Heavy duty exterior hinges play a vital role in industrial applications, providing reliable and secure door functionality in demanding environments. In this article, we will explore the various types of heavy duty exterior hinges available and their significance in industrial settings.

Butt Hinges

Butt hinges are a commonly used hinge type known for their durability and strength. These hinges consist of two leaves joined by a pin, allowing for smooth rotational movement. Butt hinges for heavy duty exterior applications are typically made from robust materials such as stainless steel or brass, ensuring resistance to harsh weather conditions and frequent use. They are widely employed in industrial settings where sturdy and reliable door operation is crucial.

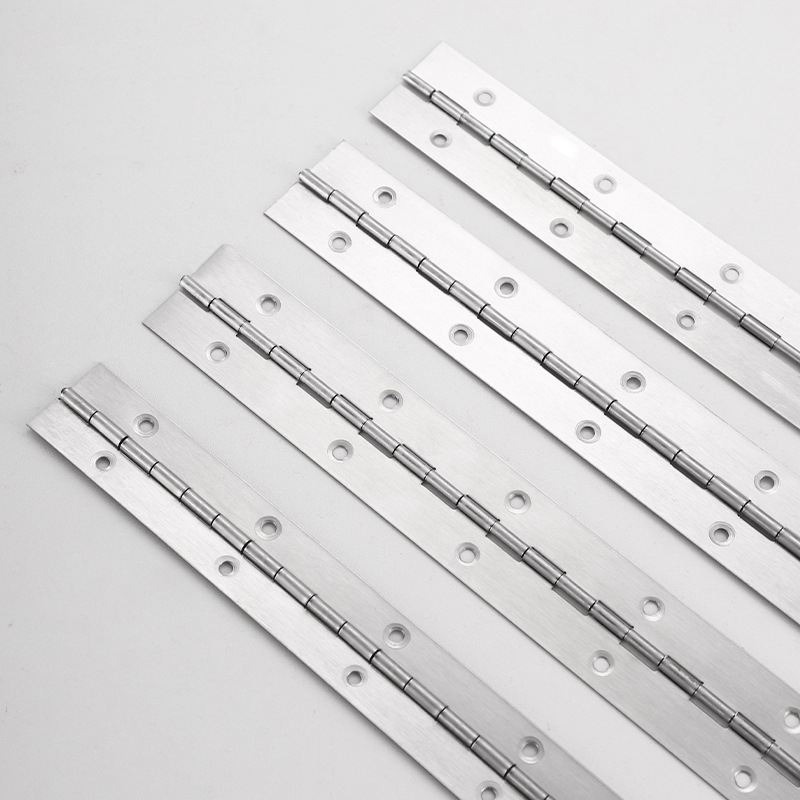

Continuous Hinges

Continuous hinges, also known as piano hinges, provide continuous support along the entire length of the door. They are characterized by their long, narrow design, which distributes the door’s weight evenly, enhancing stability and minimizing stress on the hinge points. Continuous hinges offer several benefits in industrial applications, including increased security, reduced maintenance, and enhanced longevity. They are commonly used in heavy duty exterior doors found in warehouses, factories, and other industrial facilities.

Strap Hinges

Strap hinges are known for their robust construction and ability to support heavy doors. They consist of a long strap with decorative or functional details, attached to the door and frame. Strap hinges offer advantages in heavy duty exterior applications, such as gate and barn door installations, due to their durability, load-bearing capacity, and aesthetic appeal. Industries such as agriculture, construction, and logistics often rely on strap hinges to ensure reliable operation of their exterior doors.

Industrial Pivot Hinges

Pivot hinges are designed to allow doors to rotate smoothly around a central pivot point. They offer a unique range of motion, allowing doors to swing in both directions or rotate a full 180 degrees. In heavy duty exterior installations, pivot hinges provide strength and stability, making them suitable for large or heavy doors. Industrial sectors such as manufacturing plants, hangars, and storage facilities benefit from pivot hinges’ ability to handle substantial loads while maintaining ease of operation.

Security Hinges

Security hinges are specifically engineered to enhance the security of heavy duty exterior doors. These hinges incorporate features such as non-removable pins, tamper-resistant fasteners, and reinforced construction to prevent unauthorized access and deter forced entry. Industries with high-security requirements, including data centers, government facilities, and financial institutions, prioritize the use of security hinges to protect their assets and maintain confidentiality.

Gate Hinges

Gate hinges are designed to withstand the unique challenges of heavy duty exterior gates. They are available in various types, including strap hinges, butt hinges, and adjustable hinges, offering versatility to accommodate different gate designs and sizes. Selecting the right gate hinge for industrial settings involves considering factors such as gate weight, frequency of use, and environmental conditions. Advancements in gate hinge technology, such as self-lubricating mechanisms and anti-corrosion coatings, further improve their performance and longevity.

Weld-On Hinges

Weld-on hinges provide a secure and permanent installation option for heavy duty exterior doors. These hinges are welded directly onto the gate or door frame, ensuring maximum strength and stability. Weld-on hinges are commonly used in industries that require long-lasting and tamper-resistant door solutions, such as automotive manufacturing, energy plants, and transportation hubs.

Bearing Hinges

Bearing hinges are engineered to support heavy doors with minimal friction and wear. They utilize ball bearings or roller bearings to distribute the door’s weight and facilitate smooth operation. Bearing hinges excel in heavy duty exterior scenarios where large and heavy doors are frequently opened and closed. Their unique design minimizes stress on the hinge points, reducing the risk of premature wear and damage.

Adjustable Hinges

Adjustable hinges offer flexibility in industrial environments where door alignment and precise positioning are crucial. These hinges allow for vertical and horizontal adjustments, enabling fine-tuning of the door’s position to ensure proper fit and operation. Adjustable hinges find applications in settings where changes in temperature, settling, or wear may affect the door’s alignment. They provide an effective solution for industries such as food processing, pharmaceuticals, and cleanrooms, where precise door sealing is essential.

Self-Closing Hinges

Self-closing hinges are designed to automatically close the door after opening, ensuring security, energy efficiency, and compliance with safety regulations. These hinges incorporate mechanisms such as springs or hydraulic systems that control the door’s closing speed and force. Industries that benefit from self-closing hinges include healthcare facilities, laboratories, and warehouses, where maintaining controlled access and environmental conditions is critical.

Conclusion

In conclusion, the selection of the right heavy duty exterior hinge is vital for optimizing industrial operations. Butt hinges, continuous hinges, strap hinges, pivot hinges, security hinges, gate hinges, weld-on hinges, bearing hinges, adjustable hinges, and self-closing hinges offer a range of options to meet specific industrial requirements. By understanding the characteristics, benefits, and applications of each hinge type, industries can ensure secure, reliable, and efficient door operation, enhancing productivity and safety in their respective operations.