In the industrial sector, cargo security is of utmost importance. Ensuring the safe transportation of goods is crucial for businesses to maintain customer satisfaction, protect valuable assets, and uphold industry standards. One integral component that plays a vital role in secure transportation is truck tailgate hinges. These hinges provide the necessary closure and stability for truck tailgates, safeguarding the cargo during transit. In this article, we will explore the significance of cargo security in the industrial sector and delve into the role that truck tailgate hinges play in ensuring secure transportation. These hinges are very different from European hinges as they are heavy duty hinges for outdoor use.

Understanding Truck Tailgate Hinges

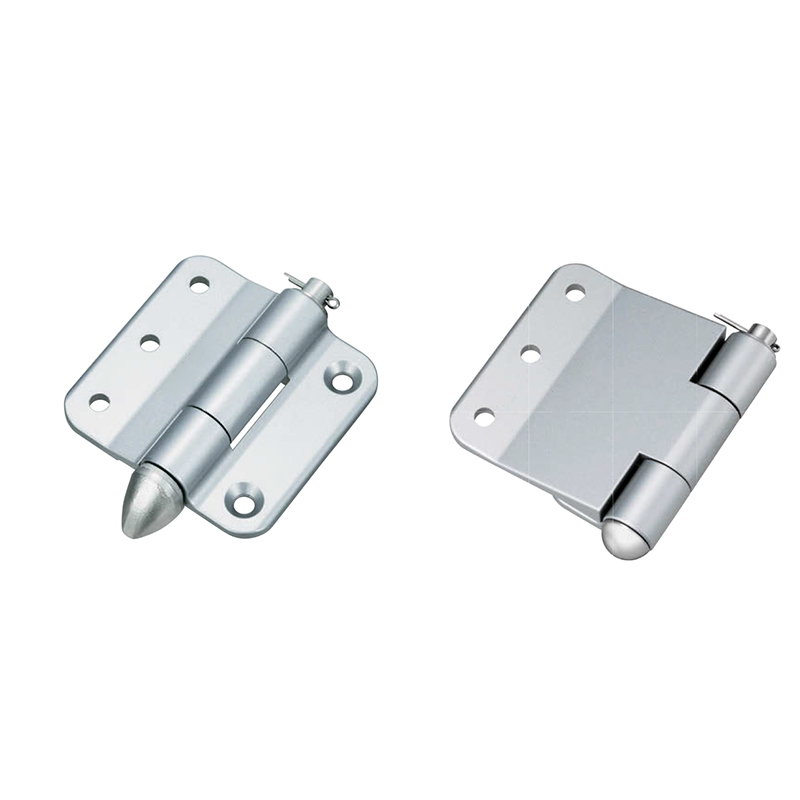

Truck tailgate hinges are mechanical components that enable the opening and closing of the tailgate, serving as the pivot points for the movement. These hinges come in various types, each designed to cater to specific industrial applications. By understanding the functionality and characteristics of these hinges, businesses can make informed decisions when selecting the most suitable hinges for their operations. Key considerations such as load capacity, durability, and ease of use must be taken into account to ensure optimal performance and longevity.

Ensuring Proper Closure and Stability

Proper closure and stability of the tailgate are crucial for cargo security during transportation. Truck tailgate hinges play a significant role in achieving secure closure, preventing any gaps or loose ends that may compromise the cargo. With sturdy hinges in place, the tailgate can be tightly sealed, reducing the risk of cargo shifting or falling out of the truck. Inadequate closure not only exposes the cargo to damage but also poses safety hazards to other road users. Therefore, investing in reliable truck tailgate hinges is essential to ensure the overall security of the cargo.

Preventing Accidental Opening during Transportation

Accidental opening of the tailgate during transit can have severe consequences, including cargo spillage and accidents. Truck tailgate hinges incorporate safety measures to prevent such incidents from occurring. These safety features, such as latches, locks, and secure fastening mechanisms, ensure that the tailgate remains securely closed throughout the journey. By employing these preventive measures, businesses can mitigate the risks associated with accidental opening, protecting both the cargo and the public.

Enhancing Cargo Security and Theft Prevention

Truck tailgate hinges play a crucial role in enhancing cargo security and preventing theft. Secure tailgate hinges act as a deterrent for unauthorized access to the cargo area, as they make it significantly more challenging for potential thieves to gain entry. Furthermore, specialized anti-theft features and technologies are often integrated into these hinges to provide an additional layer of protection. These may include tamper-proof locking systems, alarm sensors, or GPS tracking capabilities. By investing in secure tailgate hinges, businesses can minimize the risk of cargo theft and safeguard their valuable assets.

Materials and Construction for Robust Hinges

To ensure the strength and durability of truck tailgate hinges, manufacturers utilize various materials in their construction. Common materials include stainless steel, aluminum alloys, and heavy-duty polymers. Each material has its advantages and disadvantages in terms of strength, corrosion resistance, and weight. Businesses must carefully consider these factors to select the most suitable hinge material for their specific applications. Making informed decisions regarding material selection is crucial for ensuring the longevity and reliability of the hinges in demanding industrial environments.

Load-Bearing Capacity and Heavy-Duty Usage

In industrial applications, truck tailgate hinges must withstand heavy loads and rigorous usage. Load-bearing capacity is a critical consideration when selecting hinges, as it determines the maximum weight the hinges can support. Various factors can affect the load-bearing capacity, including the materials used, hinge design, and reinforcement techniques. Manufacturers often subject their hinges to rigorous testing and certification processes to ensure that they meet industry standards for strength and durability. By understanding load-bearing capacity and choosing hinges accordingly, businesses can maintain the integrity and security of their cargo.

Installation and Maintenance Best Practices

Proper installation and regular maintenance are essential to ensure the optimal performance of truck tailgate hinges. During installation, proper alignment and adjustment techniques must be followed to ensure that the hinges function smoothly and securely. Regular inspection and lubrication are also crucial to prevent hinge malfunction and ensure smooth operation. Additionally, businesses should be aware of common issues that may arise with truck tailgate hinges and know how to troubleshoot them effectively. By adhering to best practices for installation and maintenance, businesses can extend the lifespan of their hinges and minimize the risk of unexpected failures.

Innovative Features and Advancements

Advancements in truck tailgate hinge technology have led to the introduction of innovative features that enhance performance and security. Manufacturers have introduced advanced materials and corrosion-resistant coatings to improve durability and longevity. Safety mechanisms, such as anti-slam features, have been integrated to prevent accidental injuries during tailgate closure. Moreover, smart and IoT-enabled hinge solutions are being developed, allowing for enhanced monitoring and control of the tailgate’s status and security. Staying informed about these innovative features and advancements enables businesses to leverage the latest technologies and optimize their cargo security measures.

Real-World Applications and Success Stories

Examining real-world applications and success stories can provide valuable insights into the practical implementation of truck tailgate hinges. Case study 1 focuses on how logistics companies have streamlined their cargo transportation processes using tailored hinge solutions, resulting in improved efficiency and reduced operational costs. Case study 2 explores how the construction and mining industries have enhanced productivity by employing robust hinges that withstand heavy loads and extreme conditions. Case study 3 highlights how secure tailgate hinges have ensured safe and secure deliveries in the transportation sector, minimizing the risk of cargo damage and theft. These real-world examples demonstrate the tangible benefits that businesses can achieve by prioritizing the selection of high-quality truck tailgate hinges.

Future Trends in Truck Tailgate Hinges

The future of truck tailgate hinges holds exciting possibilities for the industrial sector. Integration with telematics and fleet management systems is expected to enhance monitoring and control capabilities, enabling businesses to track and optimize their cargo security in real time. Sustainability initiatives are driving advancements in hinge manufacturing, with an emphasis on eco-friendly materials and processes. Additionally, technological advancements such as improved hinge designs and mechanisms will further enhance hinge performance, providing businesses with even greater reliability and security in their operations.

Conclusion

Cargo security is vital in the industrial sector, and truck tailgate hinges are essential for safe transportation. These hinges provide closure and stability, preventing cargo from shifting or opening accidentally. They also deter theft with anti-theft features. Material selection, load-bearing capacity, and proper installation and maintenance are crucial for hinge performance. IHINGES is a professional manufacturer of truck tailgate hinges. We welcome you to contact us anytime to get the most suitable solutions and pricing.