Step hinges are an integral component of industrial machinery that facilitate the opening and closing of doors and panels. It belongs to industrial hinges. They are designed to handle heavy loads and provide smooth movement, making them essential for machinery with frequent use. In this article, we’ll explore the key considerations for selecting the right step hinges to ensure optimal performance and longevity of your machinery.

Load Capacity and Weight Rating of Step Hinges

One of the most important factors to consider when selecting step hinges for industrial machinery is the load capacity and weight rating of the hinges. Here’s what you need to know:

Understanding Load Capacity and Weight Rating for Step Hinges

Load capacity refers to the maximum amount of weight a step hinge can support while still functioning properly. The weight rating of a step hinge is typically provided by the manufacturer and is an indication of the load capacity of the hinge.

Determining the Load Capacity Requirements for Your Machinery

To determine the load capacity requirements for your machinery, you need to consider the weight of the equipment and any additional weight that may be added during use. This includes any products or materials that will be placed on or moved by the machinery.

Once you have determined the total weight, you can then choose step hinges with an appropriate load capacity rating. Choosing a hinge with a load capacity that is too low can result in equipment failure and safety hazards.

Selecting the Appropriate Weight Rating for Your Equipment

When selecting step hinges, it is important to choose a weight rating that is appropriate for your equipment. This will ensure that the hinges can safely support the weight of the machinery and any additional weight that may be added during use.

It is also important to consider factors such as the frequency and intensity of use, as well as the operating environment and conditions. Selecting a hinge with a higher weight rating than necessary may result in unnecessary costs while selecting one with a lower weight rating can compromise the safety and performance of your machinery.

Materials and Finishes for Step Hinges

Step hinges can be made from a variety of materials, each with its own advantages and disadvantages. Some common materials used for step hinges include steel, stainless steel, aluminum, and plastic. Steel is a popular choice due to its strength and durability, while stainless steel is ideal for use in harsh environments due to its corrosion resistance. Aluminum is lightweight and corrosion-resistant, making it a good choice for applications where weight is a concern. Plastic is another option, offering good corrosion resistance and affordability, but may not be as durable as other materials.

When selecting a material and finish for your step hinge, it’s important to consider the specific requirements of your application. Factors such as the operating environment, load capacity, and durability requirements should all be taken into account. For example, if the hinge will be used in a corrosive environment, a material with good corrosion resistance should be chosen.

In addition to material selection, it’s also important to consider the finish of the step hinge. Some common finishes include plain, zinc-plated, and powder-coated. Plain finishes are typically the most affordable but may not offer the same level of corrosion resistance as other finishes. Zinc-plated finishes offer good corrosion resistance and are ideal for outdoor applications. Powder-coated finishes provide a durable, long-lasting finish that can be customized to match the color of the machinery or equipment.

When selecting a material and finish for your step hinge, it’s important to ensure compatibility with the materials of the machinery or equipment it will be used on. Incompatible materials can lead to corrosion, wear, and other issues that can affect the performance and lifespan of the hinge. Consider consulting with a professional or the manufacturer of your machinery to ensure that the materials of the hinge and machinery are compatible.

Operating Environment and Conditions

When selecting step hinges for industrial machinery. It’s important to consider the operating environment and conditions in which they will be used. Understanding these factors will help determine the appropriate step hinge type for your machinery and ensure optimal performance.

Firstly, it’s essential to have a clear understanding of the operating environment and conditions of your machinery. This includes factors such as temperature, humidity, vibration, and exposure to dust or chemicals. These factors can have a significant impact on the performance and longevity of your step hinges.

Next, it’s crucial to determine the appropriate step hinge type for different environmental conditions. For example, in high-temperature environments. It’s important to select step hinges made from materials that can withstand heat, such as stainless steel. In environments where there is exposure to moisture or chemicals, corrosion-resistant coatings may be necessary.

It’s also important to consider the potential impact of temperature, humidity, and other factors on step hinge performance. For example, high humidity levels can cause metal components to corrode and reduce the load capacity of the hinges.

By taking the time to understand the operating environment and conditions of your machinery, you can select step hinges that are appropriate for the specific requirements of your equipment. This will help ensure optimal performance and longevity of your machinery, as well as reduce the risk of downtime and maintenance costs.

Type of Mounting and Installation Requirements

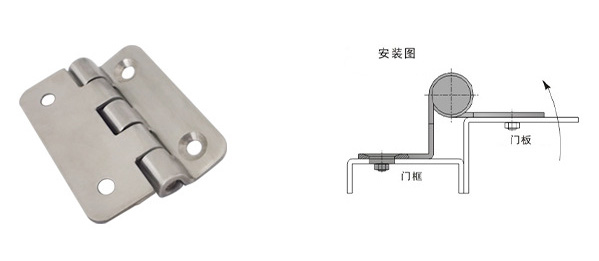

Mounting and installation are critical factors to consider when selecting step hinges. There are different types of mounting and installation methods available for step hinges. And it’s crucial to choose the appropriate one based on your machinery type and application.

It’s essential to have a clear understanding of the tools and equipment required for installation before selecting a step hinge. In general, the installation process involves attaching the hinge to the machinery using screws or bolts. The mounting and installation method may vary depending on the machinery’s size, shape, and weight. So it’s crucial to select the appropriate method carefully.

Cost and Budget Considerations

Cost and budget considerations are crucial when choosing step hinges for your machinery. The first step is to determine your budget and identify the cost factors for the hinge. In addition to the initial cost, you should also consider the long-term costs. Such as maintenance and replacement. While it’s essential to consider the quality of the hinge. You should also ensure that it’s cost-effective and aligns with your budget.

To balance cost considerations with the need for high-quality step hinges, it’s essential to understand the tradeoffs between cost and quality. A lower-priced hinge may seem like a better option initially, but it may not offer the same level of durability and reliability as a more expensive option. It’s important to assess the quality of the hinge and ensure that it meets the necessary load capacity and weight rating requirements.

When selecting a step hinge, you should consider the value it provides for its cost. An expensive hinge may not always be the best option if it doesn’t offer the necessary features. Or benefits required for your machinery. On the other hand, a lower-priced hinge may not provide the same level of performance or durability required for your equipment. Ultimately, you should aim to choose a hinge that offers the best value for your budget. Balancing cost considerations with the need for high-quality step hinges.

Conclusion

Selecting the right step hinges is critical to ensure the optimal performance and longevity of your industrial machinery. By considering load capacity, materials, finishes, mounting, and installation requirements. Operating environment and conditions, and cost and budget considerations. You can make an informed decision and choose the best step hinges for your machinery. Don’t hesitate to consult with a professional for further guidance and assistance in choosing the right step hinges for your machinery.