Stepped convex door hinges play a crucial role in the industrial sector, providing seamless movement, durability, and aesthetic appeal to doors. In this article, we delve into the details of stepped convex door hinges, exploring their installation process, different types available, advantages, disadvantages, common applications, maintenance tips, tips for selecting the right size and material, comparison with other hinge types, troubleshooting common issues, and finally, design options and finishes.

What are stepped convex door hinges?

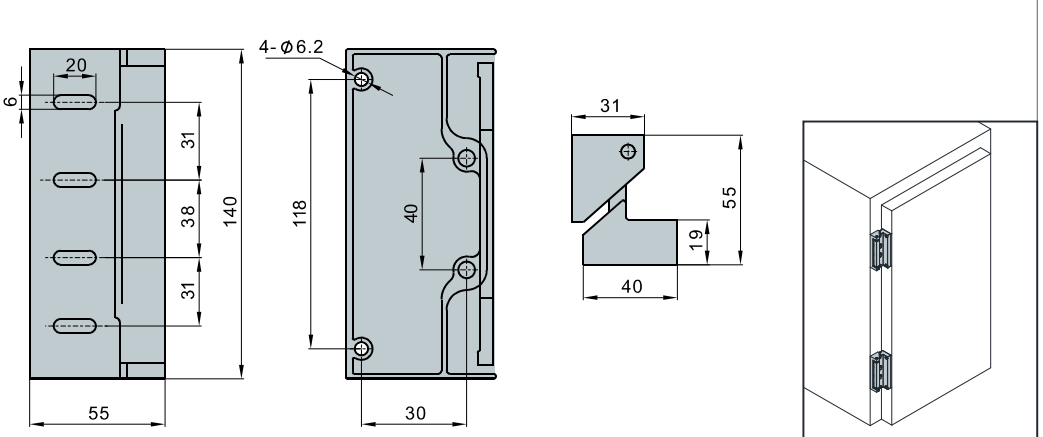

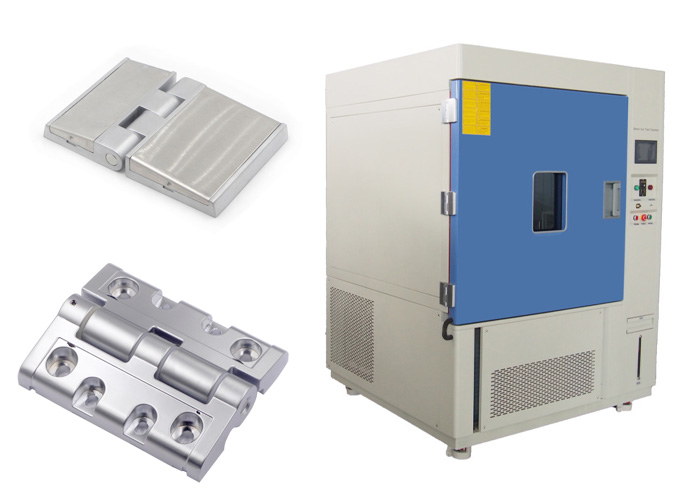

Stepped convex door hinges are precision-engineered hardware components designed to facilitate smooth door movement. With their unique stepped convex design, these hinges create a pivoting point that distributes weight evenly, minimizing stress on the hinge and ensuring optimal functionality. The well-engineered structure enhances the weight-bearing capacity of the hinge, making it ideal for heavy-duty industrial applications.

When compared to traditional hinges, stepped convex door hinges provide enhanced durability and longevity. Their robust construction and design allow them to withstand the harsh conditions often found in industrial environments. Additionally, they offer smooth and noiseless operation, ensuring hassle-free movement of doors and reducing the risk of damage or wear over time.

How to install the hinges?

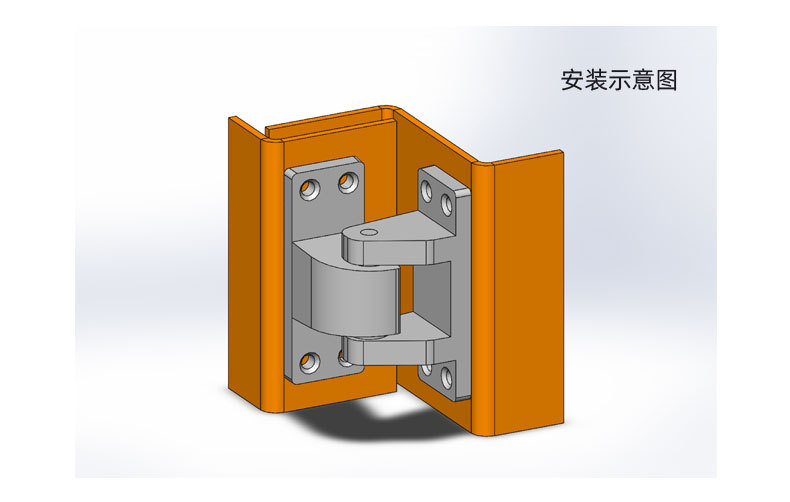

The installation of the convex door hinges requires meticulous attention to detail to ensure proper functionality and longevity. Begin by aligning the hinge leaf plates with the door and frame, ensuring they are perfectly flush. It is crucial to accurately mark the placement of the hinges to avoid misalignment. Once aligned, secure the hinge to the door and frame using appropriate screws or fasteners, ensuring a tight fit.

During installation, it is essential to follow the manufacturer’s guidelines and recommendations. This includes selecting the correct size and weight-bearing capacity suitable for the door and application at hand. It is also advisable to consult with professionals experienced in hinge installation to ensure precise alignment and operation.

After installation, perform a thorough inspection to ensure the hinges are securely attached and aligned correctly. Conducting regular maintenance checks and promptly addressing any signs of misalignment or wear will contribute to the long-term functionality and reliability of the convex hinges.

Different types of stepped convex door hinge

They come in various types, each designed to meet specific industrial requirements. Industrial professionals can choose from heavy-duty hinges, continuous hinges, or concealed hinges, based on the specific application and desired aesthetics.

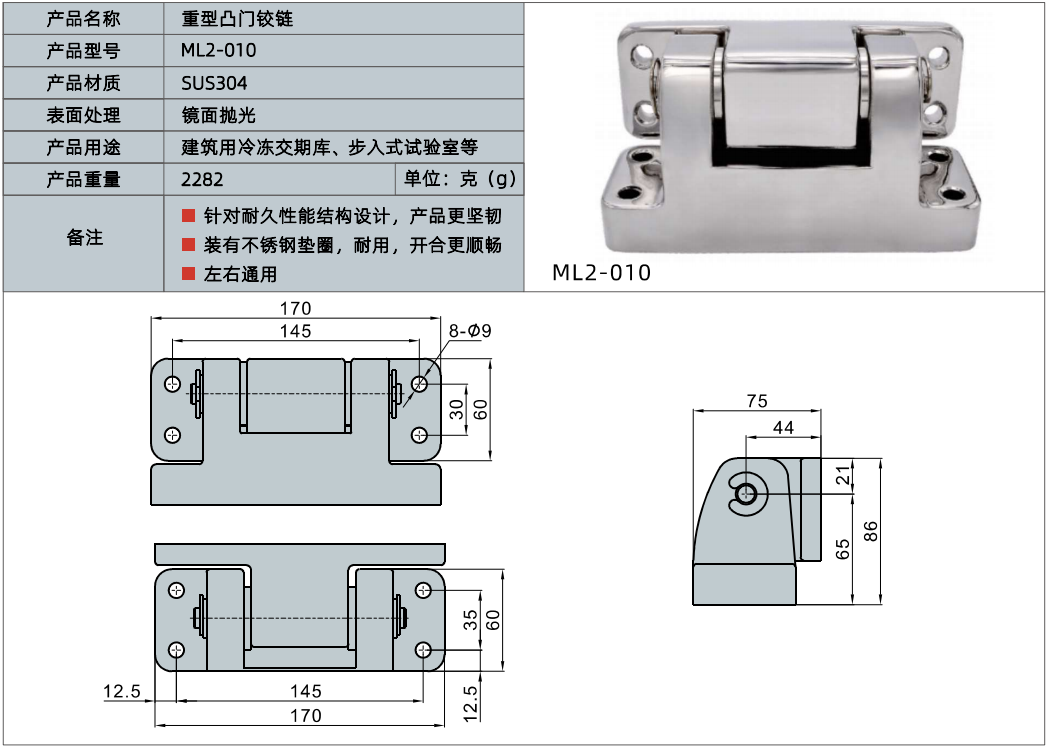

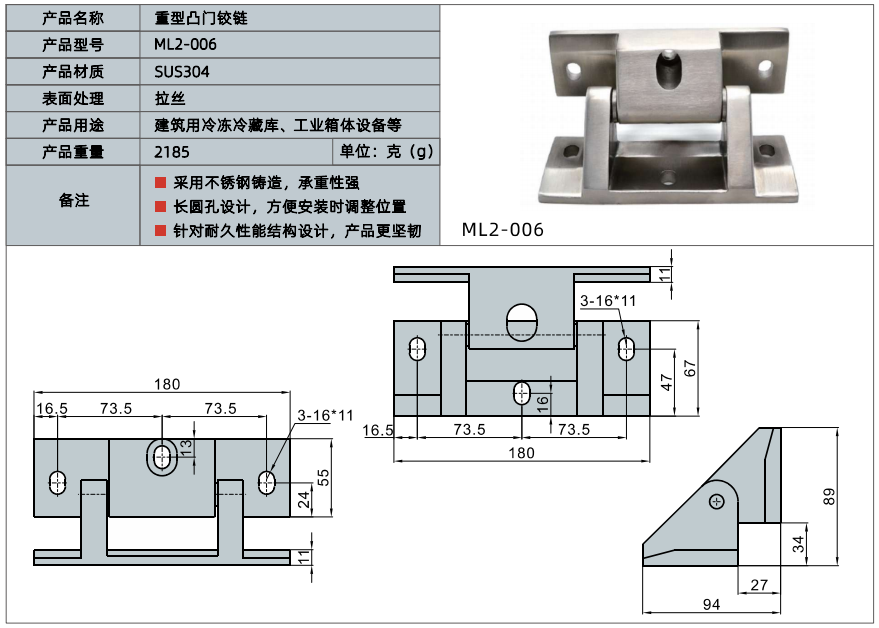

Heavy-duty hinges are specifically engineered to withstand substantial weight loads and intense usage, making them suitable for industrial machinery doors or large gates. Continuous hinges, on the other hand, are designed for applications that require full-length door support, such as large industrial doors or gates. These hinges provide exceptional stability and eliminate the need for multiple smaller hinges.

Concealed hinges offer a sleek and seamless appearance, as they are hidden within the door and frame. They are a popular choice for industrial cabinets, secure storage areas, and equipment enclosures, providing both functionality and aesthetic appeal.

Advantages and disadvantages of using stepped convex door hinge

Stepped convex door hinges offer several advantages that make them a preferred choice for industrial applications. Their stepped convex design enhances weight-bearing capacity, ensuring the smooth movement of heavy doors without compromising stability. The hinges also reduce stress on the door and frame, minimizing the risk of warping or damage over time.

In addition to their functionality, stepped convex door hinges provide durability and longevity. Constructed from high-quality materials such as stainless steel or brass, they offer excellent resistance to corrosion and wear, making them ideal for industrial environments. The robust nature of these hinges enhances security, providing a reliable barrier against unauthorized access.

Despite their numerous advantages, it is important to consider potential disadvantages when using the hinges. The complexity of installation may require professional assistance, particularly for intricate or heavy-duty applications. Additionally, periodic maintenance checks and lubrication are necessary to maintain optimal performance and prevent issues such as friction or misalignment.

Common applications and uses of hinges

Stepped convex door hinges find wide-ranging applications across various industrial sectors. They are commonly used for heavy machinery doors, equipment enclosures, industrial cabinets, secure storage areas, and access panels. Their ability to support heavy loads and provide smooth, reliable movement makes them indispensable in industrial settings.

They are also suitable for applications that require frequent usage, ensuring longevity and continuous performance. Their sturdy construction and resistance to wear and tear make them an ideal choice for environments where durability is paramount, such as factories, warehouses, and industrial facilities.

How to maintain and care for stepped convex door hinges

Regular maintenance is essential to ensure the longevity and optimal performance of stepped convex door hinges. Periodically inspect the hinges for any signs of wear, misalignment, or damage. Lubrication is crucial to reduce friction and prevent rust or corrosion. Apply a high-quality lubricant specifically designed for hinges, ensuring all moving parts are adequately coated.

During maintenance checks, also examine the mounting screws to ensure they are tight and secure. Loose screws can lead to misalignment and compromised functionality. If any issues are detected during inspection, address them promptly to prevent further damage or potential safety hazards.

Tips for choosing the right size and material for door hinges

Selecting the correct size and material for stepped convex door hinges is vital to ensure optimal performance and longevity. Consider factors such as the weight of the door, frequency of use, and the environmental conditions in which the hinges will be installed.

Consult the manufacturer’s guidelines and specifications to determine the appropriate weight-bearing capacity required for the application. Choosing hinges that exceed the door’s weight can help enhance durability and prevent premature wear or failure.

In terms of materials, stainless steel or brass hinges are popular choices due to their excellent corrosion resistance and durability. These materials ensure longevity, even in challenging industrial environments where exposure to moisture, chemicals, or extreme temperatures is a concern.

Comparing convex door hinges with other types of hinges

While stepped convex door hinges offer numerous advantages, it is important to compare them with other hinge types to determine the most suitable option for specific applications. Butt hinges, pivot hinges, and continuous hinges are some of the alternatives commonly used in industrial settings.

Butt hinges are traditional hinges suitable for doors that require a wide range of motion. They offer stability and ease of installation but may not withstand heavy loads like stepped convex door hinges.

Pivot hinges provide flexibility in terms of door swings, making them suitable for applications with unique design requirements. However, they may not provide the same weight-bearing capacity as stepped convex door hinges.

Continuous hinges, also known as piano hinges, provide full-length door support, eliminating the need for multiple hinges. They offer exceptional stability and can withstand heavy loads, making them suitable for large industrial doors or gates. However, they may lack the stepped convex design,

which provides added strength and reduces stress on the hinge.

Troubleshooting common issues with convex door hinges

Despite their durability, stepped convex door hinges may encounter occasional issues that affect their functionality. Common problems include misalignment, squeaking, or excessive friction during door movement. To troubleshoot these issues, begin by examining the hinge alignment and adjusting it if necessary. Lubricate the hinges with a suitable lubricant to minimize friction and noise. If the problems persist, it may be necessary to replace worn-out or damaged hinge components to restore optimal functionality.

Regular inspections and maintenance checks can help detect and address these issues promptly, ensuring the continued performance of the hinges and preventing further damage.

Exploring design options and finishes for convex door hinges

Stepped convex door hinges offer versatility not only in functionality but also in design. They are available in a range of design options and finishes to complement various industrial aesthetics.

Design options for stepped convex door hinges include different shapes and sizes, allowing customization to meet specific design requirements. Whether it’s a sleek and modern look or a more traditional and rustic appearance, there are hinge designs available to suit every industrial setting.

In addition to design options, stepped convex door hinges also come in a variety of finishes. Polished finishes provide a classic and elegant look, while brushed finishes offer a more contemporary and industrial appeal. Powder-coated finishes provide durability and corrosion resistance, making them suitable for harsh industrial environments.

The choice of design and finish for stepped convex door hinges allows industry professionals to seamlessly integrate them into the overall design scheme. They can be selected to match existing hardware or create a focal point that adds aesthetic value to the industrial space.

Conclusion

Stepped convex door hinges are essential components in the industrial sector, offering enhanced functionality, durability, and aesthetic appeal. By understanding their installation process, different types available, advantages, disadvantages, common applications, maintenance tips, tips for selecting the right size and material, comparison with other hinge types, troubleshooting common issues, and design options, industrial professionals can make informed decisions when incorporating these hinges into their applications.

The versatility of stepped convex door hinges ensures they can withstand heavy loads, provide smooth operation, and offer long-lasting performance in various industrial environments. Proper installation, regular maintenance, and the selection of the right size, material, and finish contribute to their longevity and optimal functionality.

With their ability to seamlessly blend functionality and design, stepped convex door hinges provide the perfect solution for industrial spaces seeking reliability, durability, and aesthetic appeal in their door systems.