In our journey to understand the nuances of industrial manufacturing, we’ve all encountered terms that sound foreign and complicated. Ball bearing hinges and washers, two components found ubiquitously in this sector, often fall into this category. It’s not uncommon for me to hear questions about their purpose, how they differ, or even if they are interchangeable.

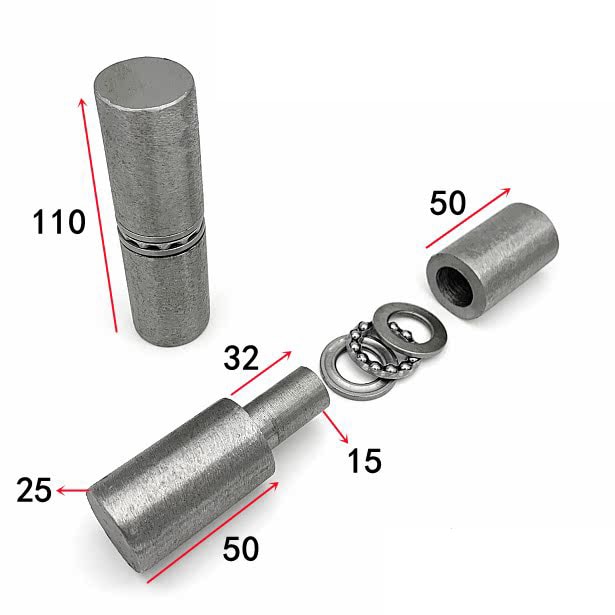

These components, while both pivotal in their function, couldn’t be more different. Washers, flat disks with a hole in the middle, are used to distribute load, while ball bearing hinges, typically consisting of two leaf plates with circular bearings in between, are used to facilitate rotational movement. Their unique characteristics and functionalities offer fascinating insights into the vast world of industrial manufacturing.

Don’t worry if these terms still sound like Martian to you! I promise, by the end of this blog, we’ll have all your questions answered.

What are washers, and why are they important in industrial manufacturing?

Washers, thin plates with holes, are akin to the unsung heroes of the industrial world. They perform a multitude of functions, one of the most critical being load distribution. When a screw or a bolt is tightened, the force exerted can be immense. A washer helps distribute this force over a larger area, preventing damage to the surface material and maintaining the integrity of the assembly.

Furthermore, washers provide a smooth and flat surface for the fastener to move against. This reduces friction, increases the lifespan of the assembly, and maintains the fastener’s position over time. They may be small and simple, but without them, the durability and effectiveness of industrial applications would be significantly compromised.

How are ball bearing hinges used in industrial applications?

Shifting our focus, let’s explore the world of ball bearing hinges. Hinges, as we know, enable rotational motion. Ball bearing hinges take this a step further – they incorporate bearings between their leaf plates to reduce friction and ensure smoother movement, even under heavy loads. This makes them a highly desirable component in the realm of industrial manufacturing.

The enhanced durability and fluid movement of these hinges mean they are often used in high-frequency and heavy-duty applications. They can be found in machinery, industrial doors, and even heavy equipment. Their sturdy build and ability to handle immense weight and constant use without wear make them an industrial favorite.

Understanding the differences: material and structure

A key differentiator between washers and ball bearing hinges is the material they’re made of. Washers are typically made of metal or plastic, selected based on the demands of the application – be it electrical insulation, load distribution, or corrosion resistance.

On the other hand, ball bearing hinges are primarily made of metal, often stainless steel or brass, to handle the strain of constant rotational movement and heavy loads. The choice of material not only defines their durability but also the type of applications they’re suitable for.

Differentiating functionalities: load distribution vs. rotational movement

As mentioned earlier, washers excel in load distribution, and ball bearing hinges facilitate smooth rotational movement. This distinction in functionality determines their specific roles within an industrial setting.

Washers are used wherever there’s a need to protect the surface from the pressure of fasteners or to keep those fasteners in place. Their function, though rudimentary, is vital in maintaining the efficiency of many industrial applications.

On the contrary, ball bearing hinges are used where smooth and effortless motion is required, such as heavy doors and various types of machinery. The bearings help reduce friction, allowing the hinge to perform consistently even under high load and frequency of use.

Performance under pressure

The manner in which these components perform under pressure also sets them apart. Washers, due to their flat and thin structure, can endure high amounts of pressure, distribute it evenly, and prevent surface damage. Their design enables them to perform their function without significant wear and tear.

Ball bearing hinges, in contrast, thrive under heavy loads but in a different way. The ball bearings within these hinges decrease friction and allow the hinge to move freely, making them ideal for applications with heavy usage or high-frequency operations.

Final thoughts on washers and ball bearing hinges

I hope this discussion helped clarify the fundamental differences between washers and ball bearing hinges. It’s clear that despite their differing structures and functionalities, they both play pivotal roles in the success of many industrial applications. They are the unsung heroes, quietly ensuring the smooth operation of our modern industrial world.

Don’t let their size fool you! The impact of these small components is huge. They ensure our machines run smoothly, our products are built correctly, and our industrial world continues to rotate, quite literally in the case of the ball bearing hinges!

You might also be interested: