Purchasing the right hardware for your doors can significantly affect their functionality and longevity. Spring loaded hinges are a popular choice for ensuring doors close automatically, providing convenience and safety in various settings.

However, with the myriad of options available, it’s crucial to understand the specifics before making a purchase. This guide will navigate through the essential aspects, ensuring you make an informed decision suited to your needs.

Choosing the right spring loaded hinges can enhance door performance, security, and aesthetics. Let’s delve deeper into what you need to consider.

Different types of spring loaded hinges and their applications

Spring loaded hinges come in various designs, each tailored to specific applications and requirements. From single-acting hinges for standard doors to double-acting ones for saloon or café-style doors, the choice depends on the door’s operation and the desired closing mechanism. Additionally, there are surface mount and concealed options, affecting the hinge’s visibility and the door’s overall appearance.

Understanding the application is key; for instance, heavy-duty hinges are suitable for entry doors or gates, while lighter versions are ideal for interior doors. The environment also plays a role; certain materials and finishes are better suited for outdoor use, offering resistance to weather conditions.

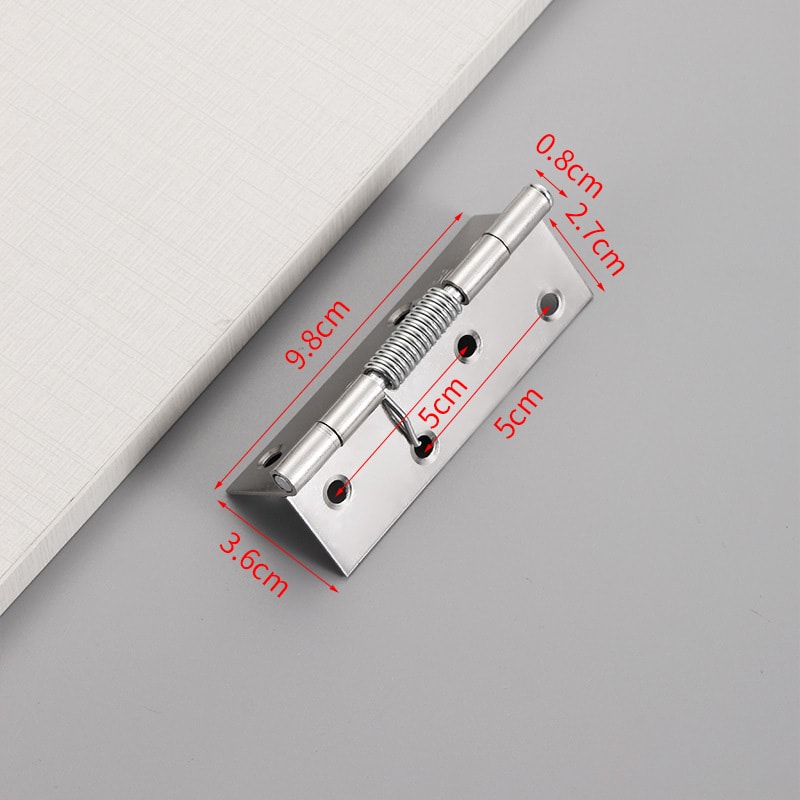

How to choose the right spring loaded hinge based on door size and weight

Selecting a hinge that matches the door’s size and weight is crucial for its proper function. A hinge that’s too weak may fail to close the door completely, while an overly strong one can cause wear or damage. The hinge’s specifications usually include a maximum door size and weight limit, guiding the selection process.

It’s also important to consider the door’s frequency of use. High-traffic areas may require more durable hinges, capable of withstanding numerous cycles without losing tension or effectiveness.

This also needs to be considered in the field of some industrial equipment, such as piano hinges that are load-bearing but also have to take into account the question of how often it will be used.

Installation and adjustment tips for spring loaded hinges

Proper installation and adjustment are paramount for the optimal performance of spring loaded hinges. Ensuring correct alignment and spacing can prevent issues such as door sagging or improper closing. Most hinges allow for tension adjustment, enabling the fine-tuning of the closing force to match the door’s requirements.

Tools and hardware needed for installation should be verified beforehand, and following the manufacturer’s instructions closely will aid in achieving the best results. Additionally, understanding the adjustment mechanism will allow for easy maintenance and adjustments over time.

Comparison of spring loaded hinges with other hinge types

When comparing spring loaded hinges to other types, such as soft-close hinges, consider the closing mechanism and application. Spring loaded hinges are designed for automatic closing with a certain force, while soft-close hinges aim for a gentle closing, reducing noise and impact.

The choice between these hinges often comes down to the desired door function and the environment in which they will be used. For instance, soft-close hinges might be preferable in quiet areas or where gentle closing is a priority.

Maintenance and care methods for spring loaded hinges

Maintaining spring loaded hinges ensures their longevity and proper function. Routine checks for loose screws and applying lubricant can prevent squeaking and wear. It’s also advisable to periodically adjust the tension, especially if the door’s closing speed changes over time.

Following the manufacturer’s maintenance recommendations will help in preserving the hinges’ condition, avoiding the need for premature replacements.

Performance and requirements of spring loaded hinges in specific applications

Certain applications, such as fire doors or furniture, may have specific requirements for hinges. Fire doors, for instance, require hinges that can withstand high temperatures and ensure the door closes in case of a fire. We usually use industrial stainless steel hinges. Similarly, furniture doors might need smaller, more aesthetically pleasing hinges that still provide the necessary functionality.

Understanding these specific needs is crucial when selecting hinges, as it ensures compliance with safety standards and achieves the desired outcome.

Conclusion

Choosing the right spring loaded hinges requires consideration of their types, application, installation, comparison with other hinges, maintenance, and specific requirements. By keeping these factors in mind, you can ensure the functionality, safety, and aesthetics of your doors. Remember, the right hinge not only complements your door but enhances its performance and longevity.

You might be interested: