When it comes to durability and reliability in hinges, heavy-duty piano hinges stand out as the go-to solution for industrial and heavy-use environments.

These hinges are designed to withstand high levels of stress and use, making them ideal for applications where standard hinges simply won’t suffice. This post aims to demystify heavy-duty piano hinges, covering everything from their construction to their maintenance.

Understanding the specifics of heavy-duty piano hinges can significantly impact the success of your project, ensuring that you choose the right type of hinge for the job.

What are heavy duty piano hinges?

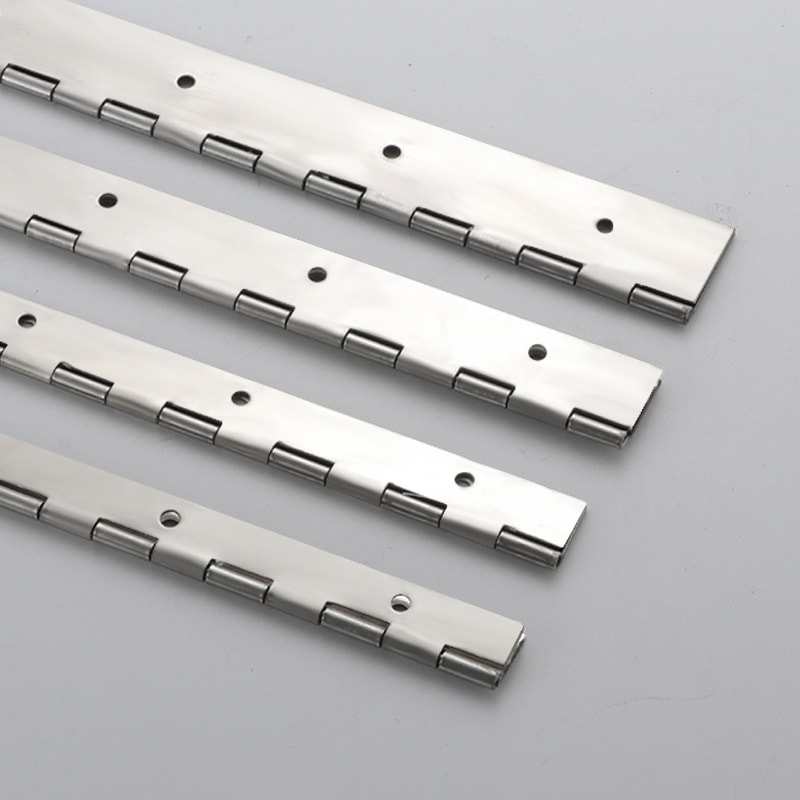

Heavy-duty piano hinges are robust, long hinges that provide continuous support along the entire length of the door or panel they are attached to. Made for industrial and heavy-use environments, these hinges are characterized by their strength, durability, and capacity to handle significant weight and usage over time.

Their design allows for even distribution of weight and stress, which minimizes wear and tear on both the hinge and the door, resulting in a longer lifespan for both components.

How do you install heavy duty piano hinges?

Installing heavy-duty piano hinges requires precision and the right tools to ensure they provide the maximum level of support and functionality. The process involves aligning the hinge perfectly with the door and frame, drilling pilot holes, and then securing the hinge with screws.

Proper installation is crucial for the hinge to perform as intended, supporting heavy doors without sagging or causing damage over time.

What materials are heavy duty piano hinges made from?

The materials used in the construction of heavy-duty piano hinges are selected for their strength and durability. Common materials include stainless steel, brass, and aluminum, each offering different benefits in terms of weight, corrosion resistance, and aesthetic appeal.

Choosing the right material depends on the specific needs of the application, including environmental conditions and the physical demands placed on the hinge.

What are the dimensions of heavy duty piano hinges?

Heavy-duty piano hinges come in a variety of sizes and lengths to accommodate different applications. Dimensions are crucial for ensuring the hinge can support the door or panel’s weight and size, with longer and thicker hinges available for particularly heavy or large doors.

Understanding how to select the correct dimensions is essential for the hinge’s performance and the longevity of the installation.

How much weight can heavy duty piano hinges support?

One of the key advantages of heavy-duty piano hinges is their ability to support substantial weight. The exact weight capacity depends on the hinge’s material, size, and design, with some models capable of supporting hundreds of pounds.

Knowing the weight capacity is crucial for applications that involve heavy doors or panels, ensuring safety and functionality.

Where can heavy duty piano hinges be used?

The versatility of heavy-duty piano hinges means they can be used in a wide range of applications. From industrial equipment doors to commercial-grade security doors and large storage cabinets, these hinges are suitable for any setting where durability and strength are paramount.

Their application extends beyond typical doors, including use in foldable tables, workbenches, and other heavy-duty furniture.

How do you determine the correct size of heavy duty piano hinge for your application?

Selecting the right size of heavy-duty piano hinge is critical for its performance. This involves considering the door’s width, height, and weight, as well as the hinge’s material and the load it needs to support.

A proper assessment ensures that the hinge can handle the door’s demands, preventing issues like sagging or premature wear.

Are heavy duty piano hinges corrosion-resistant?

Many heavy-duty piano hinges are designed with corrosion resistance in mind. Materials like stainless steel offer inherent resistance to rust and corrosion, making them ideal for outdoor or harsh environments.

However, the level of corrosion resistance varies by material, so it’s important to choose based on the environmental conditions the hinge will face.

Can heavy duty piano hinges be cut to size?

Flexibility in installation is another benefit of heavy-duty piano hinges, as many can be cut to size. This allows for a custom fit on doors or panels, ensuring that the hinge meets the exact specifications of the project.

Cutting hinges to size should be done with care to maintain the integrity and strength of the hinge.

How do you maintain and lubricate heavy duty piano hinges?

Regular maintenance and lubrication are key to extending the lifespan of heavy-duty piano hinges. Simple steps like cleaning the hinge and applying lubricant can prevent rust, reduce wear, and ensure smooth operation.

Maintenance routines depend on the hinge’s material and the environment it’s used in, with some requiring more frequent care than others.

Conclusion

Heavy-duty piano hinges are a critical component in many industrial and high-use applications, offering unmatched durability and support. Understanding these ten common aspects can help ensure that you choose the right hinge for your needs, guaranteeing performance and longevity.

As a professional industrial hinge manufacturer, we specialize in customizing industrial hinges to fit your equipment installation, ensuring quality while offering competitive prices. Feel free to contact us for a quote and enhance the functionality and durability of your projects.

You might be interested:

- Top 10 Common Things to Know Before Purchasing Brass Piano Hinges

- 10 Things to Know Before Purchasing Aluminium Piano Hinges

- 6 Things You Need to Know Before Purchasing Spring Loaded Hinges