If you’ve ever found yourself pondering the intricacies of aircraft design, then you might have stumbled upon the topic of aircraft hinges. It’s one of those critical but often overlooked elements of aircraft manufacturing. These small but essential components play a pivotal role in ensuring the safety and functionality of aircraft.

So, what exactly are aircraft hinges? In simple terms, they are movable joints that connect and allow relative rotation of various parts of an aircraft. They might not be the most glamorous part of an airplane, but without them, flying would be far more challenging.

As we continue, we’ll delve deeper into the fascinating world of aircraft hinges, exploring their types, applications, materials used in manufacturing, and much more. So sit back, fasten your seatbelt, and prepare for takeoff into the world of aircraft engineering.

What is the Purpose of Aircraft Hinges?

Aircraft hinges are designed to provide a flexible point of connection between different parts of an aircraft. They allow relative movement while ensuring that those parts remain firmly connected. In essence, hinges enable crucial components of an aircraft to function smoothly, ensuring optimum performance and safety.

A clear example of this is the aircraft door, which hinges allow it to swing open and close. Similarly, control surfaces such as ailerons, elevators, and rudders also use hinges to facilitate their movements. Without these, it would be impossible to control the aircraft’s direction, altitude, and speed.

What are the Different Types of Aircraft Hinges?

Diverse requirements of aircraft components have led to the development of different types of hinges. Some of the most commonly used include piano hinges, concealed hinges, and butt hinges, each with its unique characteristics and applications.

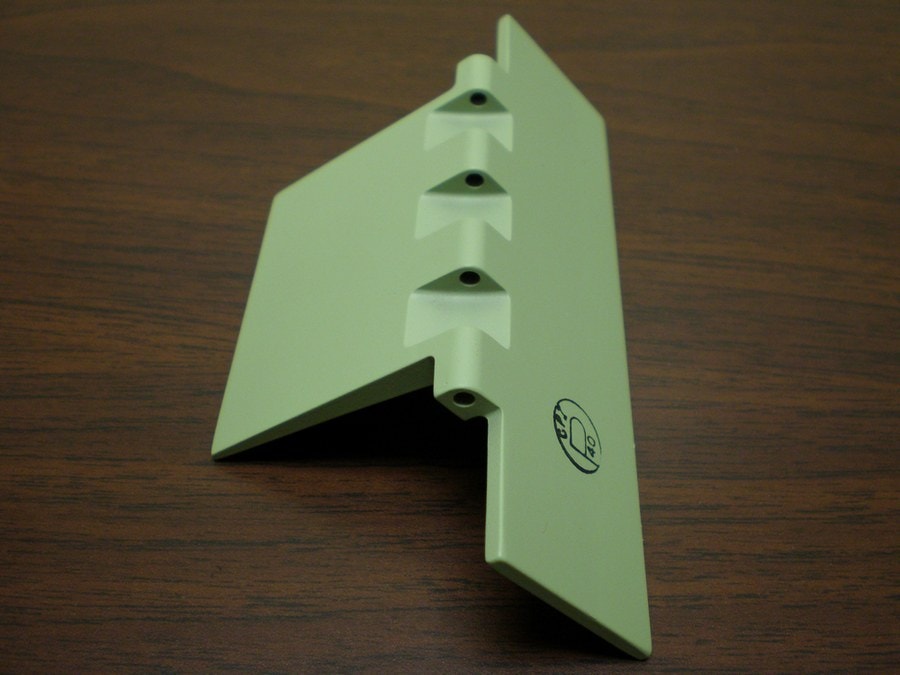

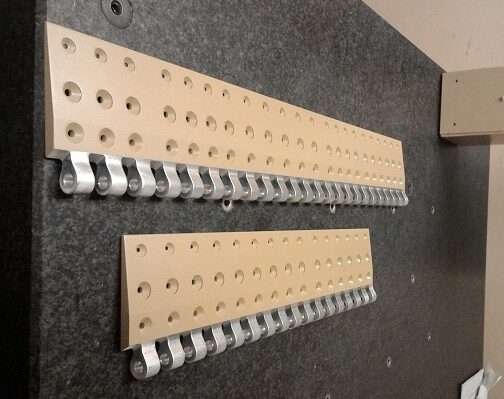

Piano hinges, often called continuous hinges, are long and narrow, running the full length of the joined panels. They distribute the load evenly across the entire length, making them particularly suited for heavy doors and panels. On the other hand, concealed hinges are hidden when the door is closed, offering an aesthetically pleasing appearance without compromising the hinge’s functional role. Butt hinges are perhaps the most common hinge type, and you can find them on most aircraft cabin doors.

How are Aircraft Hinges Manufactured?

Manufacturing aircraft hinges requires precise engineering and the use of high-quality materials. The process often involves cutting, bending, and forming metal into the desired hinge shape, which is then heat-treated to enhance its strength and durability.

In some instances, aircraft hinges undergo a process called anodizing. This creates a protective oxide layer on the metal’s surface, enhancing its resistance to corrosion. Given the crucial role hinges play and the demanding environment they operate in, quality control in manufacturing is vital.

What Materials are Used to Make Aircraft Hinges?

When it comes to materials for making aircraft hinges, the key considerations include strength, weight, and resistance to environmental factors like corrosion. Aluminum, stainless steel, and titanium are the most commonly used materials.

Aluminum is lightweight and offers a good balance of strength and corrosion resistance, making it suitable for many aircraft applications. Stainless steel is more robust and resistant to heat, but it is also heavier. Finally, titanium offers the best of both worlds, with high strength, low weight, and excellent corrosion resistance, albeit at a higher cost.

Are there Standards for Aircraft Hinges?

Just like any other component of an aircraft, hinges are subject to stringent standards to ensure their safety and effectiveness. These standards govern everything from design and materials to manufacturing processes, testing, and maintenance.

Standards such as those established by the Aerospace Industries Association (AIA) and the American National Standards Institute (ANSI) are commonly used in the industry. Compliance with these standards ensures that the hinges will perform their intended function reliably and safely under various operating conditions.

How are Aircraft Hinges Maintained?

Maintenance of aircraft hinges is crucial to ensure their continued effectiveness and the overall safety of the aircraft. This typically involves regular inspections for signs of wear and tear, corrosion, or damage.

If a problem is detected, depending on its severity, the hinge may be repaired or replaced. Lubrication is another crucial part of aircraft hinge maintenance. Regular lubrication helps to reduce friction, prevent wear, and extend the life of the hinge.

Conclusion

In conclusion, aircraft hinges may not be the most recognized part of an aircraft, but their role in ensuring smooth and safe operations is invaluable. Whether it’s the materials used, the manufacturing process, or the standards adhered to, every aspect of their design is optimized for safety and efficiency. So, the next time you board a plane, spare a thought for these unsung heroes of aviation engineering.

You might also be interested: