In the industrial sector, test equipment hinges play a crucial role in ensuring optimal efficiency and durability. These often-overlooked components contribute significantly to the smooth operation and longevity of various industrial applications. This article provides an overview of how test equipment hinges contribute to efficiency and durability, highlighting their importance in the industrial landscape.

Understanding the Role of Test Equipment Hinges

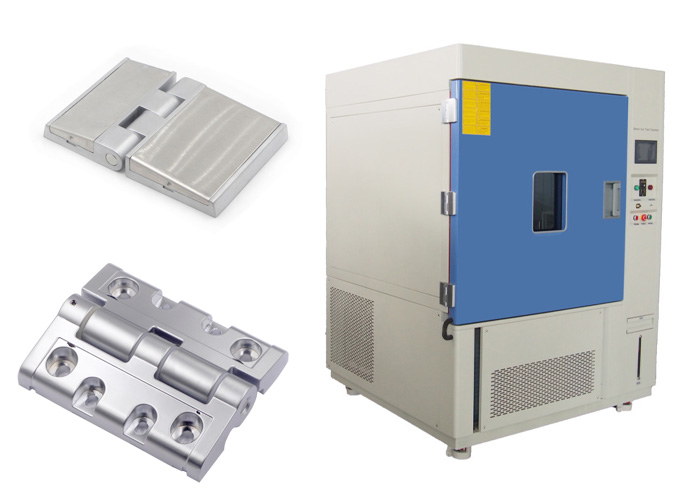

Test equipment hinges are specially designed components used in industrial applications to facilitate the movement and functionality of doors, panels, and other equipment. They serve as pivotal points, allowing smooth opening and closing while providing stability and security. By enabling proper movement and alignment, hinges contribute to the overall efficiency and longevity of the equipment.

Factors to Consider When Choosing Test Equipment Hinges

A. Load-Bearing Capacity

When selecting test equipment hinges, it is crucial to consider their load-bearing capacity. Industrial environments often require hinges capable of supporting heavy loads, as equipment doors and panels may be substantial. Choosing hinges with the appropriate load-bearing capacity ensures optimal performance, prevents premature wear, and enhances safety.

B. Material Selection

The choice of materials for manufacturing test equipment hinges significantly impacts their durability and performance. Common materials include stainless steel, zinc alloy, and other robust alloys. Stainless steel hinges offer excellent resistance to corrosion, making them suitable for challenging industrial environments. Zinc alloy hinges, on the other hand, provide a balance of strength and cost-effectiveness. Understanding the advantages and characteristics of different materials helps in selecting the most suitable option for specific industrial applications.

C. Design and Functionality

The design and functionality of test equipment hinges directly impact their efficiency and durability. Different hinge designs cater to various industrial requirements. For example, continuous hinges provide consistent support along the entire length of the door, offering enhanced stability and durability. Concealed hinges offer a streamlined appearance while ensuring efficient operation. Understanding how specific designs enhance efficiency and durability helps in making informed decisions when selecting hinges for industrial equipment.

Selecting the Right Type of Test Equipment Hinges

A. Concealed Hinges

Concealed hinges are a popular choice in industrial settings due to their sleek design and hidden installation. These hinges provide a clean and aesthetically pleasing appearance while optimizing efficiency and durability. They are commonly used in cabinets, enclosures, and other equipment where a seamless and secure operation is desired. Concealed hinges excel in applications that require smooth movement, reduced maintenance, and improved security.

B. Continuous Hinges

Continuous hinges, also known as piano hinges, offer exceptional durability and stability. They consist of a single continuous strip of metal that runs along the entire length of the door or panel. Continuous hinges distribute the load evenly, reducing stress on individual hinge points. This design enhances the longevity of the hinges and the equipment, making them suitable for heavy-duty applications.

C. Butt Hinges

Butt hinges are a classic hinge design widely used in the industrial sector. They consist of two plates joined together by a central pin, allowing the door or panel to swing open and closed. Butt hinges are versatile and can be easily installed and maintained. They offer reliable performance and durability, making them suitable for a wide range of industrial applications.

Installation and Maintenance Best Practices

A. Proper Installation Techniques

To ensure the optimal performance and durability of test equipment hinges, proper installation techniques are essential. This section provides a step-by-step guide to correctly install hinges, including alignment, positioning, and fastening methods. Following these guidelines helps to ensure a secure and durable hinge installation that maximizes efficiency and longevity.

B. Regular Maintenance and Inspection

Regular maintenance is crucial for preserving the functionality and durability of test equipment hinges. This section emphasizes the importance of periodic inspections and maintenance routines. It provides an inspection checklist that includes lubrication, cleaning,

and checking for wear or damage. By addressing potential hinge issues proactively, industrial equipment can continue to operate smoothly and efficiently.

Case Studies: Real-World Examples

This section presents real-world examples that showcase the successful optimization of efficiency and durability with test equipment hinges. It highlights specific industries or applications where the choice of hinges made a significant impact. By examining these case studies, readers gain insights into the practical benefits of selecting the right hinges for their industrial equipment.

Future Trends in Test Equipment Hinges

The field of test equipment hinges continues to evolve with advancements in technology and manufacturing processes. This section explores emerging trends and innovations that shape the future of hinge design. It discusses advancements in materials, smart hinges, and other technologies that aim to further optimize efficiency and durability in industrial applications.

Conclusion

Choosing the right hinges for test equipment is crucial to optimize efficiency and durability in the industrial sector. This article provided an in-depth understanding of the role of test equipment hinges, factors to consider during the selection process, and the importance of proper installation and maintenance. By emphasizing the significance of hinges in industrial applications, we underscored the importance of making informed decisions to ensure optimal performance and longevity for industrial equipment.