Weld-On Hinges are an essential component in various industrial applications, offering a secure and reliable connection between two surfaces. In this article, we will delve into the world of Weld-On Hinges, discussing their characteristics, outdoor applications, benefits, and key considerations for selecting the right hinge for your specific needs.

What are Weld-On Hinges?

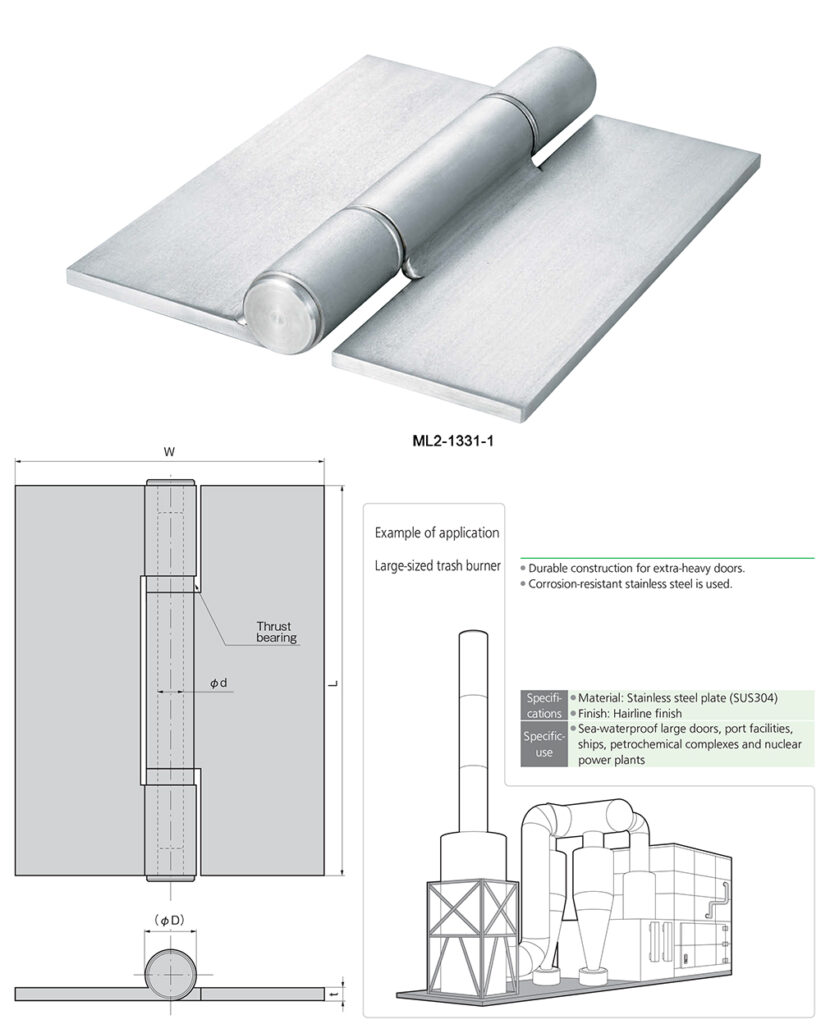

Weld-On Hinges, as the name suggests, are hinges that are attached to surfaces through welding. These hinges provide a permanent and robust connection, ensuring stability and durability in industrial environments. Unlike traditional hinges that may rely on screws or bolts, Weld-On Hinges offer seamless integration with the surface, eliminating the need for additional fasteners.

These hinges are generally produced in stainless steel or iron and differ from marine hatch hinges in the way they are mounted. marine hatch hinges are mainly used in seawater environments and are screw mounted for better maintenance and convenience.

What are the characteristics of Weld-On Hinges?

Weld-On Hinges possess several key characteristics that make them highly desirable in industrial applications. Firstly, their welded attachment provides exceptional strength and stability, making them suitable for heavy-duty applications. Secondly, Weld-On Hinges are known for their durability, capable of withstanding harsh conditions, including extreme temperatures, vibrations, and frequent use. Additionally, these hinges offer a compact and streamlined design, optimizing space utilization.

Why are Weld-On Hinges often used outdoors?

Weld-On Hinges find extensive use in outdoor environments due to their ability to withstand the elements and challenging conditions. These hinges are typically constructed from corrosion-resistant materials such as stainless steel or zinc-plated steel, making them highly resistant to rust, moisture, and UV exposure. Whether it’s in marine, construction, or agricultural settings, Weld-On Hinges provide reliable performance and longevity, ensuring smooth operation even in outdoor applications.

What are the benefits of using Weld-On Hinges?

The utilization of Weld-On Hinges offers numerous benefits in industrial settings. Firstly, their welded attachment provides a secure and tamper-proof connection, minimizing the risk of accidental disassembly or unauthorized access. Secondly, these hinges offer enhanced load-bearing capacity, allowing for the smooth operation of heavy doors, gates, or panels. Moreover, Weld-On Hinges are low-maintenance, requiring minimal upkeep over their lifespan.

How do I choose Weld-On Hinges?

When selecting Weld-On Hinges for your specific application, several factors should be considered. Firstly, determine the load capacity requirements to ensure the hinge can adequately support the weight of the door or panel. Secondly, consider the environmental conditions, such as exposure to moisture, chemicals, or extreme temperatures, and choose a hinge with the appropriate corrosion resistance properties. Additionally, assess the desired range of motion, including the required degree of rotation or pivot angle. Lastly, consult with industry experts or suppliers to ensure the hinge specifications align with your application’s unique needs.

Conclusion

Weld-On Hinges provide a reliable and durable solution for industrial applications. Offering characteristics such as strength, stability, and resistance to harsh environmental conditions. Whether used outdoors or in demanding environments, these hinges play a vital role in ensuring the smooth operation of doors, gates, and panels. By understanding the characteristics, outdoor applications, benefits, and key selection criteria, industry professionals can make informed decisions when choosing Weld-On Hinges for their specific requirements.