Pallet collars are an essential part of logistics and storage, offering a flexible, cost-effective, and durable solution for various storage and transport needs. At the heart of these ingenious systems are pallet collar hinges, the unsung heroes that make the adaptability of pallet collars possible. Understanding these components is crucial for anyone involved in warehousing, logistics, or supply chain management.

Pallet collar hinges are pivotal in the functionality of pallet collars, transforming standard pallets into versatile storage solutions. These hinges are not just mere connectors; they play a significant role in the safety, efficiency, and adaptability of pallet collars, influencing how goods are stored and transported.

In this article, we delve into the intricacies of pallet collar hinges, uncovering their types, materials, design considerations, installation, maintenance, and environmental impact.

Pallet collar hinges might seem like a small cog in the vast machinery of logistics, but their importance cannot be overstated. Join us as we explore the world of these vital components, and discover how they can revolutionize your storage and transport processes.

Types of Pallet Collar Hinges

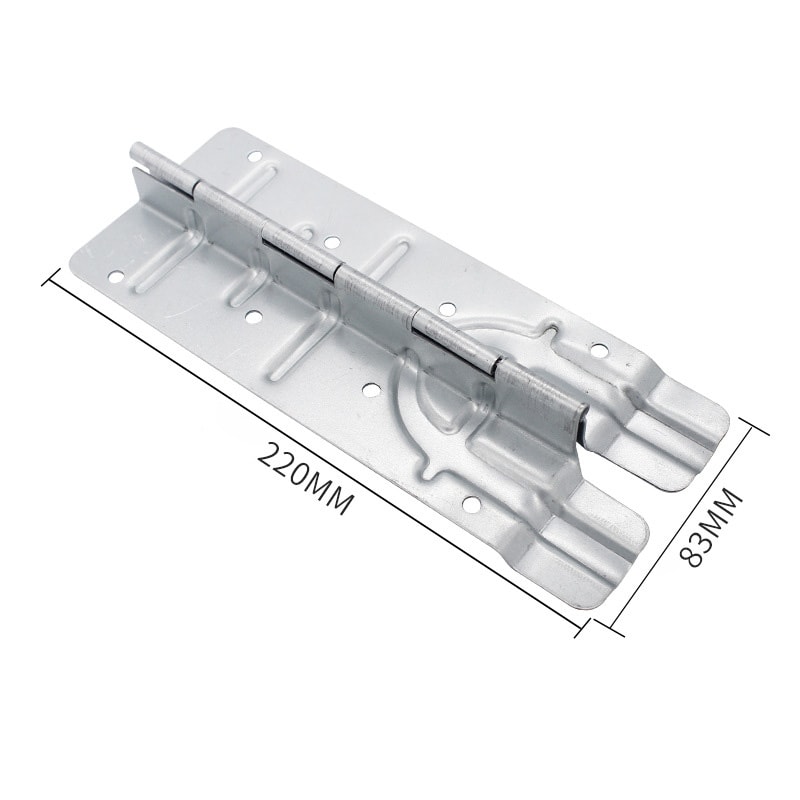

Pallet collar hinges come in various types, each designed to suit specific needs and applications. The most common types are fixed, flexible, and lockable hinges. Fixed hinges are permanently attached to the collar, offering robustness and durability. Flexible hinges, on the other hand, allow the collars to fold flat when not in use, saving valuable space. Lockable hinges provide an added security feature, ensuring that the contents of the pallet collar are secure during transport.

Each type of hinge has its unique advantages and is suited for different scenarios. Fixed hinges are ideal for heavy-duty use, where the pallets undergo frequent movement and handling. Flexible hinges are perfect for businesses that require efficient storage solutions, as they allow for easy collapsibility and stacking of the pallet collars. Lockable hinges are essential in situations where the security of the goods is paramount, such as in the transportation of high-value items.

Materials Used in Pallet Collar Hinges

The material of a pallet collar hinge plays a crucial role in its performance and longevity. The most commonly used materials are steel, aluminum, and plastic. Steel hinges are known for their strength and durability, making them suitable for heavy-duty applications. Aluminum hinges are lighter, making them easier to handle and ideal for applications where weight is a concern. Plastic hinges are corrosion-resistant and often more cost-effective, but they may not be as durable as their metal counterparts.

When choosing the material for a pallet collar hinge, it’s essential to consider the specific needs of your operation. Steel hinges are the go-to choice for most heavy-duty applications, but if weight or corrosion resistance is a concern, aluminum or plastic might be the better option. The environment in which the pallets will be used, such as exposure to chemicals or extreme temperatures, should also be taken into account when selecting the material.

Design Considerations for Pallet Collar Hinges

The design of pallet collar hinges is critical for their functionality and ease of use. Key design considerations include the hinge’s load capacity, ease of installation, and compatibility with different pallet sizes and types. The load capacity determines how much weight the hinge can support, which is crucial for preventing accidents and ensuring the safety of the stored goods. The ease of installation impacts the time and effort required to set up the pallet collars, while compatibility with different pallet sizes and types ensures versatility and adaptability in various storage scenarios.

Innovative designs in pallet collar hinges can also enhance their functionality. For example, hinges with built-in safety features, such as locking mechanisms, can prevent accidental opening during transport. Ergonomically designed hinges can make the assembly and disassembly of pallet collars faster and more comfortable for workers.

Installation and Maintenance of Pallet Collar Hinges

Proper installation and maintenance are vital for the longevity and functionality of pallet collar hinges. Installation procedures vary depending on the type of hinge and the design of the pallet collar. It’s essential to follow the manufacturer’s instructions to ensure that the hinges are correctly installed and that the pallet collars function as intended. Regular maintenance, including cleaning, lubrication, and inspection for damage or wear, can significantly extend the life of the hinges and prevent potential failures.

Training staff on the correct handling and maintenance of pallet collars and their hinges is also crucial. This training can reduce the likelihood of damage due to improper handling and ensure that any issues with the hinges are identified and addressed promptly.

Environmental Impact of Pallet Collar Hinges

In today’s eco-conscious world, the environmental impact of logistics and storage solutions is increasingly important. Pallet collar hinges, like all components of pallet systems, contribute to the overall environmental footprint of these solutions. The choice of materials, the manufacturing process, and the recyclability of the hinges are all factors that influence their environmental impact.

Choosing hinges made from recyclable materials, such as certain metals or plastics, can reduce the environmental impact. Additionally, selecting hinges designed for durability and long life can minimize waste and the need for frequent replacements. Manufacturers are also adopting more sustainable practices, such as using recycled materials and reducing emissions in the production process, to make pallet collar hinges more environmentally friendly.

Conclusion

Pallet collar hinges are a small but crucial component in the logistics and storage industry. Understanding their types, materials, design considerations, installation and maintenance, and environmental impact is essential for anyone looking to optimize their storage and transport solutions. By choosing the right hinges and maintaining them properly, you can enhance the safety, efficiency, and sustainability of your pallet collars.

You might also be interested: