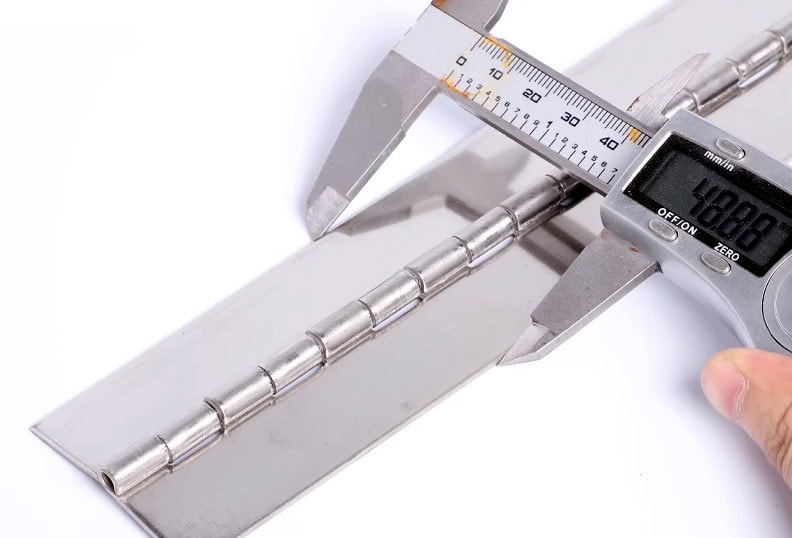

Length and Size: Does It Matter?

The length and size of marine piano hinges can vary greatly based on the specific application.

Longer hinges distribute weight across a larger area, ensuring stability, especially in larger installations. Meanwhile, the width or size of the hinge impacts its load-bearing capacity.

Selecting the right length and size is crucial to ensure optimal functionality and durability. It’s not a one-size-fits-all solution, and understanding the requirements of the specific industrial application is essential.

Mounting Techniques: Weld On or Screw On?

How marine piano hinges are mounted plays a significant role in their efficacy.

Weld-on hinges offer a permanent solution, ensuring that the hinge remains firmly in place. This method is ideal for heavy-duty applications where movement and weight might challenge the hinge’s integrity.

Screw-on hinges, conversely, provide flexibility. They’re easier to install and replace, making them a preferred choice for applications that might need frequent hinge replacements or adjustments.

Industrial Uses: Where Are They Found?

Beyond the marine environment, where else might you find marine piano hinges?

They are extensively used in the manufacturing of heavy machinery, transport vehicles, and even aerospace applications. The consistent durability and adaptability of these hinges make them ideal for situations demanding resilience and reliability.

Conclusion

Marine piano hinges are more than just components for boats or ships. Their strength, corrosion resistance, and versatility make them an essential element in various industrial manufacturing applications. From material choices to mounting techniques, understanding these hinges can make a significant difference in the efficacy and longevity of the final product.

You might also be interested: