The hinge products used in the industry have many special functions. The different parts determine the structure and name of the hinge. Hinges generally require load-bearing properties to meet requirements, and different equipment doors have different load-bearing requirements. In addition, different structures also determine different installation trials.

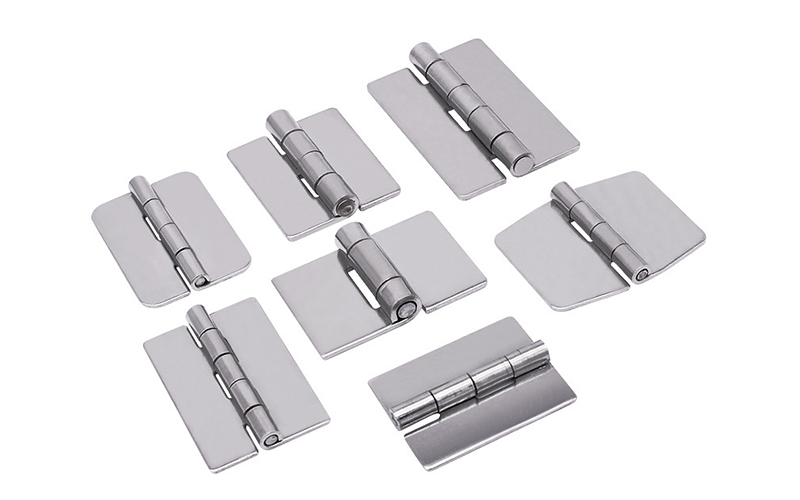

The hinge to be introduced today is a widely used type of hinge in the field of industrial equipment. It has a more robust load-bearing capacity than ordinary furniture hinges, is installed by welding, and is also one of our most common structures. These hinges are called heavy-duty stainless exterior butt hinges without holes. Butt hinges are a series of hinges that we specialize in and we have a large number of products in stock.

What are the heavy-duty butt hinges?

Heavy-duty butt hinges are a class of industrial hinges with high load-bearing capacity. Usually, these hinges have two hinge blocks that are equal in size and symmetrical. The two hinges are connected together by means of hinge pins so that the two hinges can rotate against each other. Some heavy-duty butt hinges have additional spacers between the two hinge blocks to prevent excessive wear caused by friction between the two hinge blocks.

IHINGES hinges of this type generally have nylon spacers added to prevent wear and tear on the one hand, and to provide a silent and cushioning function on the other. This is usually found in hinges made of zinc alloy. In the case of stainless steel, additional spacers are generally not required.

What are the heavy-duty stainless butt hinges?

Heavy-duty stainless steel butt hinges are also heavy-duty butt hinges, but here we are emphasizing the material. Stainless steel is widely used in the production of industrial hinges, especially heavy-duty butt hinges, because of the high requirements for strength and load-bearing, and customers who are more concerned about safety factors will choose to use stainless steel.

Heavy-duty stainless butt hinges generally do not require additional spacers to prevent wear or damage to the surface. This is because the material has good anti-corrosion properties. We only need to add some lubricant during the maintenance process. Stainless steel material has 304 and 316 material, if your product is used in the seaside or sea, you need to use 316 stainless steel material to play the function of anti-corrosion.

What are the heavy-duty exterior butt hinges?

Heavy-duty exterior butt hinges are heavy-duty hinges that are mounted on the exterior of the equipment or installed outdoors. These hinges are generally mounted on the surface of the equipment door as opposed to concealed hinges that are mounted concealed. Because these hinges are larger in size and have strong load-bearing properties, they may not meet these performance requirements if they are designed as concealed hinges.

There are also certain differences as to whether they are used indoors or outdoors. In the case of indoor use, the use environment is dry and there is no direct sunlight or rain. So in this case performance requirements can be achieved by using lower-cost materials. For example, iron or zinc alloy material.

If it is used outdoors, the hinges will be used in a comprehensive consideration of which material, generally will use stainless steel hinges. Therefore, for heavy-duty exterior butt hinges, it is important to consider the environment in which it will be used according to the actual situation.

What is the butt heavy-duty hinges without holes?

Butt heavy-duty hinges without holes mainly emphasize the hinge mounting method, and hinges without holes are used for welded mounting. This is a more niche type of mounting method. Most of the hinges made by IHINGES have mounting holes. This is especially true for industrial hinges made of iron or zinc alloy.

Butt heavy-duty hinges without holes are generally used in special cases, such as on outdoor equipment doors, and are used less frequently, but need to ensure that the case is sturdy. Butt heavy-duty hinges without holes are generally used in some special requirements, such as in some outdoor equipment doors, and the frequency of use is relatively low, but need to ensure that the box is strong.

This type of hinge installation needs to be installed in place once, otherwise, it will be very troublesome to make adjustments during the installation process. It is not easier to adjust than the hinges with holes.

How to order heavy-duty stainless hinges without holes

If you want to order heavy-duty stainless exterior butt hinges without holes, then we can provide you with professional solutions and high-quality products. We are a manufacturer of industrial hinges from China, specializing in the development and production of industrial hinges. We have our own factory and a large stock of regular products. Welcome to contact us at any time.

Two types of hinges are recommended

This hinge is 70*80mm in shape, 3mm in thickness, and 238g in weight. 10mm in diameter, so it has a good load-bearing capacity of at least 50 kg. These heavy-duty stainless exterior butt hinges without holes are usually rough parts. Because customers clean the surface after welding and installation or paint them together with the equipment.

The size of the hinge blocks on both sides of this welded hinge is different. Mainly because the door frame is narrower and the door panel is wider. The overall dimension is 105*50mm. The material thickness is 3mm, the pin diameter is 8mm, and the individual weight is 142g.

The above is an introduction to heavy-duty stainless exterior butt hinges without holes. This may be helpful if you are a manufacturer of the equipment. Or sheet metal structures and need to use these industrial hinges. Our strength is to customize industrial hinges for our customers. So feel free to contact us with your requirements, and we are sure we can give you a satisfactory solution.