Have you ever wondered what type of hinges are used in the world of industrial manufacturing to support the most weight? This question often pops up in the minds of people when they see heavy machinery in operation, swinging or moving with seemingly minimal support. It’s a marvel of modern engineering that we can design systems that not only handle colossal weights but do so efficiently and safely.

The answer lies in the different types of hinges used in this sector. While many variables determine a hinge’s load-bearing capacity, including the material and design, some types are specifically built for heavyweight applications.

Now that we have established that, let’s delve into the various heavy-duty hinge types utilized in industrial manufacturing. Get ready to explore the engineering genius behind these little marvels of strength!

Are Piano Hinges Ideal for Heavy Load?

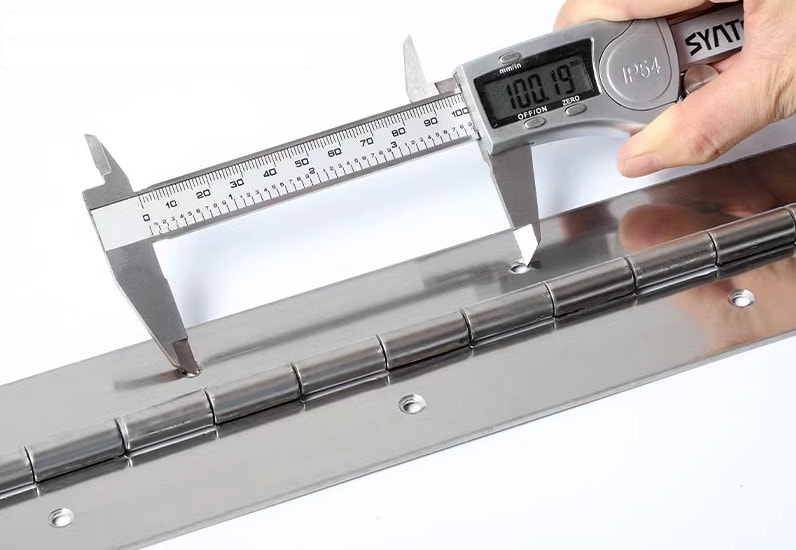

When we think about high weight-bearing hinges, piano hinges, also known as continuous hinges, often come to mind. This is because the hinge runs the entire length of the door or panel, distributing the weight evenly and reducing the stress on individual points.

However, in industrial manufacturing, these are not the most commonly used hinges. The length of piano hinges can limit their applications. Additionally, while these hinges are capable of carrying significant weight, there are other types that handle much more load due to their specific design and material choices.

What Role Does a Butt Hinge Play?

Butt hinges are one of the simplest and most common types of hinges, yet they can pack quite a punch when it comes to supporting weight. They’re named so because they’re ‘butted’ against the door and the frame.

In heavy machinery, butt hinges can be constructed from solid, durable metals such as stainless steel or brass. While they may not be as specialized as other types, their simplicity, robustness, and ease of installation make them a favorite in many industrial manufacturing applications.

How Do Heavy-Duty Gate Hinges Work?

Heavy-duty gate hinges are often employed in industrial settings. These hinges are designed to support massive gates, doors, and entrances, which often weigh several tons.

In the industrial manufacturing sector, these hinges are usually made from hardened steel and often feature additional support mechanisms, such as a grease fitting for smooth operation and to extend the hinge’s lifespan. Their robust design allows them to handle tremendous weight, and their strength is simply unmatched in the hinge world.

Are Pivot Hinges Suitable for High Weight?

Pivot hinges, as the name suggests, allow a door or panel to pivot rather than swing. The weight is concentrated at the bottom, and the top hinge is mainly used for guiding the motion.

Pivot hinges in industrial applications are designed for heavy duty use and made from hardened steel or sometimes even titanium. Because the weight is concentrated at the bottom, these hinges are ideal for very heavy doors or panels where a traditional side-mounted hinge could fail under the load.

Does the Design of European Hinges Support Weight?

European hinges, also known as concealed hinges, are not commonly associated with heavy-duty applications. This is because they are usually used in furniture applications for their aesthetic appeal.

However, industrial-grade European hinges do exist and are made from high-strength materials like stainless steel or brass. While they may not support the heaviest loads compared to other types of hinges, their concealed design offers unique benefits in some industrial applications.

How Do Hinge Materials Impact Weight Capacity?

The material from which a hinge is made significantly impacts its weight-bearing capacity. Common materials include stainless steel, brass, and sometimes even hardened plastic for specific applications.

For heavy-duty industrial applications, the material choice is usually some form of hardened steel. This material is not only extremely durable but also resistant to wear, making it perfect for high-stress environments found in the industrial manufacturing sector.

Conclusion

In the world of industrial manufacturing, the hinges used are as varied as they are ingenious. From butt hinges to heavy-duty gate hinges, the choice of hinge depends on the specific application and the weight it is expected to bear. While material choice is crucial, the design of the hinge also plays a critical role in determining its load-bearing capacity. The heavy-duty hinges used in industrial manufacturing truly are marvels of modern engineering.

You might also be interested: