If you open the door at the same time, the door will rise upward, and when you close the door, it will come down again back to its original position. Would you find that amazing? The key to this is the hinges on the door. These hinges are what we call cam lift hinges.

This is a type of hinge that is specifically used on industrial equipment doors. It has a unique design that sets it apart from other traditional hinges. I will describe it in the following 5 ways.

What is a cam lift hinge?

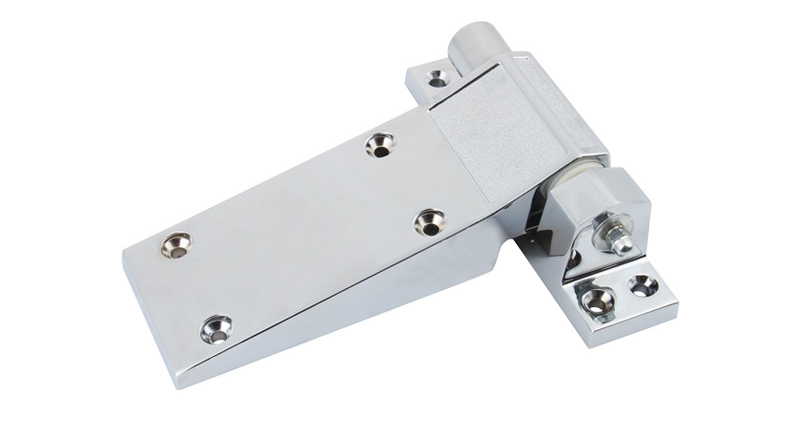

It belongs to the category of heavy-duty hinges used in industrial equipment. This type of hinge will rise or fall during rotation. This is mainly due to the special design of the hinge shaft. This allows the door to lift up as it opens and lands in place as it descends.

The purpose of this design is to achieve a tighter seal. When the door is closed, it is pressed down along the shaft due to the force of gravity. This allows the seal to remain in a compressed state. The sealing effect is thus achieved. No other forces are exerted, the earth’s gravity is at work.

What are the features of the cam lift hinge?

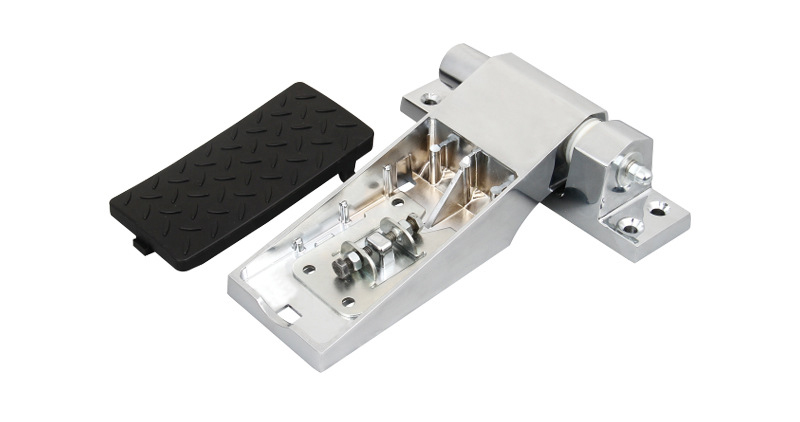

The feature of this hinge is that it can be lifted and lowered. It has been described in the above article. This type of hinge requires friction between the shaft and the axle. That is why the production of the hinge shaft is very important. The common material used for production is nylon rod or stainless steel 304 with superb wear resistance.

In addition, cam lift hinges have good sealing performance. In industrial equipment, there are many devices that need to be sealed. For example, constant temperature and temperature test chamber, industrial oven, and cold and thermal shock test chamber. There is also various refrigeration equipment in the field of refrigeration. In these areas can use this kind of hinge with good sealing performance.

What materials are used for cam lift hinges?

Common materials used for cam lift hinges are generally zinc alloy and stainless steel 304 or 316. If zinc alloy is used, the hinge core is usually made of nylon rod with good wear resistance. The nylon rod is nested inside the zinc alloy as the key component for lifting and lowering.

If it is made of stainless steel 304 or 316, then the same stainless steel shaft can be used as the key component for lifting and lowering. But no matter which material is used, the transfer part needs to be lubricated. This is very critical, otherwise, there is a risk that the life of the hinge will be greatly reduced.

What are the uses of cam lift hinges?

Due to the good sealing characteristics of the cam lift hinge. It allows it to be used on a variety of equipment doors that need to be sealed. The most common use is in refrigeration equipment. In refrigeration applications, sealing is an important aspect. If a walk-in freezer or commercial refrigerator has a leak, it will lose cold air. This results in the inability to maintain a specific low temperature inside the box, which can lead to food spoilage resulting in a loss.

Practical applications

With cam lift hinges, you can create an airtight seal on the door of a refrigeration system. The cam lift hinge will lift the door with which it is used. When you open the door of the refrigeration system, the cam lift hinge will allow it to move up slightly. When you close the refrigeration system door, the cam lift hinge will put the door back into its original position while creating an airtight seal.

Reliable construction

Most cam lift hinges are made of steel. They are characterized by strong load-bearing properties. More doors for refrigeration systems can be accommodated. Cam lift hinges come in different sizes and styles, but most of them have a long steel leaf.

Refrigeration system doors are very heavy. The hinges used with them must be able to support their weight. So the structural design of these hinges needs to be very reliable and sturdy.