In the industrial sector, the use of high-quality and reliable components is crucial for ensuring efficiency, safety, and durability. Among these components, spring-loaded hinges play a vital role in various applications.

In this article, we will explore the different types of industrial spring-loaded hinges, their benefits, factors to consider when selecting them, installation and maintenance tips, common uses across industries, a comparison with standard hinges, techniques to improve lifespan and durability, safety features and considerations, innovations in hinge technology, and troubleshooting common issues. Let’s delve into the world of industrial spring-loaded hinges and discover how they optimize industrial applications.

What are industrial spring-loaded hinges?

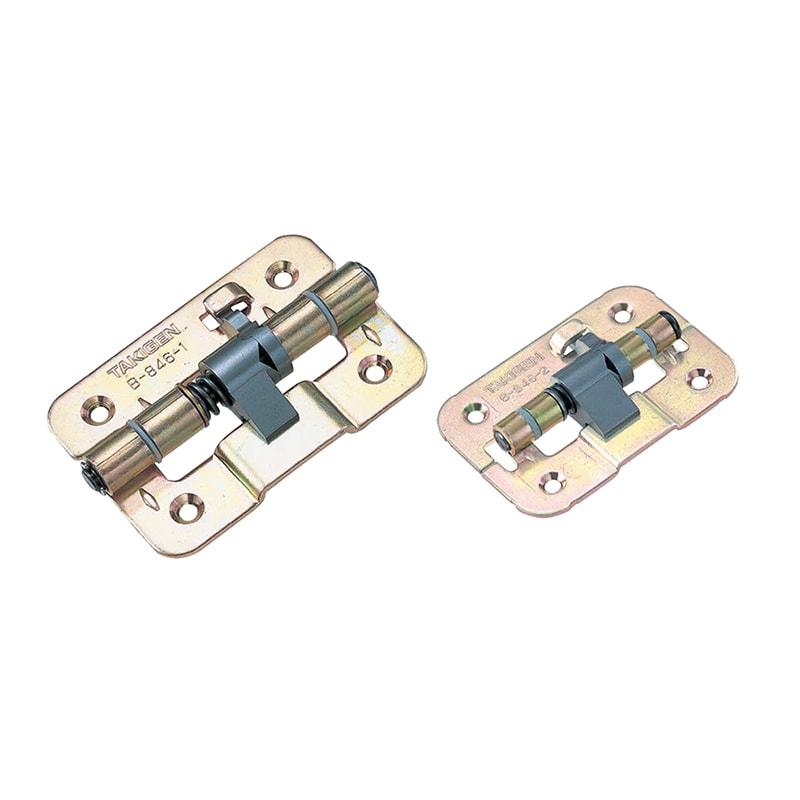

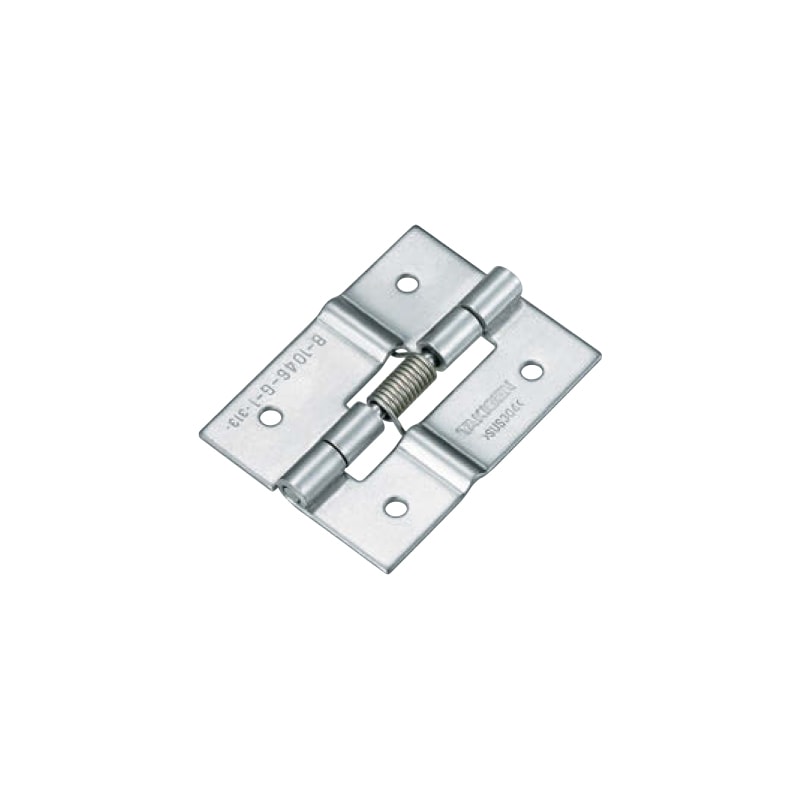

Industrial spring-loaded hinges, also known as self-closing hinges or self-opening hinges, are mechanical devices used in various industrial applications. These hinges are designed to provide automatic closing or opening action, depending on the specific use case.

The main component of an industrial spring-loaded hinge is a built-in spring mechanism. This mechanism applies force to the hinge, enabling it to return to its default position after being opened or closed. The spring can be adjusted to control the speed and force of the hinge’s movement.

Types of Industrial Spring-Loaded Hinges:

Industrial spring-loaded hinges come in a range of configurations to suit different requirements. Some common types include:

- Concealed Spring-Loaded Hinges: These hinges are designed to provide a clean and streamlined appearance as they are installed inside the door or frame, ensuring a seamless look without compromising functionality.

- Adjustable Spring-Loaded Hinges: These hinges offer flexibility by allowing adjustment of the spring tension according to specific needs. This adjustability ensures optimal performance and adaptability to various load requirements.

Advantages of industrial spring-loaded hinges:

The utilization of spring-loaded hinges in industrial settings provides several advantages. Firstly, they offer controlled movement and assist in the effortless opening and closing of heavy doors or panels. This reduces strain on operators and enhances overall operational efficiency. Secondly, spring-loaded hinges contribute to noise reduction by dampening vibrations and preventing slamming or abrupt closure, creating a quieter and more comfortable working environment. Additionally, these hinges promote safety by preventing doors from accidentally closing or opening due to sudden air pressure changes or external factors. Furthermore, spring-loaded hinges facilitate precise alignment and positioning, ensuring accurate and repeatable operations in manufacturing processes.

How to choose an industrial spring-loaded hinge?

Choosing the right industrial spring-loaded hinge requires careful consideration of several factors. Firstly, it is essential to assess the load capacity requirements. Industrial applications often involve heavy doors or panels that exert significant weight and force on the hinges. Ensuring that the chosen hinges can withstand these loads without compromising performance or safety is crucial. Manufacturers provide load capacity ratings for their hinges, and selecting hinges with appropriate load-bearing capabilities is essential for optimal functionality.

Secondly, evaluating the environmental conditions is vital in selecting the most suitable spring-loaded hinges for industrial applications. Industrial settings can present various challenges such as temperature variations, exposure to corrosive substances, or high levels of moisture. It is important to choose hinges made from materials and coatings that can withstand these environmental factors and maintain their durability over time. For example, stainless steel hinges are often preferred for their corrosion resistance, while certain coatings provide protection against extreme temperatures. By taking into account the specific environmental conditions in which the hinges will be used, businesses can ensure the longevity and reliability of their industrial applications.

How to install and maintain industrial spring-loaded hinges?

Proper installation is crucial for ensuring the optimal performance and longevity of industrial spring-loaded hinges. During the installation process, it is essential to focus on accurate alignment and secure mounting. Improper alignment can lead to stress or misalignment of the hinges, which can affect their functionality and cause premature wear. Ensure that the hinges are aligned correctly with the doors or panels they are attached to, following the manufacturer’s guidelines and recommendations. Additionally, secure the hinges firmly in place using appropriate mounting hardware to prevent any movement or instability.

Regular maintenance plays a significant role in preserving the performance and lifespan of industrial spring-loaded hinges. One essential maintenance task is lubrication. Lubricating the hinges with high-quality lubricants is crucial for ensuring smooth operation and minimizing friction. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication to achieve optimal results. Additionally, it is important to regularly inspect the hinges for any signs of wear, damage, or loose components. Conducting routine inspections allows for early detection of issues and enables timely repairs or replacements, preventing further damage and ensuring reliable performance.

What are the uses of industrial spring-loaded hinges?

Industrial spring-loaded hinges are widely used in various industries due to their versatility and reliability. One of the primary applications of these hinges is in heavy machinery and equipment, where they are crucial components in hydraulic systems, large-scale manufacturing plants, and industrial presses. These hinges enable smooth and controlled movement, ensuring the efficient operation of the machinery.

Aerospace:

They provide the necessary support and controlled movement for doors, panels, and cargo compartments in aircraft. These hinges contribute to the overall safety and functionality of aerospace structures, allowing for easy access and secure closure.

Automotive:

The automotive industry benefits from the use of spring-loaded hinges. They are commonly employed in hoods, trunk lids, and heavy doors, ensuring the safe and reliable operation of these components. Spring-loaded hinges provide the necessary strength and flexibility to handle the weight and movement of these parts, enhancing the overall functionality of vehicles.

Logistics, defense, energy, and pharmaceuticals:

In logistics, they enable the smooth functioning of doors, gates, and cabinets, facilitating efficient storage and transportation operations. In defense applications, these hinges are used in various equipment and vehicles to ensure durability and controlled movement. The energy industry utilizes spring-loaded hinges in power generation equipment, helping with the proper functioning of doors, access panels, and maintenance covers. Additionally, pharmaceutical industries rely on these hinges for cabinets, storage systems, and specialized equipment, ensuring secure and organized storage of medical supplies.

What is the difference between standard hinges and industrial spring hinges?

In contrast, spring-loaded hinges offer several benefits that make them particularly well-suited for industrial environments. One of their key advantages is the controlled and assisted movement they provide. The incorporation of a spring mechanism allows these hinges to apply a consistent closing or opening force, ensuring smooth and reliable operation. This can be especially valuable in situations where precise alignment is necessary, or when doors and panels need to be securely closed or opened with minimal effort.

Moreover, spring-loaded hinges are designed to withstand external influences that can affect the performance of standard hinges. They are typically more resistant to vibration, shocks, and fluctuations in temperature or pressure. This durability and resilience make spring-loaded hinges ideal for heavy-duty applications, where they can endure the demanding conditions commonly found in industrial environments.

In industrial settings where heavy doors or panels are involved, such as manufacturing plants, warehouses, or equipment enclosures, the advantages of spring-loaded hinges become even more apparent. These hinges provide the necessary support and control to handle the weight and movement of such components, ensuring smoother operation and minimizing the risk of accidents or damage.

How to Improve the Lifespan and Durability of Industrial Spring-Loaded Hinges:

Regular inspection:

Conducting routine checks allows you to identify any signs of wear or damage early on, enabling timely repairs or replacements. Inspect the hinges for any visible signs of corrosion, cracks, or misalignment, as these can significantly affect their performance and lifespan. Addressing these issues promptly can prevent further damage and ensure the hinges continue to function optimally.

Add lubrication:

Regularly apply lubricants specifically designed for hinges to reduce friction and wear. This helps to maintain smooth movement and prevents the hinges from seizing or sticking over time. When applying lubricants, ensure that they are compatible with the materials used in the hinges to avoid any adverse effects.

Alignment:

Misaligned doors can put excessive strain on the hinges, leading to premature wear and potential failure. Regularly check and adjust the alignment of doors to ensure they operate smoothly without putting undue stress on the hinges.

Avoid overloading:

Each hinge has a recommended weight or load limit, and exceeding this limit can lead to accelerated wear and potential damage. Be mindful of the weight and forces applied to the hinges, and if necessary, consider using additional hinges or alternative support mechanisms to distribute the load evenly.

Safety Features and Considerations for Industrial Spring-Loaded Hinges:

Safety is of utmost importance in industrial applications, and spring-loaded hinges incorporate various features to enhance it. Some hinges are equipped with adjustable spring tension, allowing fine-tuning of opening and closing forces to maintain safe operation. Others feature integrated dampening mechanisms to reduce the risk of sudden door movements or slams. Additionally, some hinges are designed with safety switches or sensors, enabling interlocking systems or signaling when doors are not securely closed. These safety features ensure a secure and protected working environment.

Innovations and Advancements in Industrial Spring-Loaded Hinge Technology:

The field of industrial spring-loaded hinges has witnessed significant advancements in recent years. One notable innovation is the integration of smart technologies, such as sensors or actuators, allowing for enhanced automation and remote monitoring. Furthermore, the development of specialized materials and surface treatments has improved the durability, corrosion resistance, and load-bearing capacity of hinges. Manufacturers are also focusing on eco-friendly designs, incorporating sustainable materials and manufacturing processes to reduce the environmental impact of hinge production.

Troubleshooting Common Issues with Industrial Spring-Loaded Hinges:

Despite their reliability, industrial spring-loaded hinges may occasionally encounter issues. Some common problems include misalignment, squeaking or excessive noise, reduced spring tension, or hinge component failure. To address these issues, perform a thorough inspection, ensuring proper alignment and lubrication. Replace any damaged or worn components and adjust the spring tension as necessary. If problems persist, consult the manufacturer’s guidelines or seek professional assistance to diagnose and resolve the specific issues affecting the hinges.

Conclusion:

Industrial spring-loaded hinges offer numerous benefits, including controlled movement, improved safety, and enhanced operational efficiency. By considering factors such as hinge types, selection criteria, installation and maintenance best practices, and safety features, businesses can optimize their industrial applications. Stay informed about the latest innovations and troubleshooting techniques to ensure the longevity and reliable performance of spring-loaded hinges in diverse industrial settings.