Description

Continuous hinges for automation equipment are hinges that run the entire length of a door or panel, providing continuous support and stability. They are commonly used in automated systems, such as conveyor belts or assembly lines, where doors or panels need to open and close repeatedly.

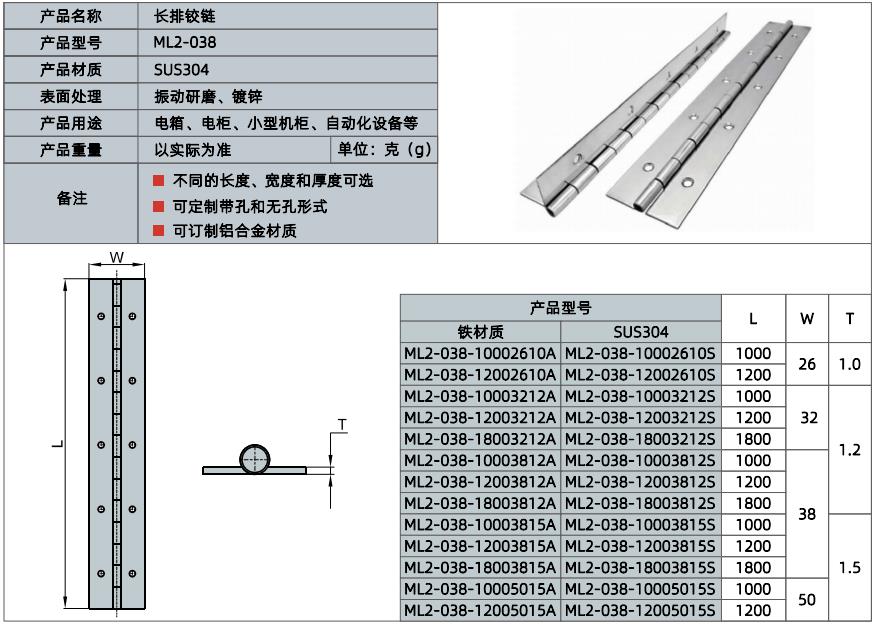

Continuous hinges for automation equipment are typically made of steel and come in various sizes to accommodate different door or panel sizes. They feature interlocking leaves that distribute the weight of the door or panel evenly along the entire length of the hinge. This helps to prevent sagging, misalignment, or other issues that can occur with traditional hinges.

Features:

- Continuous support: These butt hinges provide continuous support along the entire length of a door or panel, ensuring stability and preventing sagging or misalignment.

- Durability: Made of steel, continuous hinges are durable and long-lasting, able to withstand frequent use and heavy loads.

- Versatility: Continuous hinges come in a variety of sizes to accommodate different door or panel sizes, making them suitable for a wide range of automation equipment applications.

- Security: Continuous hinges can be designed with security features, such as tamper-resistant pins, to prevent unauthorized access to equipment or materials.

- Easy installation: Continuous hinges are easy to install and can be mounted using a variety of methods, including welding or screwing.

FAQs:

1. What is a continuous hinge for automation equipment?

A continuous hinge for automation equipment is a type of hinge that runs the full length of a door or panel. Providing continuous support and stability. It is commonly used in automated systems. Such as conveyor belts or assembly lines, where doors or panels need to open and close repeatedly.

2. What are the benefits of using continuous hinges for automation equipment?

The benefits of using continuous hinges include continuous support, durability, versatility, and security. And ease of installation. They provide stable support along the entire length of a door or panel, are long-lasting. And can withstand heavy loads, and come in various sizes. Can be designed with security features, and are easy to install.

3. How do I choose the right continuous hinge for my automation equipment?

To choose the right continuous hinge for your automation equipment. You need to consider the size and weight of the door or panel, and the frequency of use. And the level of security required. You also need to ensure that the hinge is compatible with the type of mounting method used for the door or panel.

4. Can continuous hinges be customized for specific automation equipment applications?

Yes, continuous hinges can be customized for specific automation equipment applications. They can be designed to meet specific load capacities, security requirements, and mounting methods. Custom continuous hinges are often used in specialized equipment or systems.

5. How do I install continuous hinges on my automation equipment?

The installation process for continuous hinges may vary depending on the specific application and type of mounting method used. Generally, the hinges are attached to the door or panel first. And then to the equipment frame using screws or other fasteners. It is important to ensure that the hinge is securely attached to prevent misalignment or sagging.