The wrong hinge can compromise the functionality of an industrial drying oven, leading to mechanical failure or safety hazards. Choosing the right hinge can eliminate operational risks and ensure durability.

Industrial drying oven hinges differ from ordinary hinges in several critical aspects, including appearance, manufacturing process, surface treatment, installation methods, packaging, and customer base.

Keep reading to understand the six key differences between these hinge types.

Differences in Appearance

Industrial drying oven hinges are built to handle heavy-duty applications, making them appear more robust and larger than ordinary hinges. Their design often includes reinforced joints and thicker materials to withstand high-temperature conditions and frequent use. In contrast, ordinary hinges, such as Butt Hinges, are generally smaller and designed for lighter applications, where aesthetics may play a bigger role than durability.

Due to their purpose, industrial hinges focus on function over form, often lacking the sleekness or decorative elements seen in home-use hinges. The added weight and size also contribute to their distinct appearance, ensuring that they can support the heavy doors of industrial equipment.

Differences in Manufacturing Process

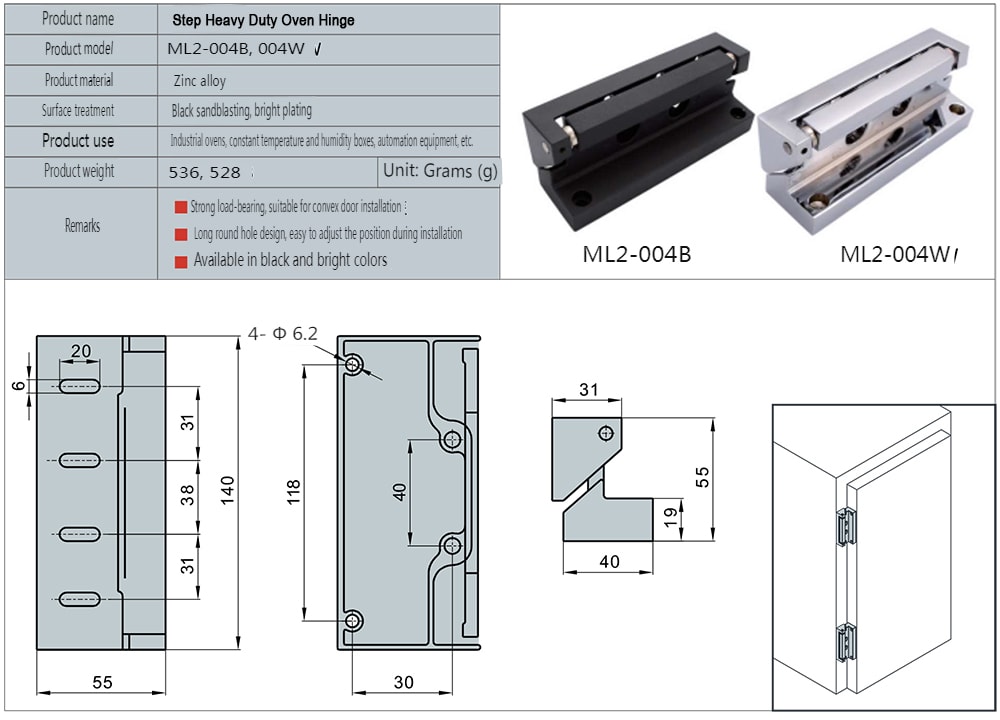

Industrial drying oven hinges are crafted using more rigorous methods, such as zinc alloy casting or stainless steel casting. These processes allow the hinges to bear more weight and endure harsher conditions, especially in high-temperature environments like industrial ovens. Materials like stainless steel resist corrosion and can handle the constant heat fluctuations typical in industrial settings.

On the other hand, ordinary hinges are often made using simpler materials and processes, such as steel stamping, which is sufficient for lighter applications. Ordinary hinges, such as Piano Hinges, are used in applications where weight-bearing isn’t as critical, and durability requirements are more relaxed.

Differences in Surface Treatment

The environmental demands of industrial ovens require hinges with specialized surface treatments. Industrial hinges are frequently coated with heat-resistant, corrosion-proof materials such as powder coatings or electroplating, ensuring that they can endure both high temperatures and exposure to chemicals. This level of treatment prevents rust and extends the lifespan of the hinge in harsh industrial environments.

Ordinary hinges, in contrast, typically undergo basic surface treatments like painting or simple plating, which is adequate for indoor or low-stress environments. Since these hinges aren’t exposed to extreme conditions, their coatings primarily focus on preventing wear and maintaining appearance rather than performance.

Differences in Installation Methods

Installation methods differ significantly between industrial drying oven hinges and ordinary hinges. Many industrial hinges are installed using screws, but for added stability and safety, some models require welding to the equipment. This ensures that the hinge remains securely attached even under heavy strain, preventing any detachment that could result in costly repairs or dangerous accidents.

Ordinary hinges, like those used in home cabinets, are almost exclusively screwed into place, as the loads they bear are minimal, and welding is unnecessary. These hinges are designed for easy installation and replacement, often catering to individual consumers who value convenience over durability.

Differences in Packaging

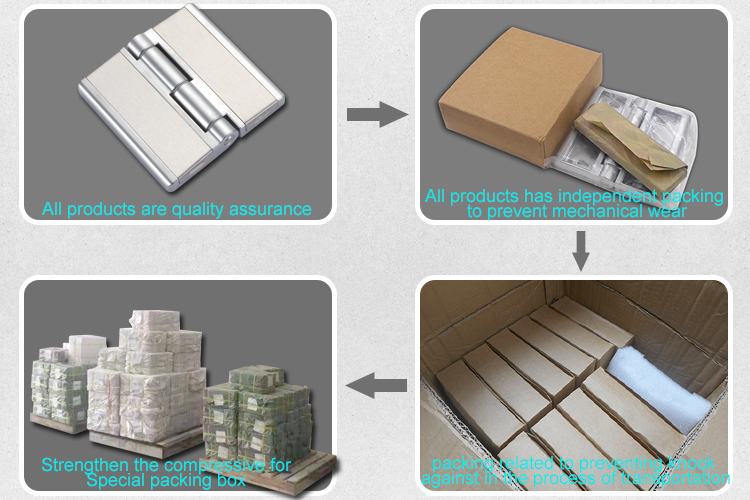

When it comes to packaging, industrial hinges prioritize practicality over presentation. Since these hinges are typically used by manufacturers and industrial clients, the primary focus is on ensuring that the product arrives intact. The packaging is designed to protect the hinge during transportation, especially given its size and weight, but there is little emphasis on aesthetics.

In contrast, ordinary hinges, particularly those sold to consumers for home use, often come in attractive packaging designed for retail shelves. Decorative packaging and branding help catch the eye of the consumer, even though the product may not require such protection during transit.

Differences in Target Customer Groups

The customer base for industrial drying oven hinges primarily consists of businesses and factories that operate heavy machinery or large-scale equipment. These customers require durable, long-lasting products that can be customized to fit specific industrial needs. Industrial clients, including those purchasing Heavy Duty Hinges or Climatic Test Chamber Hinges, look for performance over aesthetics.

In contrast, ordinary hinges are often bought by individual consumers or small businesses looking for simple, cost-effective solutions. These buyers may not prioritize the same level of performance, focusing instead on finding affordable and easy-to-install products for household projects.

Conclusion

Industrial drying oven hinges are distinctly different from ordinary hinges in appearance, manufacturing, and functionality. These differences are critical for businesses looking for reliable, high-performance hardware for demanding environments.

Need to browse related hinges products: Heavy Duty Hinges

You may be interested in: