In the production process of environmental test chambers, a lot of hardware is used, such as door locks, hinges, vent fittings, and threading hoses. Among them, hinges are one of the more critical types of hardware.

This article will focus on introducing you to the 10 heavy-duty door hinges used in environmental testing equipment. If you happen to be a manufacturer of testing equipment and are purchasing industrial hinges for your equipment, then perhaps this article can be a reference for you.

Before formally introducing heavy-duty door hinges, it is still necessary to submit to the general reader what environmental testing equipment is and its role.

What are environmental test chambers

environmental test chambers are actually a general term for a class of equipment that is mainly used to simulate various natural climatic environments. Simulation of different climates will use different environmental test chambers. Among the representative products are salt spray test chambers, high and low-humidity test chambers, industrial ovens, etc. There is also a lot of simulation of other climatic test chambers.

We know that testing the performance of a pavilion in the natural environment may take a long time to test. This will affect the production cycle of the product and is not a realistic approach. Then if this problem needs to be solved, it is only through this type of professional testing equipment that can simulate the effects of natural climate on the product over a long range of time in a short period of time.

The working principle of environmental testing equipment is to simulate various types of natural climatic environments, in which the parts to be tested are placed, to test whether the performance indicators of the parts meet the design expectations. And the test report is issued.

What are gate heavy-duty hinges?

So, we have understood what is the environmental test chambers, and the next focus on what is on the gate heavy-duty hinges. As the name implies, it is a class of hinges with strong load-bearing properties. This type of hinge size structure is a little larger than the general ordinary household hinges, and the structure is more rugged. It is mainly used for installation on doors of various special equipment in the industrial field.

Different equipment will be installed with different gate heavy-duty hinges, but the principle of the hinge is the same. They are all used to connect the door to the door frame and until the load-bearing role. It is just a matter of using different sizes and configurations of hinges depending on the size and construction of the door.

Below I will list 10 gate heavy-duty hinges produced by IHINGES that are professionally used for various environmental test chambers, so you can make a reference if you are a manufacturer of such equipment. These products are all regular IHINGES products and are available in large quantities from stock. You can contact us now to order products at any time.

The first gate heavy-duty hinges

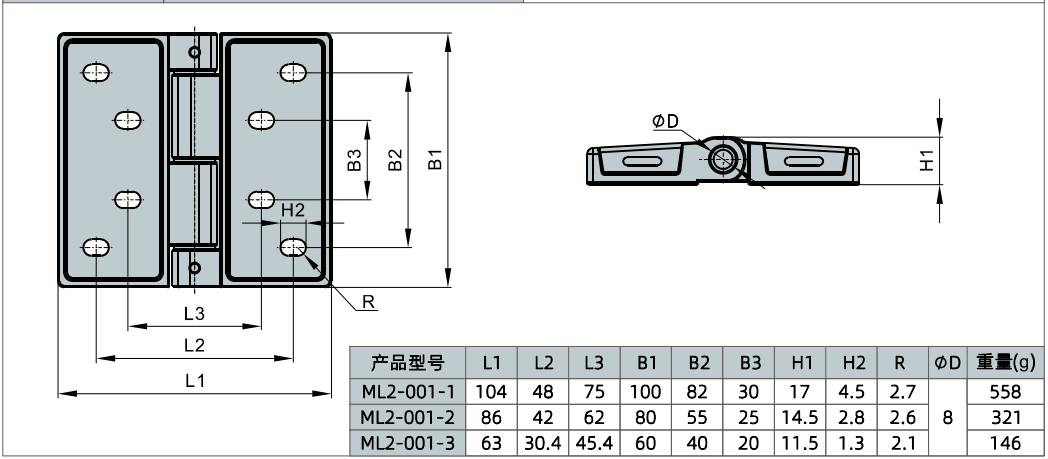

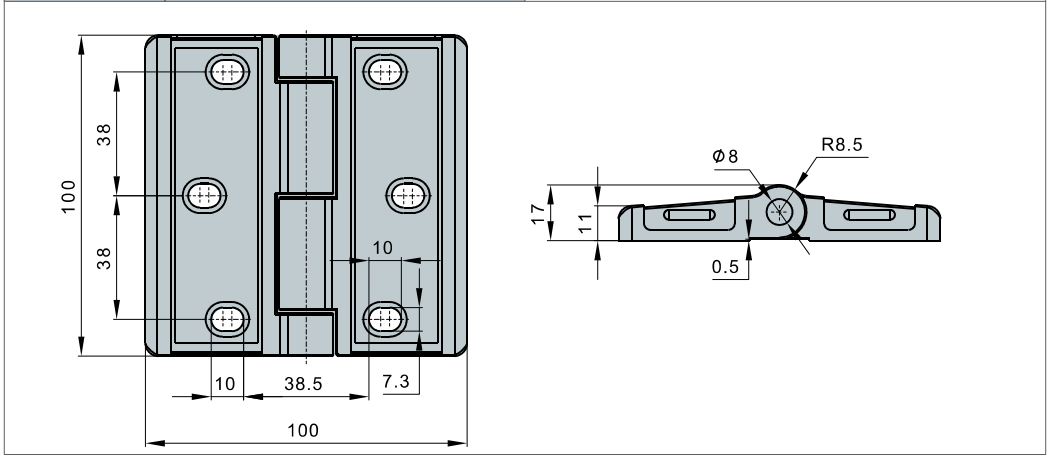

This gate heavy-duty hinge is made of zinc alloy with a chrome-plated finish. The mounting holes are of a long round hole design, and the position can be adjusted during installation, with a maximum opening angle of 135 degrees.

The diameter of the hinge core is 8mm, and the core is installed by installing screws on the hinge block to fix the hinge core on one of the hinge blocks. This mounting method is more secure. This hinge is available in three sizes, as shown in the detailed dimensional drawings and tables below.

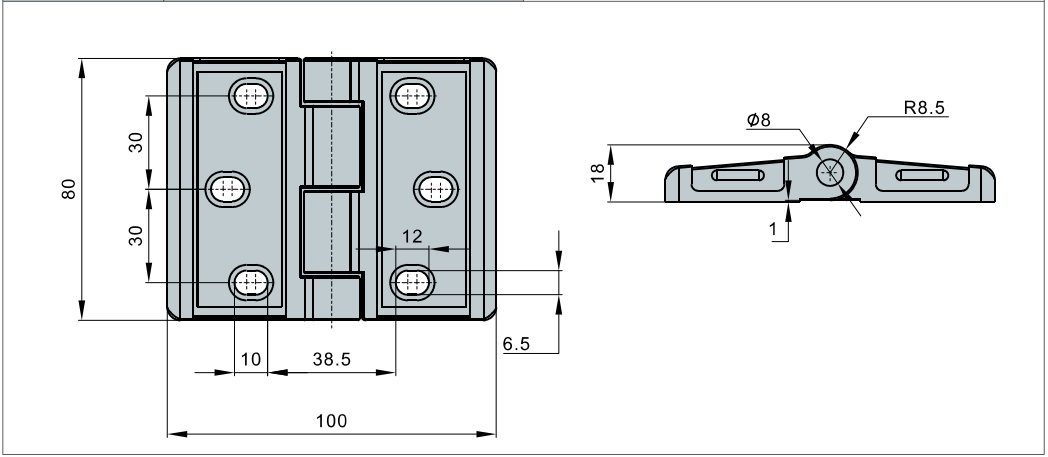

The second gate heavy-duty hinges

It is made of zinc alloy with a bright chrome-plated finish. The mounting holes are designed with long round holes, and the position can be adjusted during installation, with a maximum opening angle of 135 degrees, with a mounting cover plate. The appearance is simple and beautiful. The structure is similar to the previous model. This hinge also has an 8mm core and an 80*100mm exterior dimension and is available in only one size. The weight of the hinge is 570g, and the detailed dimensions are shown below.

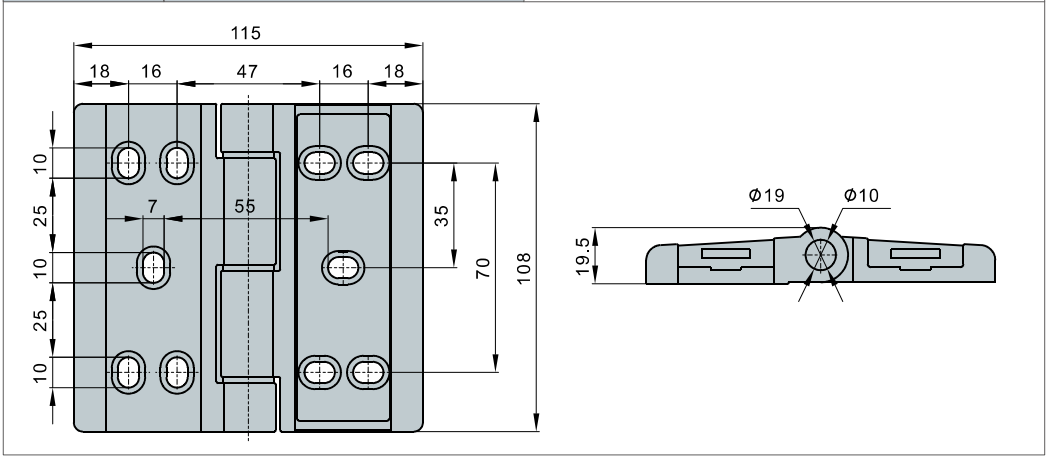

The third gate heavy-duty hinges

The third model is larger than the first two models, with an external dimension of 115*108mm. It has two specifications for the two hinge blocks, the first specification for the horizontal and vertical holes, and the second specification for all horizontal holes. Only the specifications of the horizontal and vertical holes are shown in the size chart below. The picture shows the specification of all horizontal holes.

It has a hinge core diameter of 10mm, which is also designed with a long round hole and can also be adjusted during installation. There are nylon spacers between the hinge knuckles to provide cushioning and silence. The figure below shows the detailed dimensions.

The fourth gate heavy-duty hinges

The fourth heavy-duty door hinge is made of two materials, zinc alloy, and stainless steel. The size of both materials is the same. The hinge has a core diameter of 8mm and a profile size of 100*100mm, with a long round hole and a stainless steel cover. The maximum opening angle is 135 degrees, and the detailed dimensions are shown below.

The fifth gate heavy-duty hinges

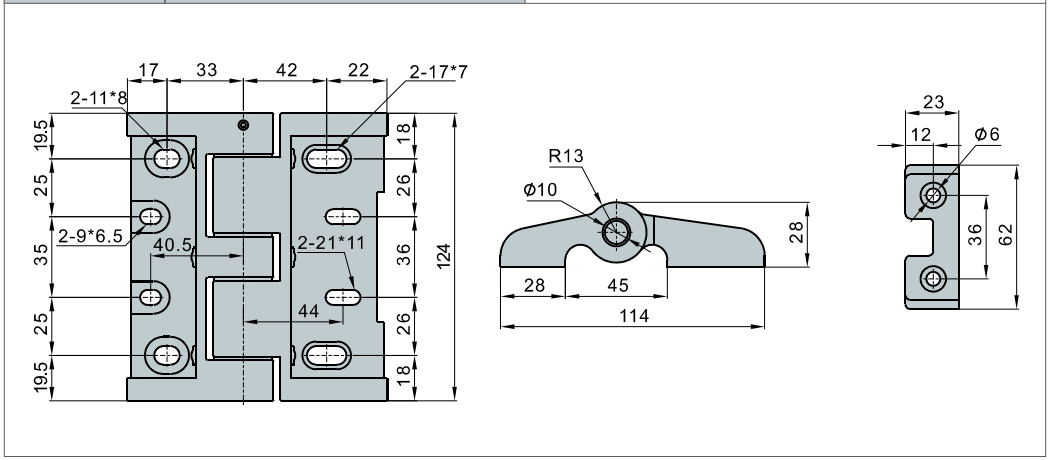

The fifth gate heavy-duty hinge is an oversized specification with an external dimension of 114*124mm, made of zinc alloy with a surface treatment of pearl chrome plating, and the installation hole is designed as a long circle, which can be adjusted by 10mm horizontally to adjust the sealing degree of the door. Please be sure to adjust the position before tightening the screws during installation. This heavy-duty hinge has a 10 mm diameter core, and the core is screwed in place. The following is a detailed dimensional drawing.

The sixth

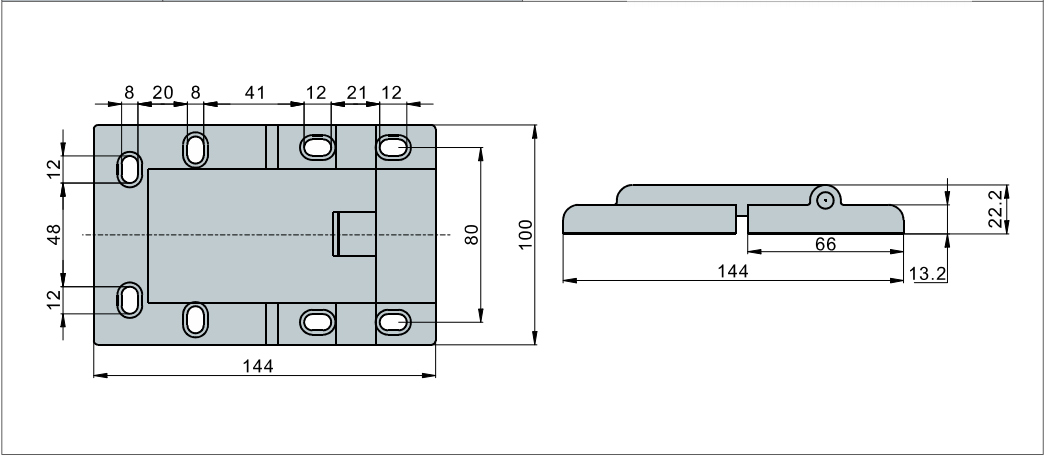

The sixth gate heavy-duty hinge is produced in 201 stainless steel with a brushed and polished finish. It has a maximum opening angle of 180 degrees, which means that the door can be fully expanded. The outer dimension is 100*144mm, the hinge core diameter is 8mm, and the multi-hole design makes the installation more solid. The weight of a single piece is 711g, and the detailed dimensions are shown below.

The seventh

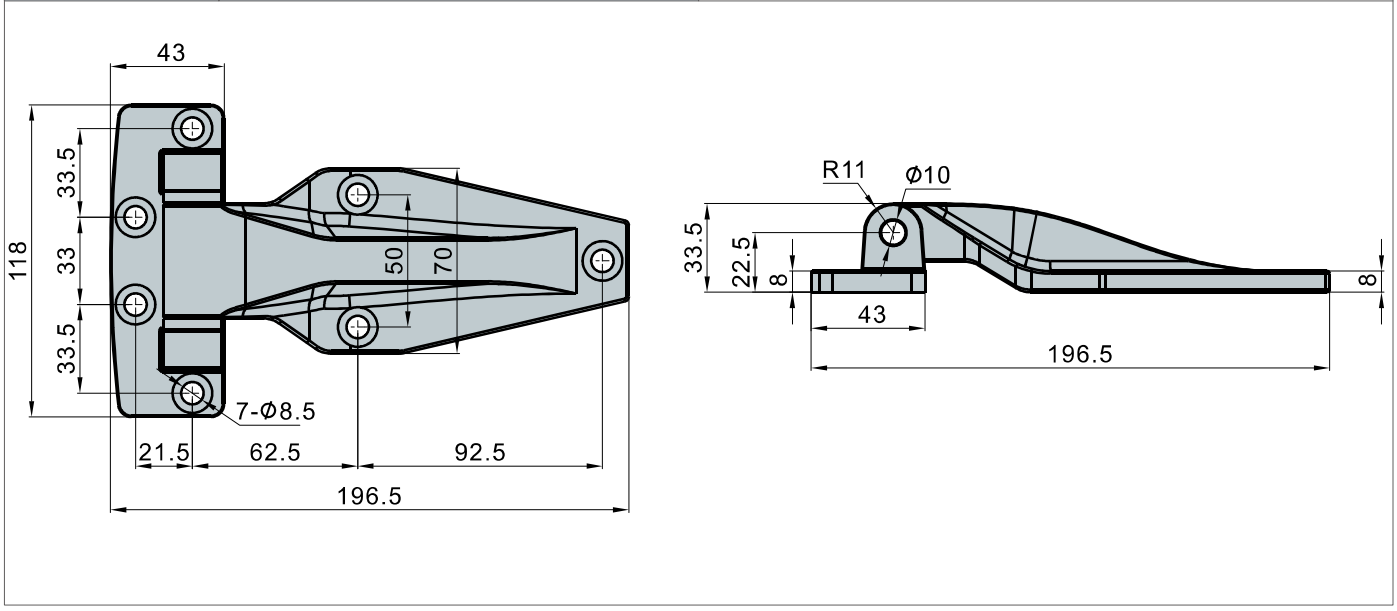

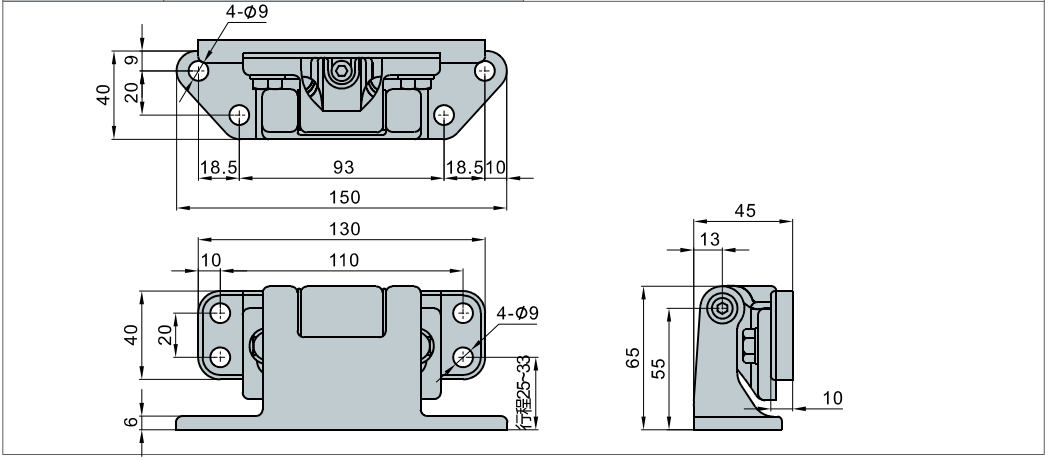

It is different from the previous six models in that it is installed with a step. That is, the door is not flush with the door frame, there is a step. It is made of stainless steel with a mirror-polished finish and weighs 1.25 KG. There is an adjustment screw in the middle of the hinge, which can be used to adjust the sealing level of the door and is suitable for installing seals of different thicknesses.

So, even without disassembling the hinge, the door sealing degree can be adjusted. However, when adjusting the hinge, the door needs to be lifted up to avoid the hinge having a load during the adjustment process. This hinge is very heavy, so care needs to be taken when installing it to prevent the hinge from falling and hitting your foot. Its external dimensions are 150*45*65mm, and the figure below shows the detailed dimensions.

The eighth

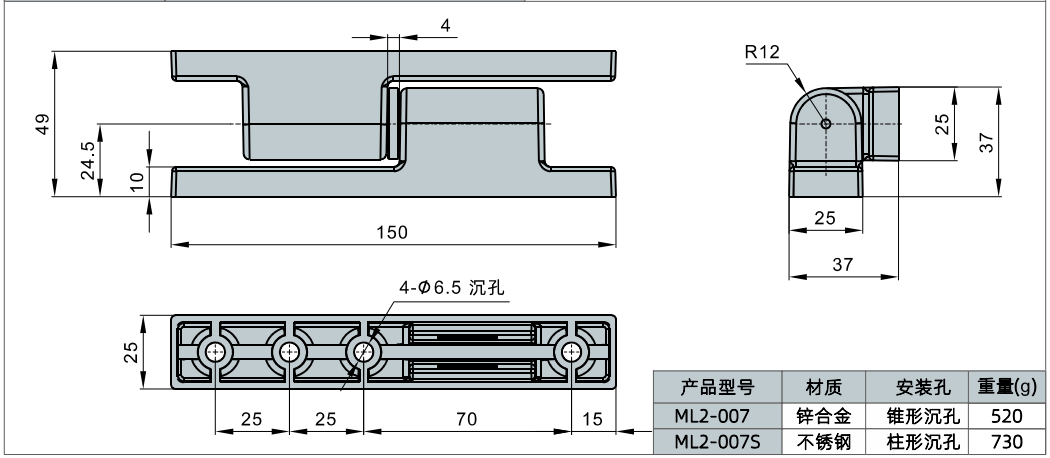

The eighth heavy-duty door hinge is also step-mounted. And it is a detachable hinge, about which we have a special page. It is available in two materials, zinc alloy and stainless steel. The surface treatment is bright chrome plated and mirror polished respectively. The dimensions are 150*49mm.

All parts of this hinge are removable, and the hinge core and spacer are removable. So the installation can be done by first installing the two hinge blocks and finally installing the door. However, this process requires strict determination of the size and position of the installation. Detailed dimensions are shown below.

The ninth gate’s heavy-duty hinges

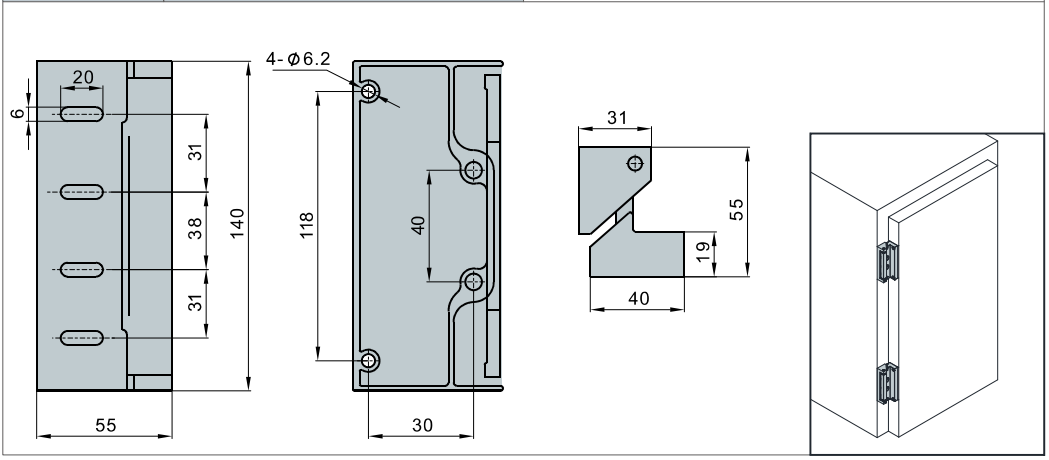

The ninth gate heavy-duty hinge is also step-mounted and is made of zinc alloy with two finishes: black sandblasted and bright chrome plated. The individual weight is 536 g. The hinge block has a long round hole on one side for easy position adjustment.

The hinge core is 6mm, processed in stainless steel, and metal spacers are used between the hinge blocks to play a buffering role. Overall dimensions are 118*55*55mm.

The tenth gate’s heavy-duty hinges

The last heavy-duty door hinge is also made of stainless steel with a mirror-polished finish. Single weight of 780g, hinge core diameter of 10mm. the maximum opening angle of 180 degrees, with a strong load-bearing performance, eat. The hinge block is an asymmetrical design on both sides, mainly because the door frame is generally narrower, while the door is wider, in order to comply with the door structure, the use of this design is reasonable, but also beautiful.