In industrial applications, reliable dust containment is of utmost importance to ensure the smooth operation of processes and maintain product quality and safety. One crucial component that contributes to achieving reliable dust containment is the dust test chamber hinges. These hinges play a pivotal role in ensuring the effectiveness of dust containment systems, providing the necessary support and functionality. These hinges are identical to Truck Tailgate Hinges in that they are both hinges used on special equipment. They are not the usual hinges used in furniture, construction or decoration.

Understanding Dust Test Chamber Hinges

They are specialized hinges designed specifically for use in dust containment systems. They are engineered to meet the unique requirements of industrial environments, differentiating them from other types of hinges. These hinges enable the proper functioning of dust test chambers by allowing controlled access while maintaining a secure and airtight seal.

The Significance of Reliable Dust Containment

Dust contamination can have severe consequences in industrial processes, leading to product defects, equipment malfunction, and safety hazards. Reliable dust containment is essential to mitigate these risks and ensure optimal production outcomes. They play a critical role in achieving effective containment, preventing the ingress and egress of dust particles.

Exploring the Design and Construction of Dust Test Chamber Hinges

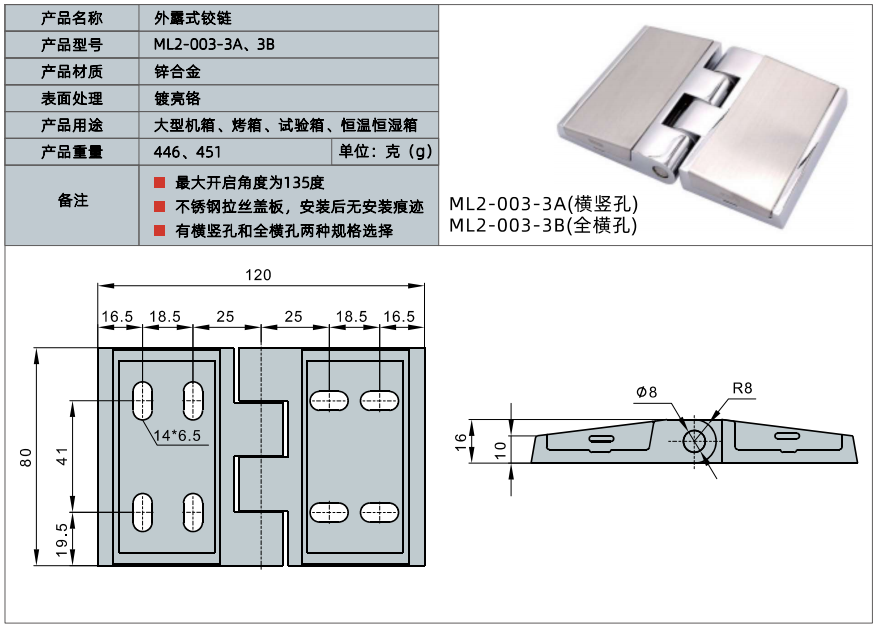

Chamber hinges are constructed using high-quality materials known for their durability and resistance to dust penetration. The design of these hinges takes into account factors such as load-bearing capacity, ease of operation, and sealing capability. Different hinge configurations are available, each with its advantages and disadvantages, allowing users to choose the most suitable option for their specific requirements.

Testing and Certification Standards for Dust Test Chamber Hinges

To ensure the reliability and performance of the hinges, they undergo rigorous testing and certification according to industry-specific standards. These standards validate the hinges’ ability to withstand harsh environmental conditions, maintain proper sealing, and provide long-lasting functionality. It is crucial to select hinges that meet these standards to ensure optimal performance and compliance.

Customization Options for Dust Test Chamber Hinges

Industrial applications vary widely, and customization is often necessary to meet specific requirements. These hinges can be tailored to accommodate different chamber sizes, access points, and environmental conditions. Collaborating with manufacturers specializing in the hinges allows businesses to obtain bespoke hinge solutions that align with their unique needs.

Installation and Maintenance Best Practices

Proper installation techniques are vital for the optimal performance of dust test chamber hinges. Precise alignment, adequate fastening, and appropriate sealing ensure the hinges function as intended. Regular maintenance and inspection are also necessary to detect and address any potential issues promptly. Lubrication and adjustment guidelines should be followed to prolong the lifespan of the hinges and maintain their functionality.

Enhancing Dust Containment Efficiency with Innovative Features

Advancements in dust test chamber hinge technology have introduced innovative features that further enhance dust containment efficiency. Sealing mechanisms, such as gaskets and compression seals, are integrated into the hinges to ensure a secure and airtight seal. Additionally, smart and IoT-enabled hinge solutions provide real-time monitoring and control, enabling proactive maintenance and optimizing containment effectiveness.

Real-World Applications and Success Stories

Examining real-world applications of dust test chamber hinges showcases their practical benefits across various industries. Case study 1 highlights how the use of these hinges improved dust containment in pharmaceutical manufacturing, leading to better product quality and compliance. Case study 2 demonstrates how dust test chamber hinges enhanced product quality control in the electronics industry. In case study 3, the implementation of these hinges ensured worker safety in chemical processing plants by preventing hazardous dust exposure.

Future Developments and Trends in Dust Test Chamber Hinges

Continued advancements in hinge materials contribute to improved durability and reliability. Manufacturers are exploring new materials and coatings that offer enhanced resistance to dust penetration, corrosion, and wear. Integration of automation and robotics in dust containment systems, coupled with intelligent hinge solutions, is

a growing trend. Additionally, sustainability initiatives focus on eco-friendly manufacturing practices and the use of recyclable materials in dust test chamber hinge production.

Conclusion

Reliable dust containment is crucial in industrial settings to maintain product quality, protect equipment, and ensure worker safety. Dust test chamber hinges play a pivotal role in achieving effective dust containment, providing the necessary support and sealing capability. To obtain tailored dust containment solutions, businesses are encouraged to consult industry experts who can provide guidance on selecting the appropriate dust test chamber hinges for their specific needs. By prioritizing reliable dust containment, companies can optimize their operations and mitigate potential risks.