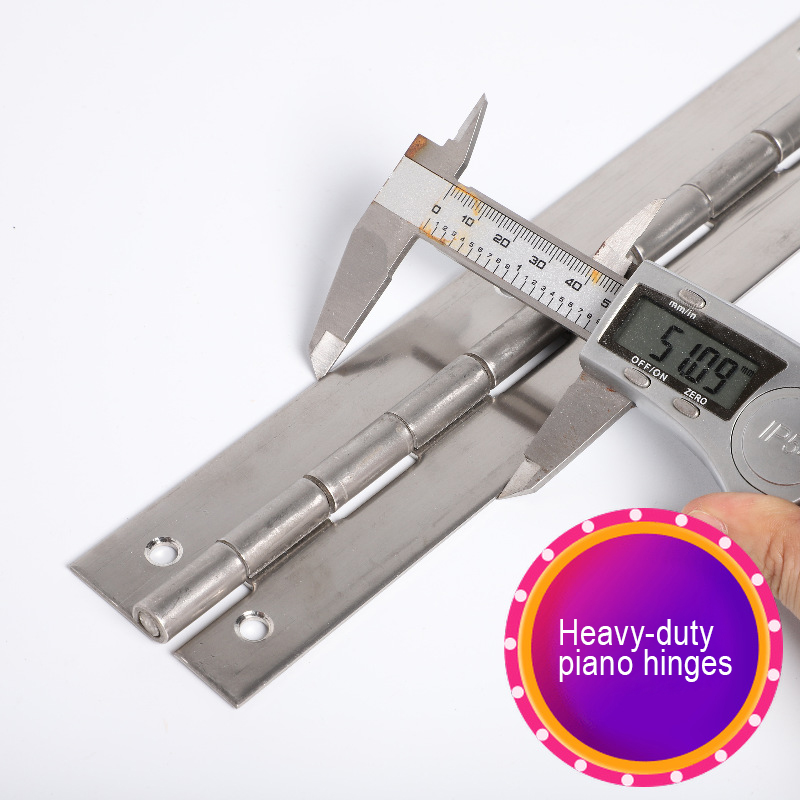

Heavy-duty piano hinges are a crucial component in various industrial settings due to their strength, durability, and ability to withstand high loads. In this article, we will explore the benefits and applications of piano hinges, which are typically constructed from materials such as stainless steel or brass, and designed to be used in challenging environments.

What are Heavy-duty Piano Hinges?

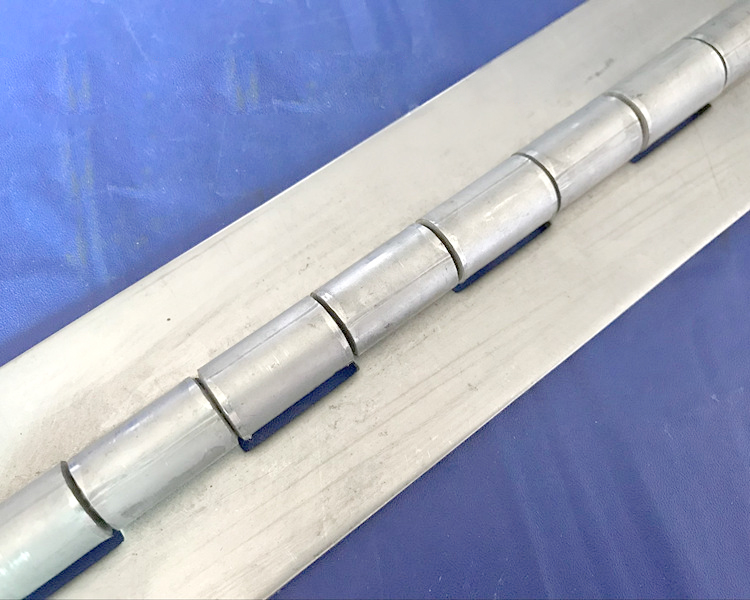

These hinges are long, narrow hinges that can be used to connect two objects horizontally. They are made of sturdy materials that are intended to bear heavy loads and are designed to offer resistance to wear and corrosion. They are typically constructed from materials such as brass or stainless steel and are often used in industrial applications where the weight and pressure of the load would cause other types of hinges to fail.

Piano hinges are engineered to offer smooth operation, as well as a secure and stable connection between the objects that they are connecting. They are available in various sizes, and the length of the hinge is typically several times the width of the hinge leaves, providing strength and durability.

Advantages of Heavy-duty Piano Hinges

Heavy-duty piano hinges offer several advantages over other types of hinges, which makes them a popular choice for heavy-duty applications. One of the primary benefits is their strength and durability, which makes them ideal for use in industrial environments. These hinges are designed to bear heavy loads and can withstand extreme pressure, making them perfect for use in challenging applications.

Another advantage of the hinges is their resistance to corrosion and wear. These hinges are designed to be used in harsh environments, where they may be exposed to moisture, chemicals, or other corrosive materials. They are typically constructed from high-quality materials, which ensures that they will last for a long time and require minimal maintenance.

Applications of Heavy-duty Piano Hinges in the Aerospace Industry

The aerospace industry requires high-quality components that are reliable, durable, and able to withstand extreme conditions. Heavy-duty piano hinges are used extensively in the aerospace industry, primarily in applications such as aircraft doors, access panels, and landing gear doors.

These hinges are designed to provide a secure and robust connection between components, ensuring safe operation in extreme conditions. Piano hinges are also resistant to wear and corrosion, making them an ideal choice for use in harsh environments.

Applications of Heavy-duty Piano Hinges in the Automotive Industry

The automotive industry requires durable components that are designed to withstand the rigors of daily use. Heavy-duty piano hinges are used extensively in the automotive sector, primarily in applications such as the hood and trunk hinges, door hinges, and seat brackets.

These hinges are designed to bear heavy loads and provide a stable and secure connection between components. They are engineered to withstand extreme pressure, ensuring that they will last for a long time without requiring frequent maintenance.

Applications of Heavy-duty Piano Hinges in the Manufacturing Industry

The manufacturing industry requires high-quality components that are reliable and able to withstand harsh conditions. These hinges are used extensively in the manufacturing sector, primarily in applications such as machinery doors, tool boxes, and access panels.

These hinges are designed to provide a robust and secure connection between components, ensuring safe operation in harsh environments. The hinges are also resistant to wear and corrosion, making them an ideal choice for use in industrial settings.

Customization Options for Piano Hinges

Heavy-duty piano hinges can be customized to meet specific requirements, which is another advantage of using these hinges in industrial applications. Customization options include different materials, sizes, finishes, and mounting options.

Customized hinges can be designed to withstand extreme temperatures, corrosive environments, and heavy loads. This makes them an ideal choice for use in challenging applications, where off-the-shelf components may not be suitable.

Maintenance and Care of Piano Hinges

Heavy-duty piano hinges are designed to be durable and long-lasting, but regular maintenance and care can help prolong their lifespan. It is essential to keep the hinges clean and free of debris, which can cause wear and tear over time.

To clean the hinges, simply wipe them down with a soft cloth and a mild cleaning solution. Avoid using abrasive cleaners or steel wool, which can damage the finish of the hinge.

Lubricating the hinges is also crucial for smooth operation. Use a high-quality lubricant, such as silicone or graphite, to keep the hinges working correctly. It is important to avoid using oil-based lubricants, which can attract dust and dirt and cause the hinges to wear out faster.

Choosing the Right Heavy-duty Piano Hinges

When choosing heavy-duty piano hinges. It is essential to consider the specific requirements of the application. Factors to consider include the weight of the load, the environmental conditions, and the mounting options.

It is also crucial to select high-quality hinges from reputable manufacturers to ensure that they will meet the required standards and perform as expected. Look for hinges that are constructed from durable materials. They have a strong load-bearing capacity and are resistant to wear and corrosion.

Conclusion

Heavy-duty piano hinges are a crucial component in various industrial applications, offering strength, durability, and resistance to wear and corrosion. They are used extensively in aerospace and automotive. And manufacturing industries, among others, can be customized to meet specific requirements.

Proper maintenance and care are essential to prolonging the lifespan of the hinges. Including regular cleaning and lubrication. When selecting heavy-duty piano hinges. It is essential to consider the specific requirements of the application and choose high-quality hinges from reputable manufacturers.