Heavy-duty weld hinges are also a widely used type of hinge in industrial equipment. The only difference between it and other industrial hinges is the way it is mounted. As you can see from the name of this type of hinge, it is mounted on the door by welding. That is why they are called welded hinges.

This article focuses on 5 types of heavy-duty welded hinges. If you are a hardware buyer for your company or an industrial equipment manufacturer, it may be helpful to you.

What are the heavy-duty weld hinges?

What are heavy-duty welded hinges? Literally, they are a class of heavy-duty industrial hinges that are mounted using a welded method. These hinges are not very different from other types of hinges. The main difference is that there is no hole in the hinge block. This is because these hinges do not require bolt mounting, but only welded mounting.

They are mainly used on some industrial heavy doors. They can be easily welded to doors and door frames without the need for pre-cutting holes and preparing bolts. This type of installation provides a sturdy and secure-looking connection between the door and the frame.

Also known as barrel hinges and lift-off hinges, they provide a strong, compact, and attractive method of attaching metal doors to metal frames for electrical, agricultural, security, safes, tool cabinets, gates, fences, and many other industrial applications. Welded hinges are available in steel, stainless steel, and aluminum with steel, brass, and stainless steel pins.

What are the features of heavy-duty weld hinges?

Heavy-duty weld hinges are characterized by welded installation. This is its most important feature. This type of installation provides a more secure and strong connection. It just seems inconvenient when it comes to maintenance or replacement. Hinges without bolt mounting are easy to replace and maintain.

Welded installation requires ensuring that the two weldments are weldable. For example, iron is weldable, and stainless steel is weldable. But aluminum or zinc alloy material is generally not weldable. Therefore, before using the welding installation method, make sure that the hinge and the door material can be welded installation.

Types of heavy-duty welded hinges

I have compiled a list of 5 types of heavy-duty welded hinges. So that you have a reference when looking for these types of hinges. There are various factors in the way the types are classified. There are those divided by their structure, those divided by their application, and those divided by historical reasons. These different ways of classification actually have only one purpose. That is to facilitate the communication between hinge manufacturers and customers.

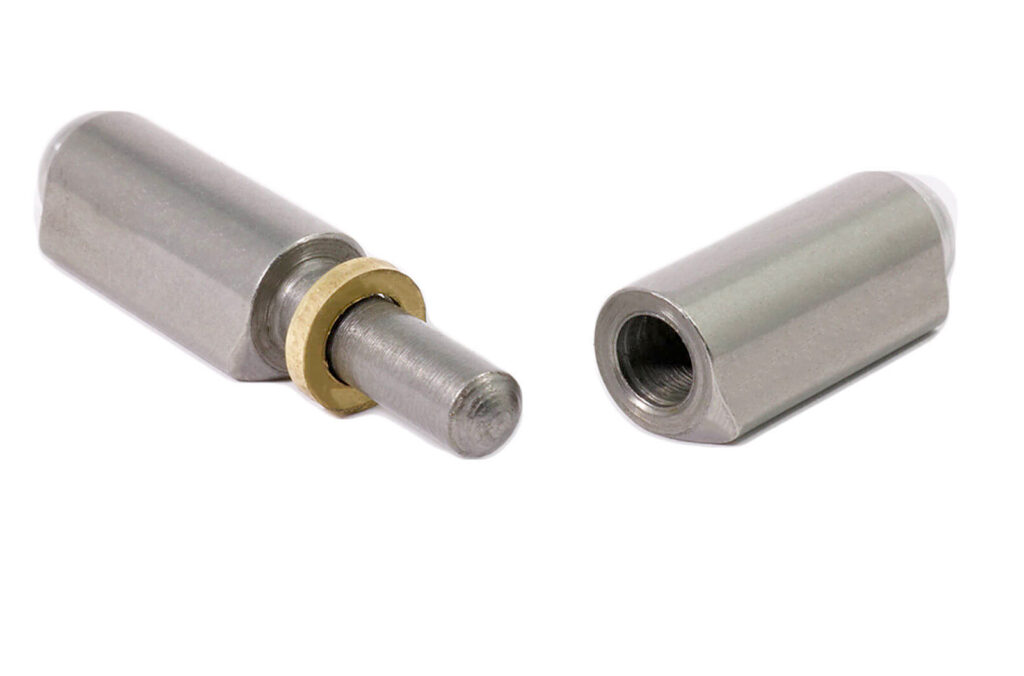

Bullet welded hinges

This bullet weld hinge is the most common type of welded hinge. They are generally made of stainless steel. Sizes are generally 60mm, 80mm, 100mm, and 120mm. 8mm, 10mm, 12mm, and 14mm diameters are available.

Bullet welded hinges have a simple structure, similar to two columns. There is some extra material in the welding part, which is to facilitate welding. This design allows the welder to know from which position to start welding when welding installation.

A copper spacer is usually added in the middle of the connection between the two hinge blocks. Its function is to avoid friction between the hinge blocks. And it acts as a cushion.

Butt Weld Hinges

Butt weld hinges are actually similar to the butt hinges we normally see. Only there are no mounting holes in the hinge block. The structure of this type of hinge can also be varied. Only the choice of the material requires attention. A butt weld hinge cannot be made of a non-metallic material. This would not allow for welded installation.

The two hinge blocks of a butt weld hinge are equal in size and symmetrical to each other. This type of hinge is the most widely used and is the one we see everywhere in our daily lives. However, the welded hinge is only used in industrial equipment. Some outdoor electrical boxes and cabinets have anti-theft requirements. Then you can directly weld the hinge block with the door and door frame so that you do not have to worry about the hinge being disassembled.

Although we can use industrial concealed hinges installation, welding hinges are more convenient and quick to install.

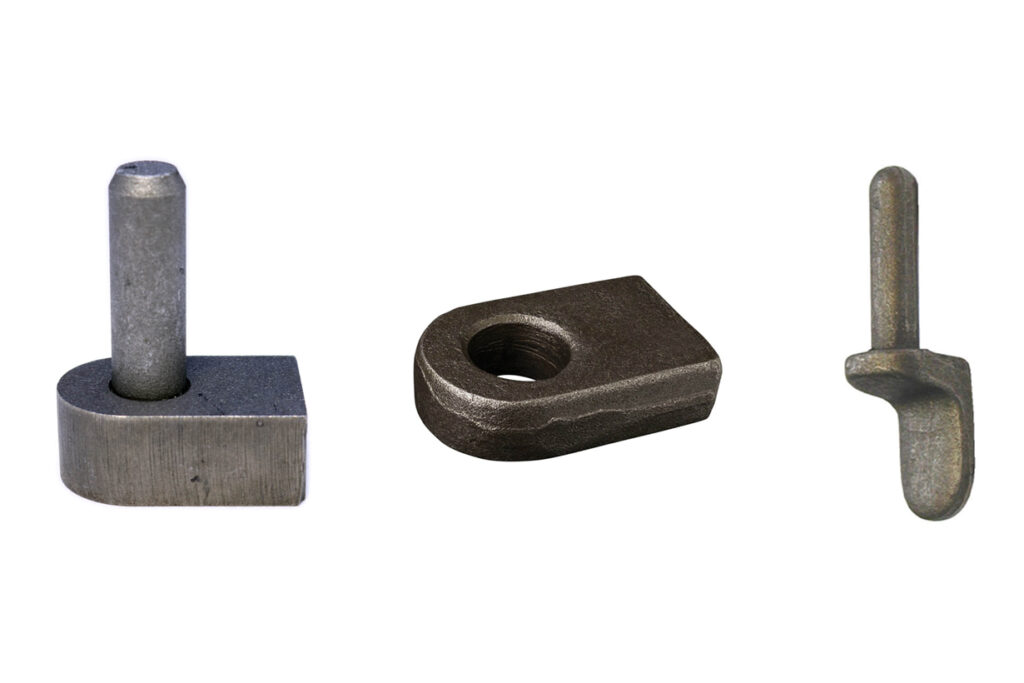

Welded door hinges

Welded hinges for doors are generally simple structural hinges used on some doors. These hinges do not need to be complex and beautiful to look at. It is only necessary to achieve the required function and to have enough structure. Therefore, the structure of these welded hinges is generally simple. This is shown in the picture below.

Welded piano hinges

Piano welded hinges belong to the category of piano hinges. Common piano hinges will have holes cut in the hinge block at regular intervals and are screw mounted. Then with the welded method, holes are required. A piano-welded hinge can also be called a continuous welded hinge. It is a long type of hinge. When installed on a door, it provides a very stable and strong support force.

IHINGES is able to provide professional development and production of piano hinges. We have provided many customers with custom-made welded piano hinges. The most frequent cases are made of stainless steel.

Strap Weld Hinges

A strap weld hinge is a type of industrial band hinge. It is a shape with very wide hinge blocks on the left and right sides. Or one side is narrow and the other side is very wide, as shown in the figure below. This type of hinge is also often installed with welding, so it is called a strap welded hinge.

You may often see hinges of this construction on garden and fence gates. But what we are talking about here mentions hinges used on industrial equipment. They are much bigger and stronger in structure and load-bearing.

Conclusion

The 5 types of heavy-duty weld hinges summarized above are only some of them. In fact, any structure of industrial hinges can be converted to a welded installation. Just make sure that the material is suitable for welded installation. Because the difference here is only the installation method. There are even hinges that are already open-ended that can be welded.

If you are looking for a hinge manufacturer, then you have come to the right place. You can always contact us for detailed proposal advice.